Hello, readers welcome to the new post. In this post, we will learn How To Identify the Components of a Circuit Board. PCb boards main component of electronic projects and the device comes with a different component that operates to have an accurate function. The knowledge of these compone is required for preparing troubleshooting and modification of electronic devices. In this post, we will discuss differnt PCB components and learn how to Identify Components of a Circuit Board. Let’s get started with an Introduction to the components of a circuit board

Introduction Circuit Board Components

Circuit boards, also called printed circuit boards, are thin boards made of non-conductive materials like epoxy resin. or fiberglass. it is a material where different components are connected. The normal circuit board comes with a combination of active and passive components, connectors, and power supply components. Each component has its own function

Overview of and Parts of Circuit Board

.

Active Components of a Circuit Board

Active components are devices that can control curent flow. They need a power source to operate well. Here some active components used are explained

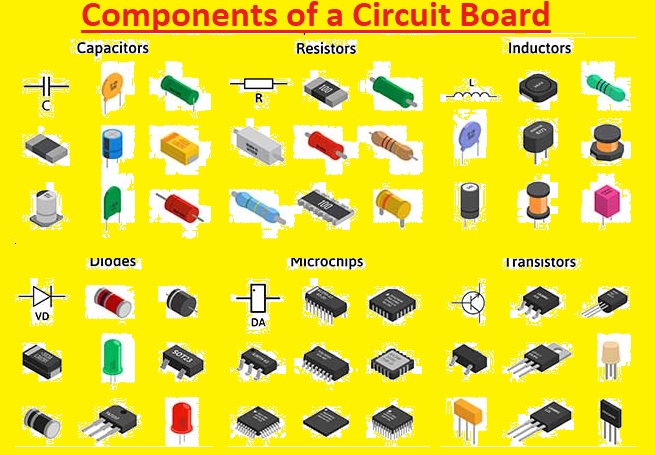

Transistors

Transistors are the basic components used for the amplification and switching of the circuit. Transisotr has two main types bipolar junction transistors and field-effect transistors.

Diodes

Diodes are devices that are used to convert AC into DC current. Allo current in one direction and stop in reverse direction. This process is called rectification and the circuit used is called a rectifier

Integrated Circuits

Integrated circuits are complex electronic devices configured on one chip. On a single chip, it can connect many components or millions of transistors. it is used to control different functions of devices

Operational Amplifiers

Operational amplifiers (op-amps) are high-gain voltage amplifiers used in analog circuits. They are used in filters, audio amplifiers, and signal-conditioning circuits.

Passive Components of a Circuit Board

Active components use power to operate the active component here are some commonly used passive components explained

Resistors

Resistors are used in the circuit to stop the current flow. They are good in current limiting, voltage division, and signal conditioning.

Capacitors

it is used for storing electrical energy and releases it when needed.. Used for smoothing power supply voltages, noise filtering, and timing in electronic circuits.

Inductors

It is coins of wire that store energy in the form of a magnetic field. it is used for energy storage, filtering, and impedance matching.

Transformers

Transformers are used to change the voltage level from high to low or low to high. They are used for voltage conversion, impedance matching, and isolation

Connectors and Interconnects

The connections between different components are made with connectors and interconnects. They help electrical signals and power between other components. Some commonly used connects are headers and ribbon cables, sockets, and wire-to-board connectors.

Power Supply Components

The power supply provides the needed voltage to circuits and current to work accurately They are voltage regulators, fuses power transistors, and circuit breakers.

Identifying Circuit Board Components Techniques and Tools

Visual Inspection

A visual inspection is done to check boards for identification of components with their structure, markings, and labels. Manufacturers have component reference numbers mentioned on the board for their proper identification

Circuit Board Schematics

These are detailed diagrams that explain the connection between components. They provdies the required data for types and component alignment on board

Multimeters and Oscilloscopes

Multimeters and oscilloscopes are used for measuring voltage, current resistance, and other parameters. it can help to find faults or error components by calculating their characteristics.

Troubleshooting Circuit Board Components

- Check teh board to find the damage due to overheating

- Measure voltage resistance and signal quality at different points on circuits with the use of a meter

- .Compares reading of required values from board layout

PCB Component Layout you Need to Know the Electronic Circuit

- Accurate component placement is required to have accurate board functionality. it comes with a configuration of components on board in the proper ways with measuring factors such as power distribution signal flow, and thermal management.

- If components are configured accurately reduces signal interference and maintains the quality of the signal. Components that are noise sensitive or have high frequency must be accurately configured to minimize signal crosstalk

- There is effective power distribution on the board for required power delivery to components. Connect power-based components such as voltage regulators, capacitors, and decoupling capacitors near power input reduces power noise and voltage fluctuations.

- The component that produces heat must be accurately positioned to have airflow and be close to the heat sink. Ensuring the proper distance between heat-sensitive components helps avoid thermal issues.

- Components must be directed correctly on the polarity bases and pin configuration to fulfill needs. It has accurate connections and compatibility with components during assembly

- Must have proper routing to decrease signal interference and impedance mismatches. The layout must consider short direct traces for high-speed signals and reduce cross path

- Proper clearance must be used between components for high voltage or heat dissipation especially. The component should be placed to help for effective inspection soldering and testing process

How to Choose the Right PCB Components

- Define the function of the circuit and find components according to that. Must consider the input, and output signal processing and certain features need

- Study the features of the component Mentioned on the datasheet. Check parameters like voltage rating, current rating, temperature, and other parameters according to the circuit need

- Choose components from any famous supplier that has more quality components than others. Since proper components selected will help to have a long-term operation

- Choose the component according to the space on your board that can easily fit components. Must check the dimensions of components like pin space, packaging type, and compatibility with the board

- Must check teh power required to circuit then know that component used has the ability to carry that power.

- Environmental conditions must also known since the selected component has the ability to work in those conditions.

- Components must be easily available and have affordable costs since high-cost components make circuits costly.

- Selected components must be compatible with the other devices connected to the circuit.

- Before using the component on board must read its guides and related details

How to Solder PCB Components

Learn How PCB Circuit Board Soldering Guide for Beginners

- First of all, make sure the working areas are clean and do not have any dust particles. The soldering mat can be used for protection of the working area

- Tinnin of the soldering iron is coating the tip with a layer of solder, IT will help the solder flow. For this process soldering irons touch the tip of a small part of the solder

- For component lead heating use a soldering iron and solder pad on board. The lead and pad should be heated to melt the solder

- If lead and pad are hot use a small solder to the joint. The solder should flow over lead and pad

- If solder comes with free movement remove the soldering iron. Joint should be shin and smooth

- Check teh joint to make sure it is free of any bubbles. OF joint is not good we can resolder it

Can the PCB Components Age?

Yes PCB board componet can be ae.

Some main reasons for PCB component aging include:

- Oxidation: it is a chemical reaction that exists when oxygen mixes with another component. In this condition board components get corroded causing conduction and damage

- Cracking: it exits due to vibration excessive heat, and moisture. Cracks affect teh component and cause damage,

- Degradation: The Material of board components can be degraded with time, which can reduce the board operation

Final Thought

Anyone working in electronics must have an understanding of the PCB board. We can easily repair and replace the components if we have proper knowledge of board components whether they are active or passive. Hen handling circuits note that to use accurate tools and follow instruction