Hi students welcome to the new post. In this post, we will Learn How PCB Circuit Board Soldering Guide for Beginners. PCB circuit board soldering is a technique used in electricity to make connections between components. Anyone making projects or preparing devices must know about solder. In this post, we will discuss the detailed process of PCB circuit board soldering, from the basics to troubleshooting common problems. So let’s get started with Introduction to Circuit Board Soldering

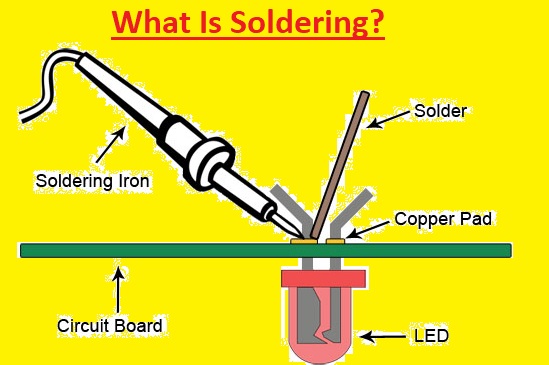

What Is Soldering?

The soldering process involves the joining of two or more electronic components with each other through melting solder over the connection. Solder is a metallic alloy and when it cools it makes strong electrical connections between different components. The soldering process makes permanent connections but it can become weak with the use of desoldering tools

Tools for PCB Soldering

Soldering Iron

The soldering iron is a hand tool that is connected to a standard 120v AC outlet and heated to melt solder over electrical connections. it is an important tool used for soldering and can have some different types like pen or gun form.

it is suggested to use a pen-style soldering iron for beginners in the 15W to 30 Watt range. Most soldering irons come with interchangeable tips that are used for different soldering projects.

Try to use properly any soldering iron since it can get heated at about 896′ F

Solder Wire

For electronics projects comonly used solder wire is made with the use of 40 percent lead and 60 percent tin and when get cools it has a melting temperature of 190 degress.

This alloy comes in wire form in different sizes and it is better to use this gauge than a thick gauge. For normal uses solder wire in the gauge of 18 is best

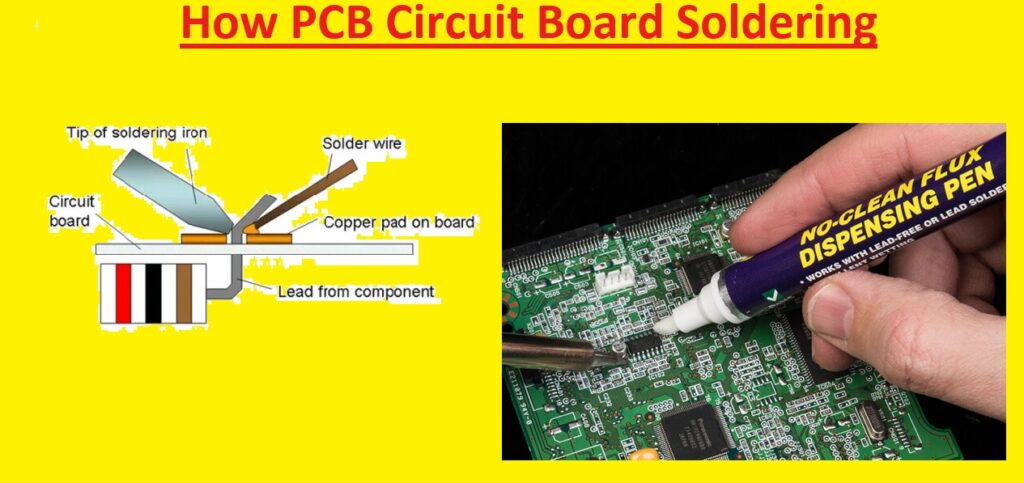

Solder Flux

Solder flux is an important tool used to clean the metal surface joints before and after soldering, reducing oxidation. The flux provides the wetting and soldering process removes oxides over the metallic joint surface and avoids the creation of solder balls.

some types of solder flux are

- Organic acid flux: When soldering metal contacts, acid-based flux ensures that oxides are removed. Since flux dissolved in water, remnants should cleaned after the soldering process to avoid corrosion.

- Alcohol-based no-clean flux: Solder pastes come with alcohol-based non-clean flux, or they are a mixture with resing. it does not spray as other flu and evaporates fastly when heated.

- Rosin flux: The fluxes are made with solid rising and rosin flux residue does not cause corrosion so used in conditions where removing residual organic flux can be difficult.

Sponge

The sponge helps to keep the soldering iron tip clean by removing the oxidation that is created. Tips with oxidation will become black and not get solder like when new.

use conventional wet sponge that has a short lifespan of time due to expansion and contraction. With that wet sponge will lose the temperature time when wiped. The best to use a brass sponge.

Soldering Iron Stand

The soldering iron stand is used to prevent the hot iron tip from making contact with flammable materials or resulting in any injury. Some soldering station has built-in and come with sponges for cleaning tip

Solder Paste

Solder paste has a gray color and it is used to connect different components that need to be configured on board

What Are the Different Types of Soldering Techniques?

