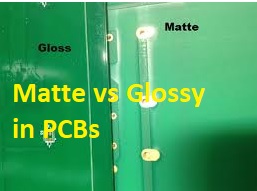

Hello readers, welcome to the new post. Here we will discuss Matte vs Glossy in PCBs. In electronic engineering, for PCB boards, the use of matte and glossy finishes are essential parameters for the operation of electronic devices. In this post, we will discuss the matte and glossy finishes used in the board and their features. So, let’s get started with Matte vs Glossy in PCBs.

Understanding PCB Finishes

PCb finishes work as a protective layer on copper traces and board pads, protecting them from different environmental conditions like wear, tear, and corrosion.

Matte Finish

In the PCB board manufacturing proces, matte finishing is a type of surface finish that makes a dull surface and non-reflective look on the board.

This finish is used in applications where reflectivity of the board surface can result in interference with the working of devices like imaging devices or optical.

This type of finishing is made by applying chemical treatment to the surface of the board after the copper plating process. This process removes any remaining copper oxides and makes a roughened surface that minimizes the reflection of the board.

In a result surface that comes with a flat, non-smooth look is called a “matte” finish.

There are 2 main types of matte finishes used in PCBs:

- Water-based finishes it used on the board and then cured using water. This process is relatively easy and less costly, and it causes a good-quality finish.

- Solvent-based finishes it used on the board and then cured using a solvent. it takes some time to apply, but it makes durable products

Glossy Finish

In the PCB manufacturing process, this type of surface finish generates a reflective and shiny layer on the board. This finish is used in applications where PCB look is important, like in consumer electronic devices.

To get a glossy finish on the board manufacturing metallic layer, like silver, gold, or tin is used on the surface of the board after the completion of copper plating.

The metallic layer is polished to make a smooth and reflective look and provdies a glossy look on board.

WHAT IS A GLOSSY FINISH IN PCBS?

There are two main types of glossy finishes used in boards

- UV-cured finishes: This finish is used on board and then cured using ultraviolet light. This process is high-speed and effective, provdies a quality finish

- Solvent-based finishes it used on board and then cured with the use of solvent. It takes time to apply and casues a durable finish

BENEFITS OF A GLOSS FINISH ON A CIRCUIT BOARD

- It provdies pCB aesthetic and class look. Many engineers and manufacturers give board a glossy finish since a shiny look provdies the board a modern appearance.

- it reduces signs and symbols of wear with its less reflective features.

- It has scratch resistance. The glossy finish offers a harder surface to the board, that is high rate of resistance to scratch then matte finish of PCBs.

ADVANTAGES OF A MATTE FINISH ON A PCB

- It provdies a visible look during the inspection of the board. The matter board finishes do not have a shine or lightning effect, which provides a visible look in the inspection process. So it provdies a clear and visible look at manufacturing and PCBA.

- It offers the easy detection of issues. The matter board finish comes with features to detect errors easily and fastly then a glossy PCB finish. Due to its visible nature, it makes it easy to find errors.

- It minimizes the creation of solder balls. Many manufacturers refer to that board matte finish comes with less risk to make solder balls. The less glossy rate makes lesser formation of solder balls.

WHY CHOOSE A GLOSSY FINISH OVER A MATTE FINISH?

The basic difference between a glossy finish and a matte finish is aesthetic and some people think that a gloss finish has a better look.

