Hello readers welcome to the new post. In this post, we will have a look at What is Autotransformer Starter. Autotransformers are considered as important to controlling the function of electrical motors. These starts provide effective and less costly solutions for starting and controlling the speed of the motor. In this post, we will learn the working principle, advantages, and other parameters of auto transformer starters. Let’s get started with What is Autotransformer Starter

Introduction Auto Transformer Starter

An autotransformer starter is an electrical transformer that comes with a single winding. The AUTo means single coin working alone. In this transformer part of the same winding work as both primary and secondary windings.

In conventional transformers, separate primary and secondary winding are connected through the electrically conductive path.

The autotransformer winding comes with three electrical connections with winding. As part of winding performs double duty autotransformer winding comes with the benefit of small size, less weight, and less cost as compared to the dual winding transformer.

Its disadvantage is that electrical isolation between primary and secondary circuits exits. But comes with less leakage reactance, fewer losses low excitation current, and a high VA rating of size and mass.

The common application of autotransformer is style of traveler voltage converter that helps 230-volt devices to be used on 120-volt supply circuits.

The autotransformer comes with many taps for adjusting the voltage at the end of the long distribution for accurate excess voltage loss that is used on the voltage regulator.

Working Principle of Auto Transformer Starter

An autotransformer starter with less voltage start reduces the voltage provided to the motor during the starting process. It reduces starting current and torque offers motor protection and system

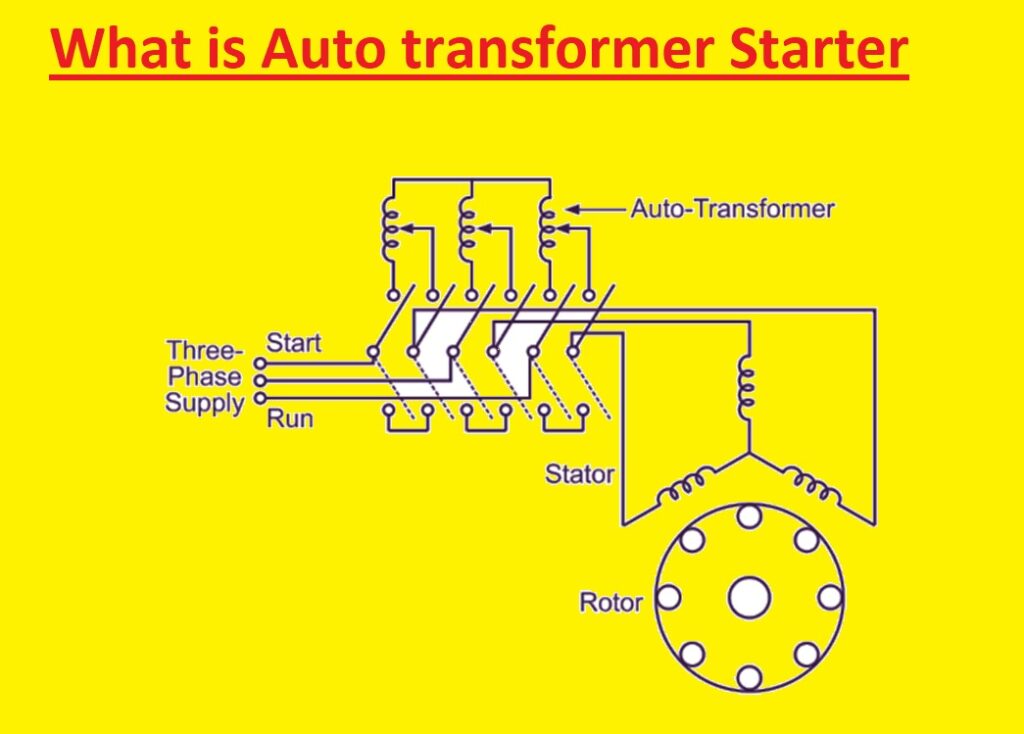

Construction of Auto Transformer Starter

The autotransformer starter has these components listed here

- Autotransformer

- Contactor

- Start/stop button

- Fuse

- Overload relay

Different Types of Induction Motor and Features

It is a single-phase or three-phase transformer that has taps in secondary windings. A contactor is an electrical switch used for the connection of a motor with the power source. The start/stop button manual switch is used for motor start and stop. Fuses provdies protection to the motor from loads. Overload relay offers protection to the motor from overloads

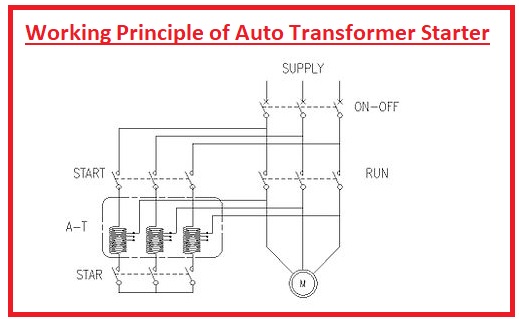

Auto Transformer Starter Working Principle

The autotransformer starter working operation is explained here

- After pushing the start button contact closes and the motor makes a connection with the power source through the autotransformer

- his transformer reduces voltage connected with the motor reduces starting current and toque.