Soft Soldering

Solf soldering is a common type of PCB board connection process. This process comes with soldering of temperature about 450 °C or 842 °F. Sift soldering is good for the connection of small components on larger boards.

Before melting the component use tin lead alloy for filler metal. it comes with a melting point of larger thatn 400 °C or 752 °F that helps to make strong connections between components and boards.

Hard Soldering

This selling process called brazing connects two differnt components with the use of alloy film like brass. This method is used on metal surfaces and makes a strong connection then sift soldering as the result of the atomic magnetism and diffusion process.

Hard soldering is spreading solder over the holes of components. The holes are then unlocked when face high temperature. it is good to note that carefully clean surfaces before starting to remove all grease traces.

Hard soldering also uses silver soldering, which uses silver alloy as a space-filling metal. This process recreates a small part of board-free running. But it is not reliable for space-filling.

Braze Soldering

Braze soldering comes with both soft and hard soldering for quality purposes and makes stoner connections between board and electrical components like inductors, transistors, and capacitors. High temperature used for components connection on board. During brazing and hard soldering are same process brazing comes with melting the metallic components for their proper configuring. It is the best soldering method for large-scale board manufacturing and generates less heat distortion

Through-Hole Soldering

Through soldering process is replaced with SMT component but it is still used in many applications SMT is used for compact hardware and has lower cost projects but small manufacturers also use through-hole soldering techniques. As compared to SMT components Through-hole components are strong and practical. In a result, through-hole components are preferred for aviation uses that need strong connections in extreme conditions. .

Step-by-Step Guide to PCB Circuit Board Soldering

Steps to Soldering a PCB

Follow these steps for PCB soldering.

Soldering Iron Preparation

First of prepare the soldering iron for PCB soldering. started with thinning, that is coating tip of iron in solder. helps iron to heat before covering the complete tip with the use of solder. When gets coated clean extra flux and since it can become hard.

Read the Surface

Now ready the board surface. The board must be clean and not have any dust particles or greases. Use an industrial cleaning pad and clear off any particular

Connect Components

First start with small components then move to large components. it helps the board to balance and properly distribute components on board.the best option is to connect components on the lower side that do not have components. Choose some small components and put them over the board. After putting holes bend their leads to 45 degrees which helps components to get their position.

Apply Heat

Use heat heat-resistant pad for PCB soldering to set board position. use a small solder on tip and set the iron so the touch board and lead. The solder will connect both of them, heating the soldering. Hold the iron for a few seconds before using it. For a longer time stay can become iron very hot.

Solder to Joint

When heated touch tip of solder with the solder pad and lead. In this point solder must flow smoothly and the flux starts to become liquid. Continue to add solder over the joint to make a small mound. Now remove the soldering iron and place it.

For smooth finishing make sure the joints are cooled properly

Read also:

- Matte vs Glossy in PCBs

- Lead vs. Lead-Free Solder in PCB Manufacturing – 2023 Ultimate Guide

- What is PCB Leds Circuit Board: What Do You Need to Know

- Thick Film Ceramic PCB

- What is a Cold Solder Joint and How Can You Prevent it?

- Learn How PCB Circuit Board Soldering Guide for Beginners

FAQs

- How do I learn basic soldering?

- Confirm that the soldering iron is completely heated and touch tip to end of wires. Hold it on the wire for three to four seconds. Keep the iron in position and touch the solder to the wire until it is coated. Repeat this proces on other wire and it helps to get bases of soldering

- What are the 5 soldering steps?

- Step 1 – Melting the Solder

- Step 2 – Components cleaning

- Step 3 – Placement of the PCB.

- Step 4 – Solder applications

- Step 5 – Cleaning.

- Which components to solder first?

- First of all solder small components such as jumper leads, diode resistors, and any other small parts then move to the larger compone of the circuit such as the transistor capacitor

- What type of solder is used in PCBs?

lead-free rosin core soldering is commonly used for PCBs

- Which solder is best for PCBs?

- As compared to lead soldering lead free always well for electrical PCB board uses. Lead-free solder does not spread during reflowing. it makes strong bonds without any issues like rapid stencil wear.

- What is the best thickness of solder for PCBs?

The solder resist thickness is about 0.8 mils. Solder masks are thin close to the edges of traces and can be as thin as 0.3 mils or less.

- What size solder is best for PCBs?

- The best solder for circuit baord can be solder wire of diameter about 0.711mm. The width of this wire is best for boards

- Why is 60 40 solder used?

60/40 is soft solder used for the soldering of copper and copper alloys and/or ferrous base alloys. It is not used for soldering of potable water systems due to its high lead content.

- What is a good flux?

A good flux can be clean and easy to remove. It must also be non-conductive. and non-corrosive.

normally best soldering flux is rosin-based flux. this flux is not corrosive does not left residue and has less melting point.

- What is a flux used for?

Before soldering, flux is used for cleaning metal surfaces. it increases the chance of a strong connection made by solder. Fluxs help in avoiding oxidation of the metal surfaces.

- What thickness is solder for PCB?

0.015 inches to 0.062 inches