Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at Rigid Flex PCB. The PCB is an acronym of a printed circuit board, this board is used almost in each and every electronic circuitry and device like computers, GPS (Global Positioning System), mobile phones, etc. On this many conductive tracks are designed by the copper layer for assembly of different circuits. There are numerous types of PCB according to construction and uses like single sided PCB, double-sided PCB, rigid PCB, aluminum PCB, flex PCB, etc. In today’s post, we will explain its types called rigid-flex PCB (printed circuit board).

Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at Rigid Flex PCB. The PCB is an acronym of a printed circuit board, this board is used almost in each and every electronic circuitry and device like computers, GPS (Global Positioning System), mobile phones, etc. On this many conductive tracks are designed by the copper layer for assembly of different circuits. There are numerous types of PCB according to construction and uses like single sided PCB, double-sided PCB, rigid PCB, aluminum PCB, flex PCB, etc. In today’s post, we will explain its types called rigid-flex PCB (printed circuit board).

This category of printed circuit board is a combination of both rigid and flexible printed circuit boards. This board has features of rigidity and flexibility that exist in flexible and rigid circuit boards separately. In today’s post will have a look at its working, construction, advantages, practical uses, and some other related parameters. So let’s get started with Rigid-Flex PCB.

Rigid Flex PCB

- Rigid-Flex PCB is being manufactured by the combination of rigid and flexible printed circuit boards. This circuit board usually comprises of many layers of flexible substrate substance and one or more than one board of rigid PCB.

- The designing of this board is a little bit difficult compared to a rigid circuit board because this module is designed according to a three-dimensional environment that also provides high spatial efficiency.

- The main benefit of this board is that it provides highly flexible, decreases flex thickness and less expensive circuit board.

- As on the traditional printed circuit board we can assemble a large no of components on any side of a rigid circuit board. Since the incorporation that exits among rigid and flex circuitry, a rigid-flex assembly does not use connectors among the units. In its place, the flex circuitry electrically joins the scheme together.

- The absence of connectors provides some benefits that are mentioned here.

-

- It increases the capability of circuitry to send a signal with less distortion.

- Houses precise impedance value.

- It reduces joining issues like cold connections.

- It also decreases the weight of the board.

- Each rigid-flex printed circuit board is divided into different parts that have different categories of layers and quantity.

- The number of layers can be larger than the flexible portion and construction substance can be FR4 (Flame Retardant) or polyimide.

Features of Rigid-Flex PCB

- These are some features of a rigid-flex printed circuit board that are mentioned here in detailed.

| Feature | Parameters |

| Quality Grade | It follows the IPC 2 protocol. |

| quantity of Layers | This board can have two to twenty-four no of layers. |

| Quantity for orders | One piece to one thousand plus pieces you can orders. |

| creation Time | It takes two to five days for creation. |

| Material | DuPont (PI25UM), FR4 (flame resistant) |

| Board Dimensions | Its minimum dimensions are six milimeter x six millimeter and maximum are 457 milimeters x 610 millimeters. |

| Board Thickness | The thickness of this board is 0.6 millimeters to five millimeters. |

| Copper Weight | Copper weight is from 0.5 ounces to 2.0 ounces. |

| Minimum Tracing | Three mil. |

| Solder Mask Sides | According to file. |

| Solder Mask Color | Its color can be green blue, white yellow, black. |

| Silkscreen Sides | According to the file. |

| Silkscreen Color | Its color can be white, black, and yellow. |

| Surface Finish | HASL(Hot air solder leveling) Lead – free HASL – RoHS (Restriction of Hazardous Substances) ENIG – RoHS |

| Min Annular Ring | Four-mil. |

| Min Drilling Hole Diameter | Eight-mil. |

| Impedance control | ±10 percent. |

Advantage of Rigid Flex PCB

- These are some benefits of this circuit board.

- This circuitry board permits you to purchase and construct a board according to your device’s requirements.

- This PCB is not heavy and has less size.

- This module can be very easily adapt to any working environment due to this feature it can easily twist and use other circuitry.

- Absence of soldering connection from this board increases its reliability for different projects.

- It provides less damage to circuitries.

- This PCB board also bears higher temperatures as in its construction polyamide is used that helps to bear temperature. Due to temperature bear capability, it used in different medical devices.

- For the production of this board we not need to purchase large no of material so this makes it cost-effective.

- This board also has the ability to affect ultraviolet radiation and also resist oils and severe chemicals.

- The structure of this board is such that we can make circuits on any side of the board.

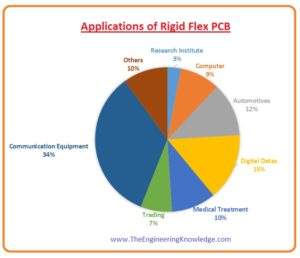

Applications of Rigid-Flex PCB

- These are some applications of this PCB board.

- This circuit board is used for numerous engineering projects for simple designing to complicated structures like the aviation system, military instruments, and mobile phones.

- Due to not heavyweight it used in medical devices like pacemakers.

Points to consider to Buy Rigid-Flex PCB

- Before buying this circuit board you must consider some points that are described here.

- This PCB provides many specifications due to this it best option for much industrial application.

- So it is significant that before selection this board follows the requirements of your circuitry.

- For less weight and place this PCB is the best option for your projects.

- If you are a regular project maker always try to buy groups of circuit boards that will make cost-effective.

Related Posts

- Aluminum PCB (Printed Circuit Board)

- Multilayer PCB (Printed Circuit Board)

- Rigid PCB (Printed Circuit Board)

- Flex PCB (Printed Circuit Board)

- High Frequency PCB (Printed Circuit Board)

- Single Sided PCB (Printed Circuit Board)

- Rigid-Flex PCB (Printed Circuit Board)

- Double sided PCB (Printed Circuit Board)

This the complete post on the Rigid Flex PCB if you have any queries about it ask in comments. see you in the next tutorial. Have a good day.

What i do not realize is actually how you are not really much more well-liked than you might be right now. You are very intelligent. You realize thus significantly relating to this subject, made me personally consider it from numerous varied angles. Its like men and women aren’t fascinated unless it’s one thing to accomplish with Lady gaga! Your own stuffs outstanding. Always maintain it up!

Amazin!

This is a great blog.

Very nice post. I just stumbled upon your blog and wanted to say that I have truly enjoyed browsing your blog posts. In any case I’ll be subscribing to your rss feed and I hope you write again very soon!