- The motor starts operating slowly

- After getting the operating speed by motor contacts open and motor now has a direct connection with the power source.

- After pressing the stop button contacts get open and separate the motor from the source

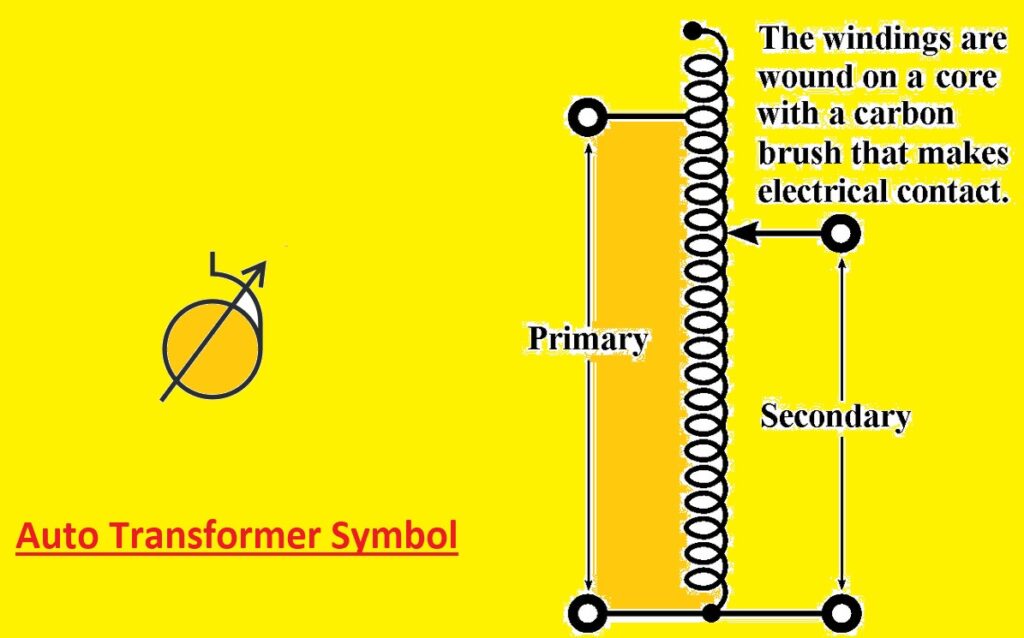

Auto Transformer Symbol

The symbol of autotransformer has a triangle with a circle at the midpoint. Traigle shows the primary winding of the transformer and the circle used for the secondary winding. The size of the circle has a proportional relation with voltage decrement which is the output of the autotransformer

diagram of an autotransformer symbol can be seen above

This diagram has primary winding on the left side and secondary winding on the right side. The circle at mid shows the tap used to choose the required voltage value to decrease

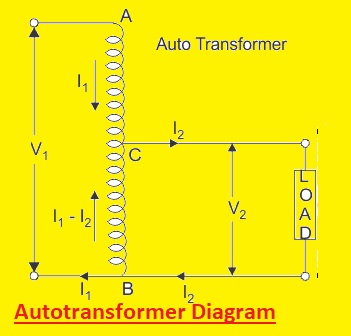

Autotransformer Diagram

- The autotransformer diagram can be seen here

Advantages and Disadvantages of Auto Transformer Starter

Advantages

- For the transformation ratio is two, the size of the auto transformer is about fifty percent of a 2 winding transformer. According to transformation ratio 2 , the size will be 95 percent.

- The auto transformer comes with high efficiency as compared to two winding transformers. Since less ohmic loss and core loss due to reduction of transformer material.

- The autotransformer is less costly and small in size.

- it has good voltage regulation since voltage loss in resistance and reactance of single winding is less.

Disadvantages of Auto Transformer

- Due to the electrical conductivity of primary and secondary winding lower voltage circuit is a chance to be affected due to high voltage. For avoiding lower voltage circuits it becomes necessary to make low voltage circuits for handling high voltage.

- The leakage flux between primary and secondary windings is small and has less impedance. It casues short circuit currents during fault conditions.

- Connections on the primary and secondary sides needed to be the same except using interconnection starring connections. It causes complications due to varying primary and secondary phase angles, especially in delta connections.

- Due to common neutrality in star or star-connected autotransformers, there is no chance of Earth neutral on a single side. Both sides must be neutral either isolated or earth.

- It is not easy to maintain the electromagnetic balance of winding when voltage adjustment tapping is connected. it must be known that the provision of tapping on the auto transformer increases transformer frame size.

Applications of Auto Transformer Starter

- It adjusts in resistance type heater.

