Hello readers welcome to the new post. In this tutorial, we will have a look at PCB FR-4. There are different types of materials used to make PCB boards but the most commonly used is FR4. In this post, we will cover the details of FR-4, its features, and related parameters. So let’s get started with an introduction to PCB FR-4

Hello readers welcome to the new post. In this tutorial, we will have a look at PCB FR-4. There are different types of materials used to make PCB boards but the most commonly used is FR4. In this post, we will cover the details of FR-4, its features, and related parameters. So let’s get started with an introduction to PCB FR-4

Introduction to PCB FR-4

- PCBs, or printed circuit boards, are the main part of electronic component devices and products. From small devices like phones to cars they are commonly used. There are different types of PCB boards such as single-sided, double-sided, multilayer boards, and rigid boards. Each has its own features and uses

What is FR-4?

- FR-4 is epoxy laminate with glass reinforcement that is frequently used as a PCB substrate. it is created with the use of fiberglass cloth that has been weaved and then thermosetting resin has been added to it.

- When resin has been cured solid and long-lasting materials are used in different application creation

Why is FR-4 So Popular?

- FR-4 is used for PCB board manufacturing due to is low cost and easy access. With that, it is a versatile material that can be used in different projects and boars due to electrical features, good thermal behavior, and mechanical parameters. It is also used to make single- and double-sided boards

FR4 Dielectric Constant

- The printed circuit board (PCB) main component and material is FR-4. its main feature is relative permittivity, called the dielectric constant, which defies the capacitance of this material. The frequency of the field provided to FR4 affects the dielectric constant. At low frequency dielectric constant varies from 4.3 to 4.7. But at high frequency, its value increases to 5.4

- The FR-4 is a composite material due to changes in dielectric constant with frequency. The woven glass cloth impregenated with epoxy resin makes FR4 material. The dielectric constant of composite material is the average weight of the dielectric constant of two components with glass fabric that has a higher dielectric constant than expoy resin.

- Temperature and humidity affect the value of the dielectric constant of FR-4 with the frequency. Normally dielectric constant increases due to humidity and decreases with temperature increases. During the desing of PCBs with FR4 these factors must be considered

- it is good to note that FR-4’s other characteristics, with the dielectric constant, have an impact on how well PCBs function. The thermal conductivity, dissipation factor, and coefficient of thermal expansion are characteristics that are important in defining the Pboard functioning

FR4 Circuit Board

- FR4 is a commonly used material in PCB manufacturing. its main features in PCB are mechanical and electrical qualities with low-cost

- The woven glass fabric which creates composite material called FR-4 has been treated with epoxy resin. The glass fabric has good strength and stiffness, while the epoxy resin has good electrical insulation and protects the board from moisture and humidity.

- Single, double, and multi-layered FR-4 circuit boards are also used. Circuit components exit both sides of double-sided boards, and one sideboard, circuits are only on one side. Multi-layered boards have many layers of circuitry and are used in complicated applications.

- Circuit boards created with FR-4 are recognized for having good thermal properties.

- As it has low thermal expansion material is used to handle temperature changes without cracking or warping In applications where the board faces high temperatures or temperature changes

- its prices are important that is low. FR-4 is commonly used for manufacturers and designers looking to reduce costs because of easy affordability. FR-4 is a high-quality material that is used in many different industries, despite being inexpensive.

Properties of FR-4

There are different features of FR-4 materials listed here

Thermal Properties

it has good thermal stability which means it handles higher temperatures without degradation. So is good for boards that work in high-temperature applications

Electrical Features

It is a good electrical insulator. It has a high value of dielectric strength which means it can handle high voltage without any breakage. it also has a low dielectric constant which means that it can sustain the signal quality for high-frequency values

Mechanical Properties

The strong material FR-4 handles mechanical stress without cracking. It has high flexural strength which means can be bent without any breakage also has a higher tensile strength so it can handle pulling or stretching without breaking

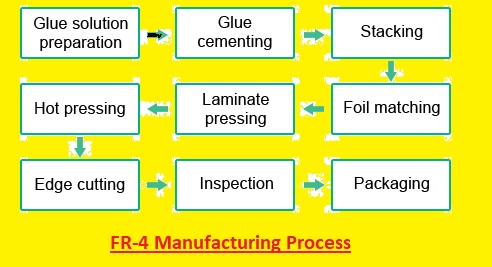

FR-4 Manufacturing Process

Read more Applications of Multilayer PCB

There are different steps used for manufacturing Fr-4 PCBs that are explained here

Lamination

The first step is lamination in manufacturing. It uses stacking players of Fr-4 materials and bonding them through the use of heat and pressure

Drilling

It drilling Holes are drilled in the FR-4 material with the use of a CNC machine. These holes used to attach components to boards

Etching

When holes are drilled board is coated with a layer of photosensitive material. The design of the board is then transferred to photosensitive materials with the use of UV light. The areas which are to be covered through design are then etched with the use of a chemical solution.

Finishing

The last step is PCB finished through the application of a layer of solder mask and a layer of silkscreen. The solder mask provides the protection board from solder splatters, and silkscreen is used to label components on the board

Types of FR-4

There are different types of FR-4 available that come with different features explained here

Standard FR-4

it is a commonly used type of FR4 material. Its Tg value is 130 to 140 °C and is used in different projects

High Tg FR-4

it has a transition temperature of 170 to 180°C so used in high-temperature projects

Halogen-free FR-4

It not have any halogens. It is environment-friendly FR4.

Flexible FR-4

It is used in flexible boards. it has a lower glass transition temperature than standard FR4 which means it can bend without any breaking

Applications of FR-4

Read Also Lead vs. Lead-Free Solder in PCB Manufacturing – 2023 Ultimate Guide

- There are different applications of FR4 explained here

- It is part of Consumer Electronics

- it is part of the Aerospace and defense systems

- Automotive electronics

- It used in Industrial control systems

- It is used in different Telecommunications equipment

Advantages and Disadvantages of FR-4

FR-4 has its advantages and disadvantages explained here.

Advantages

- Inexpensive material

- Widely available in market and industries

- it comes with Excellent thermal, electrical, and mechanical properties

- It can easily handle

Disadvantages

- it is not used for high-frequency applications

- It can be brittle and prone to cracking

- It may release toxic fumes when heated

Choosing the Right FR-4 for Your Project

Here are some factors that you must follow to choose the right FR4 for your projects

- Operating temperature

- Environmental factors

- Signal frequency

- Mechanical stress

Maintenance and Handling of FR-4 PCBs

- Prevent it from moisture and humidity

- Make sure you are inspecting and cleaning the PCB regular basis

- Try to avoid PCB from physical damage

- Properly storing and transporting the PCB

Conclusion

In the PCBs, FR-4 is a versatile and often used material. it is a highly used material due to its thermal, electrical, and mechanical qualities. Understanding FR-4’s features and manufacturing process helps to use the best material for project and ensure its dependability and longevity.