Electronics is a field that is always evolving, with new technologies appearing all the time. Electronic components and assemblies are the backbone of modern living, found in everything from smartphones and smart appliances to medical equipment and car electronics.

Behind these cutting-edge technologies lies a crucial industry known as Electronic Manufacturing Service (EMS) or Electronics Contract Manufacturing (ECM).

In this comprehensive article, we will delve into the realm of EMS, exploring its role in designing, manufacturing, testing, distributing, and providing return/repair services for electronic components and assemblies. Additionally, we will take a closer look at a vital segment within EMS known as Box Build Assembly, where PCB assembly and enclosure assembly come together to create products ready for use by consumers and industries alike.

Understanding Electronic Manufacturing Services (EMS)

Defining EMS

EMS refers to a group of services provided by companies that specialize in the manufacture and assembly of electrical parts, including circuit board, PCB assembly, complete electronics assembly and testing. These services can be accessed by original equipment manufacturers (OEMs) to undertake different assignments like industrial devices, consumer electronics, test and measurement, telecommunications, new energy, medical and healthcare, automotive, etc.

EMS providers are critical in translating innovative ideas into practical electronic units, propelling society into a modern era.

The Scope of EMS

The scope of EMS is wide-ranging and encompasses multiple stages of the electronic product lifecycle:

- Design

During the design phase, the EMS providers work closely with OEMs. They provide information on the aspects of component choice, ability to manufacture, and affordability. With the help of their expertise, the EMS companies are in a position to make the designs efficient and more productive.

- Manufacturing

The basic task in EMS has been and will always remain manufactured, which is the most important point. This involves manufacturing such things as electronic components, PCBs, and complex assemblies. The third phase requires accuracy as it will involve using modern machines and equipment.

-

Testing and Quality Assurance

Stringent testing and quality assurance procedures are integral to Electronic Manufacturing Service operations. Components and assemblies undergo rigorous testing to identify defects, ensure compliance with industry standards, and meet OEM specifications.

-

Distribution

Once manufactured and tested, electronic components and assemblies are distributed to OEMs. This stage involves logistics, supply chain management, and coordination to ensure timely delivery.

-

Return and Repair Services

EMS providers often offer post-sales support, including return and repair services. This helps OEMs address issues with products already in the market, enhancing customer satisfaction and brand reputation.

The Role of Electronics Contract Manufacturing (ECM)

While EMS is the widely accepted term, it is worth noting that some industry professionals refer to these services as Electronics Contract Manufacturing (ECM). ECM essentially refers to the contractual nature of the relationship between EMS providers and OEMs.

At this condition, EMS companies take on the responsibility of manufacturing electronic products on behalf of the OEMs, offering a seamless and efficient production and outsourcing solution.

Box Build Assembly: Merging PCB Assembly and Enclosure Assembly

Within the vast landscape of EMS, one specialized area plays a critical role in delivering end-user products directly to consumers and industries: Box Build Assembly.

Defining Box Build Assembly

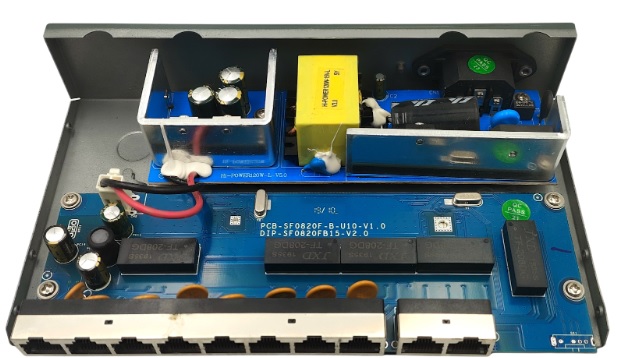

Box Build Assembly is a distinct segment of EMS that combines two crucial processes: PCB assembly and enclosure assembly. This integrated approach results in fully functional electronic products that can be used directly by customers. The term “box build” is derived from the practice of assembling all the necessary components, including the PCB, into a complete enclosure or housing, often resembling a box or casing.

The PCB Assembly Process

- PCB production and electronic parts sourcing: Firstly, we need to produce or outsource printed circuit boards, and they buy all the necessary components as the BOM (bill of materials).

- Part Position: The PCB assembly process starts with the cautious arrangement of electronic parts onto the PCB. This step requires accuracy and automation to guarantee exact positioning.

- Usually, both manual and automatic pick and place equipment are needed in PTH and SMT assembly.

- Soldering: Whenever parts are placed, soldering methods are utilized to get them in place. Surface-mount technology (SMT) and through-hole technology (THT) are commonly used techniques.

- Quality Examination: In addition, extensive quality checks are made to identify irregularities or poor soldering. Precision in detecting defects has been made possible through the use of high-level automated inspection systems.

- Testing: Functional testing is used to confirm the performance of the assembled PCBs. Immediate responses go for any deviations from normal operations.

- Visual inspections: Visual inspections are always needed to catch the defects which can not be detected by equipment.

The Enclosure Assembly Process

- Housing Selection: It is selected on account of the product’s design specifications and constitutes a fenced area or housing. Aspects such as size, material, and nature significantly influence the choice of this design element.

- Integration: The selected enclosure is accurately synchronized with all its constituent parts like PCB, wiring, connectors, etc.

- Final Assembly: There will be a move of all parts in the fenced-in area, with the installation of displays, buttons, power supply and connections for them at the final assembly stage.

- Testing and Quality Assurance: Enclosure assemblies undergo rigorous tests and quality controls like that for PCB assembly to meet specified standards.

Advantages of Box Build Assembly

Box Build Assembly offers several advantages:

- Streamlined Production: By consolidating PCB assembly and enclosure assembly, the production cycle turns out to be more proficient and cost-effective.

- Reduced Lead Times: OEMs can profit from shorter lead times as the whole item is collected and tried in one location.

- Quality Control: Centralized quality control guarantees that the result satisfies top-notch standards.

- Time-to-Market: Box Build Assembly speeds up time-to-market for new electronic items, permitting manufacturers to respond rapidly to market demands.

Applications of Box Build Assembly

- Box Build Assembly is employed in various industries, including but not limited to:

- Industrial Equipment: Machinery and control systems depend on box build assembly for proficient integration of electronic parts.

- Medical Devices: Essential clinical gear, like patient screens and diagnostic gadgets, use box build assembly to guarantee accuracy and reliability.

- Automotive: In the automotive sector, box build assembly is fundamental for infotainment systems, navigation units, and control panels.

- Consumer Electronics: LED and lighting, Cell phones, tablets, and home appliances frequently go through box build assembly to guarantee consistent integration and functionality.

Conclusion

Electronic Manufacturing Service (EMS) and its particular fragment, Box Build Assembly, play essential parts in forming the advanced electronic industry. EMS suppliers, whether referred to as EMS or Electronics Contract Manufacturing (ECM), offer far-reaching arrangements that envelop configuration, production, testing, distribution, and post-sales support.

Box Build Assembly, on the other hand, overcomes any barrier between PCB assembly and enclosure assembly, bringing about completely utilitarian electronic items prepared for use. In a period characterized by mechanical development, EMS and Box Build Assembly act as the foundation of an industry that keeps on pushing the limits of what is possible in electronics.