- It is part of cutting styrofoam

- It used for speed control of the fan

- It adjusts AC power supply

- Helps the line voltage compensation

- It regulates DC power supply of high-current

Auto Transformer Starter Comparison with Other Starter Types

| Starter Type | Auto Transformer Starter | Direct-On-Line Starter | Star-Delta Starter |

|---|---|---|---|

| Principle of Operation | It uses an autotransformer to regulate voltage during the starting process | Supplies full voltage directly to the motor | Starts the motor with less voltage, then switches to full voltage |

| Voltage Regulation | smooth and controlled voltage regulation during the starting process | No voltage regulation, casues high current surges | less voltage during startup then switches to full voltage |

| Energy Efficiency | voltage losses energy-efficient process | Less energy-efficient due to high starting current surge | Less energy-efficient than autotransformer starters |

| Motor Protection | Connected to protective devices like overload relays and fuses | Limited motor protection, | Limited motor protection, needed some protective devices |

| Applications | used in industrial, commercial, and residential applications | small motors and applications where cost is a factor | best for motors with high inertia and torque |

| Cost-effectiveness | cost-effective than other starter types | Economical solution for small motors | costly due to additional components |

| Voltage Range | Limited voltage adjustment range | Full voltage supply | Limited voltage adjustment range |

| Harmonic Distortion | casues harmonic currents if not properly addressed | less harmonic distortion | less harmonic distortion |

| Inrush Current | The moderate inrush current | The high inrush current | The moderate inrush current starting process |

Theory of Autotransformer Starter

The theory behind an autotransformer starter is based on the working of an autotransformer. it is a transformer that comes with a single winding with many taps. it operated by sharing some part of winding between input and output that is used for voltage transformation and changing volt value

In autotransformer starter, the autotransformer is used to reduce the voltage of the motor in the starting. Fewer volts restrict inrush current which is a high current at the motor starting

This device has an autotransformer, contacts, and a control circuit. Control circuit used for starting and control motor working autotransformer starter. In the starting process controls, the circuit energizes the autotransformer through closing contacts. it makes a motor connection with low volts that increases the connection of the transformer to shift towards different taps. The slow increase in volts limits inrush current and avid any damage ot the motor and system. When the motor gets full speed autotransformer starter is removed and the motor comes with a direction connection to voltage.

Limitations of Auto Transformer Starter

Although auto transformer starters also have some limitations

- it is not used where different values of volt adjustment are used.it is effective in moderate voltage needs

- it causes harmonic currents into the electrical system, which casues power issues

- Starting volts casues high inrush currents, which can affect the stability of the power supply or affect other devices connected to the same system.

What is the purpose of the starting transformer?

What is the full form of ATS starter?

What is the working principle of transformers?

How transformer works step by step?

What are the three main components of a transformer?

- an iron core which

- primary winding

- secondary winding

What is the function of ATS panel?

Do transformers work on AC or DC?

What are the main parts of the transformer?

- How to Replace Doorbell Transformer With Diagrams

- How to Connect Doorbell Transformer Wiring Diagram

- All Types of Electrical Transformer Symbols and Diagram

- Difference Between Current Transformer (CT) & Potential Transformer (PT)

- Introduction to Ideal Transformer, Working, Phasor Diagram, & Circuit

- Transformer Taps and Voltage Regulation

FAQs

What is the auto transformer starter?

An autotransformer starter is a motor starter that operates on an autotransformer to minimize voltage given to the motor in the starting process. It decreases the current of the motor.

What is auto transformer and its working?

An autotransformer is a transformer type that comes with one winding. The winding is tapped at 2 different points, which helps the voltage to increase or decrease

The autotransformer starter operated by connecting the motor to the lower-voltage tap of the autotransformer.

What is the difference between VFD and auto transformer starter?

A variable frequency drive is a motor controller which varies the frequency of voltage to the motor. It helps the motor operate on different speeds which is good where the motor needs to operate at different speed values.

An autotransformer starter is a simpler module than a VFD. It is also less costly, but it does not provide the same level of flexible operation

What is a starting transformer?

A starting transformer is employed for reducing string volts. It reduces the curent of the motor and saves it from any damage

Starting transformers are normally used with large motors, like in industrial applications.

Why use an autotransformer starter?

its main uses are limiting inrush current, decreasing excitation current, varying starting volts, and good voltage regulation

Where is the autotransformer starter used?

Autotransformer starters used in industries for larger-size motor control. also used in commercial and residential applications.

What are the two types of autotransformers?

There are two main types of autotransformers:

- Tap-changer autotransformers: it has different taps that are used for various motor volts

- Stepless autotransformers: These autotransformers provdies continuously variable voltage output.

Which starter is mostly used?

Since they are less cost and easily connected and use

What are the common uses for an autotransformer?

Autotransformers are used for differnt uses that are

- Reducing the voltage applied to a motor during startup

- Providing a variable voltage output

- Converting between two different voltages

- Isolating two electrical circuits