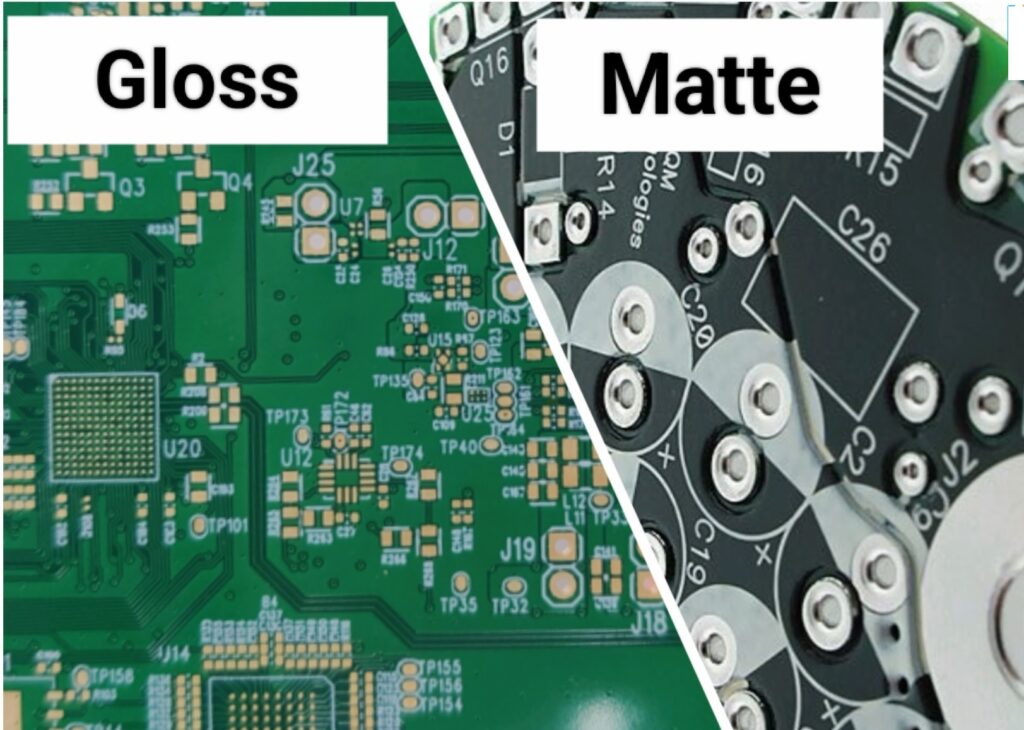

The gloss solder mask is shin. It reflects light and shows a bright appearance, and the matte finish is dull and dark.

The gloss solder mask comes with a hard shell finish and the matte finish is softer.

Matte finish also scratches easily and has surface cosmetics, though scratches on the gloss finish look more

Some main casues for choosing a glossy finish over a matte finish are

For uses where appearance affects board marketing glossy finish can help to increases the look

If there is no certain finish for you note that glossy finish works as the default finish used in industries.

Factors To Estimate When Choosing a PCB Finish

- Surface finish can easily solder, and it must solder to wet and flow correctly. It is best for electrical connection between component and board.

- This finish must be robust to handle the harsh conditions of the manufacturing process.

- it must be less costly for larger production

- if the board is used in lead-free condition surface also lead-free

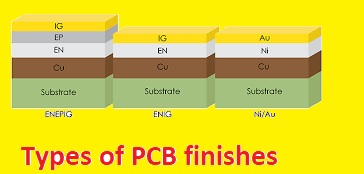

Types of PCB finishes

- HASL (Hot Air Solder Leveling) is a commonly used surface finish. It is less costly and has good soldering featues. But it is not robust and is affected easily.

- ENIG (Electroless Nickel Immersion Gold): It is a price finish but has good solid featues than HASl and is lead-free

- OSP (Organic Solderability Preservative): It is a new finish type growing fast. It is more environmentally friendly than HASL and ENIG since it has good soldering features.

- Tin lead is a legacy surface finish that is not used since it does not follow the different rules of the environment. But till used where lead is involved

Why CHOOSE A MATTE FINISH OVER A GLOSSY FINISH

It is not cost cost-effective solution to choose matter finish over a glossy finish, but solder balls is the main cause. If you are thinking about solder balls that can cause issues you can choose matte finish. So the main reasons are

- For consideration of manufacturing accuracy at top value, a matte finish is the better option for manufacturing. But some expert PCB manufactures must check errors in any finish used.

- If there is need to inspect PCB by yourself after manufacturing, matt finish is best to use. It helps to find error clearly to offer accurate result to board manufacturers.

Glossy vs. Matte Finish

Glossy Finish

- Shiny, reflective Surface

- Colors appear brighter and more vibrant

- Smooth texture

- durable and scratch-resistant

- Reflects light, making the surface appear larger

- Easy to clean and maintain

- Modern, elegant settings

Matte Finish

- Dull, non-reflective look

- Slightly rough texture

- Colors is muted and subdued

- It does not reflect light, making the surface appear smaller

- Less durable and prone to scratches

- difficult to clean and maintain

- Rustic, traditional settings

What is the best finish for PCB?

Electroless Nickel Immersion Gold is very comon and moslty used board finishes. It made with two coating layers ENIG places 2-4 μ” Au over 120-200 μ” Ni.

Read Also:

- What is Ball Grid Array (BGA) on a PCB Board

- Difference between Double sided and Multilayer PCB Board

- Double Sided PCB Board, Construction, Working, Types & Applications

- What is PCB (Printed Circuit Board), Types, Working, Features & Applications

- PCB Heat Dissipation Techniques

faqs

- Which is better matte finish or glossy?

A glossy finish has an ultra-smooth shiny look. Its color is vibrant. While matte papers give off a dull, subtle finish.

- What is the difference between matte and gloss solder masks?

A matte solder mask is a dull, non-reflective finish used on the top of a printed circuit board. Protects copper traces on board from corrosion and oxidation and it helps to easy soldering of components.

The gloss solder mask has a shin look, and reflective finish that is used on the board and comes with an attractive look but it is not as effective for the protection of traces as the matte finish.

