Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, I am going to explain a Rigid PCB. PCB is a circuit board that uses in different engineering projects and electronic devices for circuit production, it stands for the printed circuit board. There are numerous types of this circuitry board, like single-sided, double side, flex PCB, multilayer PCB.

Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, I am going to explain a Rigid PCB. PCB is a circuit board that uses in different engineering projects and electronic devices for circuit production, it stands for the printed circuit board. There are numerous types of this circuitry board, like single-sided, double side, flex PCB, multilayer PCB.

In today’s post, we will have a look at a rigid printed circuit board. This category of a circuit board has very less or no flexibility in its structure as we already know that PCB exists in a single side and double side layout similarly rigid PCB is also available in single-sided and double-sided design. So let’s get started with a rigid PCB.

Rigid PCB

- The rigid printed circuit board is not easy to reshape and bend due to hard and solid structure.

- After its construction, it can reshape its design and during its construction its shape designed properly after that it shape cannot be varied.

- For its hard and inflexibility during its construction, a stiffener FR4 (FR stands for flame retardant) is used that increases its rigidity.

- The substrate of this board is hard and has high rigidity on this board there are numerous paths of copper are designed for the connection of different components.

- The best example of this type of printed circuit board is motherboard of your personal computer constructed by the rigid PCB.

- If you compare the price of a rigid circuit board and flexible board than the price of the rigid board is less. It is the conventional category of printed circuit boards that mostly used in numerous electronic devices.

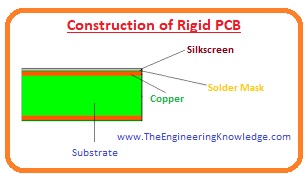

Construction of Rigid PCB

- There are some parts of this PCB that are assembled during its construction by making a specific shape. All these parts and layers of this board are described here with detailed.

- There are main four layers exist in the structure of rigid PCB thta are listed here.

- Substrate

- Copper Metallic Layer

- Solder Mask Layer

- Silkscreen layer

- The bottom layer of the rigid layer is the substrate layer over which other layers reside it is created through the use of FR4.

- Above the substrate that is created through FR4 second layer of copper, the material is placed. Copper layer generally employed on both sides according to projects arrangements and configuration over which it used,

- To protect the copper layer there is the third layer of solder mask is placed on it.

- Fourth one and the last one is the silkscreen that used to make a symbolic representation of different components that used to make proejct.

CHARACTERISTICS OF RIGID PCB

- Some features of rigid board are discussed here

- This board like the other boards such as flexible board can not be transformed into other shapes. It consists of FR4 material that increases its hardness

- For making the connection of different components on the boards there are different paths and copper traces designed.

- Rigid material used on the substrate to enhance the rigidity and strength of board.

- PC motherboards are created with this board.

- After the creation of this board cannot be transformed into other shapes.

- Due to less expensive than flexible board it is used in different electronic devices.

DIFFERENCES BETWEEN RIGID PCB AND FLEXIBLE PCB

- In electronic devices normal rigid board is used. But in some projects not used due to its nonflexible nature.

- The flexible nature of a flexible board enhances its use in projects

- The creation process of these boards is like with some differences such s flexibility, prices and rigidity

- There are certain measures needed to handle the flexible board. With that certain features are needed to reduce damage to solder joints in case of board twist

- Expenses of flexible boards are higher than the rigid board. But in case of projects cost of the overall board can be higher with use of the rigid board.

- Different devices such as sound system circuits, PC toys, and other electronic devices are created with a rigid board.

- In high-level devices such as camera, mobile phones GPS system uses a flexible board.

- There is no combined use of these two in any projects

Advantages of Rigid PCB

- These are some advantages of printed circuit boards that are described here.

- Its price is less than the flexible printed circuit board.

- Its lifetime is larger than the flexible board.

- It provides higher quality and density.

- It mostly used in different electronic instruments like mobile phones and computers.

- Its demand and supply are also higher.

Applications of Rigid PCB

- These are some practical applications of this printed circuit board that are described here.

- It used in laptops and computer motherboards.

- Your cell phones, tablets, and some other portable devices are consist of rigid PCB.

- Different file servers and data storage devices also consist of rigid PCB.

- Transmission and receiving circuitry, mobile phone signal repeaters and GPS (Global Positioning System) also use this circuit board.

- It also used in different industrial devices.

- With the uses of electrical and electronic instruments, it also used in different medical devices like testing, x-ray machines, pacemaker, CT scan machine.

- This module also employed different atomic and nuclear systems.

- It also used in automobiles.

- In some complicated circuits, it also used.

Related Posts

- Aluminum PCB (Printed Circuit Board)

- Multilayer PCB (Printed Circuit Board)

- Rigid PCB (Printed Circuit Board)

- Flex PCB (Printed Circuit Board)

- High Frequency PCB (Printed Circuit Board)

- Single Sided PCB (Printed Circuit Board)

- Rigid-Flex PCB (Printed Circuit Board)

- Double sided PCB (Printed Circuit Board)

That is the detailed post on the rigid PCB I have mentioned each and everything related to this PCB board if you have any question about this board ask in comments. Thanks for reading. See you in the next tutorial.

This post is worth everyone’s attention. When can I find out more?

I just could not depart your site before suggesting that I extremely loved the standard information a

person provide to your guests? Is gonna be again ceaselessly

to check out new posts

I have recently started a website, the info you provide on this website has helped me greatly. Thank you for all of your time & work.

After checking out a handful of the blog articles on your site, I really

like your technique of writing a blog. I saved it to

my bookmark webpage list and will be checking back soon. Please visit

my website too and let me know what you think. adreamoftrains

best hosting

This is a great blog.

I love reading your site.

This is a great blog.

Simply desire to say your article is as astounding. The clarity in your post is simply nice and i can assume you’re an expert on this subject. Fine with your permission let me to grab your feed to keep updated with forthcoming post. Thanks a million and please keep up the rewarding work.

This is a great blog.

Considerably, this post is really the sweetest on this notable topic. I harmonise with your conclusions and will thirstily look forward to your incoming updates. Saying thanks will not just be sufficient, for the phenomenal clarity in your writing. I will directly grab your rss feed to stay informed of any updates. Admirable work and much success in your business dealings!? Please excuse my poor English as it is not my first tongue.

You completed a number of fine points there. I did a search on the subject and found mainly folks will have the same opinion with your blog.

Hi there just wanted to give you a brief heads up and let you know a few of the images aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same results.

Thanks for another excellent article. Where else could anybody get that kind of information in such an ideal way of writing? I’ve a presentation next week, and I am on the look for such information.