- What is the difference between a matte and shiny surface?

A matte surface does not reflect light good. It comes with a dull, non-reflective finish. The shiny surface has good light reflection and also glossy and reflective finish

- Which is better matte or glossy bike?

Matte bikes are less reflective and can handle more scratches and dents. Glossy bikes are reflective and can make the bike look more stylish.

-

What are the advantages of a matte finish?

- Less reflective, affected by fingerprints

- Les imperfections

- Rustic look

- Durable and resistant to scratches

-

What are the advantages of a glossy finish?

- High reflective, vibrant, and bright look

- Easy to clean

-

What are the disadvantages of gloss paint?

-

More reflective and likely to affect fingerprints and smudges.

-

Its application is difficult

-

Expensive than matte paint.

-

Is glossy more expensive than matte?

glossy finishes are more expensive than matte finishes. The glossy finish needed more paint coating, and it also needed certain paint, which is highly reflective

- What is the top mask of a PCB?

it is a layer of material that is used over the board’s top layer for the protection of traces and provdies surface to use a solder mask and silkscreen printing. It is made with material like epoxy or acrylic.

- What is top solder layer in PCB?

It is used for the connection of components on board. The solder layer is made with materials like tin or lead.

- What are layers in PCB?

A PCB board is made with many layers of materials like copper, substrate, and solder masks. The number of layers in a board is based on the board’s complexity. A simple board can only have some layers, while a complex board comes with many layers.

- What is matte vs glossy advantages and disadvantages?

| Finish | Advantages | Disadvantages |

|---|---|---|

| Matte | Less reflective, durable, and resistant to scratches, more forgiving of imperfections, | It can look dull or unfinished and can be difficult to clean |

| Glossy | high reflective, makes colors bright and vibrant, can look more modern or sleek | likely to have fingerprints and smudges, difficult to apply evenly, high cost |

What is the difference between glossy and matte finish on metal?

-

Property Description Reflection Susceptibility Application Glossy Smooth and shiny Reflects light susceptible to fingerprints and scratches Good for highlighting details Matte Dull and has a rough texture Absorbs light resistant to fingerprints and scratches Good for making a subtler look

What is the difference between matte and polished metal?

-

Property Polished metal Matte metal Surface Smooth, shiny Rough, dull Reflectivity High Low Susceptibility to scratches High Low Suitability for highlighting details Good Poor Suitability for creating a subtle look Poor Good

What are the disadvantages of matte finish?

- It is difficult to clean

- Affected due to fingerprints

- Less vibrant

- Less reflective

What are the disadvantages of matte paint?

- Not easy to apply

- It is difficult to touch up

- Fading and chalking

- Less reflective

What type of finish is matte?

- it is a finish that has less shine

- These finishes are used on metal, wood, and plastic

- Differnt techniques used for this are sanding, painting, and powder coating.

What is glossy used for?

- its main feature is shine

- it is used on automotive parts, furniture

- polishing, painting, and clear coating used to apply it

Why use glossy paint?

- For shiny, reflective surface.

- Make color vibrant

- and easy to clean.

- More durable than matte paint.

What is glossy paint used for?

- Glossy paint is used for different applications and are

- Furniture

- Appliances

- Automotive parts

- Toys

- Sports equipment

- Exterior walls

- Interior walls

- Cabinets

- Countertops

What are the pros and cons of matte paint?

-

Pros Cons Easy to clean Not shiny as glossy paint resistant to fading and chalking difficult to apply Can hide imperfections on the surface accepted by fingerprints and smudges

Why is gloss paint more durable?

- Harder, protective finish than matte

- Resistant to scratches, fading

Is gloss paint moisture resistant?

- Yes, gloss paint is high moisture-resistant than matte paint. its glossy finish makes a layer that avoids moisture to the surface

What is 2 layers in PCB?

- It comes with two conductive layer

- Insulting material is put between conductive layers

- and two-layer boards used in low-complexity applications.

What are the three layers of PCB?

- it has three conductive layers

- Tow insulation materials separate layers

- Used in medium-complexity applications.

What is dry joint in PCB?

- it is the connection between two conductive pads on board that not have solder

- Dry joints come due to poor quality components, incorrect soldering methods, or environmental conditions.

Is matte cheaper than glossy?

- Matte paint is less costly than glossy paint.

- As matte paint needed less material and labor to apply.

Which is better semi-gloss or matte?

-

Semi-gloss

- Pros:

- Easy to clean

- Durable

- Cover error on the surface

- Cons:

- reflective than needed

- difficult to apply than a matte

Matte

- Pros:

- Not reflective like semi-gloss

- Easy to apply

- resistant to fading and chalking

- Cons:

- Difficult to clean than semi-gloss

- Affected by fingerprints and smudges

- Pros: