Hello readers welcome to the new post. In this post, we will discuss What is PCB Leds Circuit Board. Currently, the knowledge of PCB led is important. Whether you are an electronic engineer the student must have a proper understanding of these boards. This post will provide a detailed of PCB LED circuit boards, their working, design uses, assembly process, applications, and related parameters. So let’s get started with What is PCB Leds Circuit Board

Introduction to LED PCBs

Light-emitting diodes are called LED and becoming famous for lighting purposes in different industries.

LED is solid-state lighting that transforms curent into light with the use of semiconductors. Then normal light bulbs use less energy about 80 percent and work for 25 timers longer.

It has many advantages like small size and environmentally friendly working.

PCB boards are important for supporting LEDs. These are thin boards created with fiberglass metals or other materials with the connection of electronic components. These boards are part of many LED applications. They can support the LED and shit heat away from bulbs to increase their working and avoid getting damaged.

LED PCB Construction

According to board applications, PCB manufacturing has many materials, designs, and processes. The main important feature is creating the core of the board. PCB core comonly materials are

FR-4:

- FR4 comes with glass and epoxy and common types of core materials. It is fire resistant and not effective for heat transfer.

Epoxies:

- They are commonly used. but not durable like other materials but has less cost.

Metal-core:

- The metallic core board comes with aluminum alloy with other metals and laminated copper These materials used for applications that have heat transfer and provdies good thermal conductivity and electrical insulation.

Applications of PCB LED Circuit Boards

LED Lamps

The main use of LED baord is in different types of LED lights. LED board comes with good theraml conductivity and LED lights have high power. These lights can be used in agricultural planting, stage lights in theaters, and ship lights on the sea are made with LED CB

Indicators:

Data Communication:

LEDs are used for data communication like data transfer. The optic fiber technique is based on LED to send data at differnt points. That VLC uses LED for the main data transfer medium since LED offers high data bandwidth that helps for proper communications.

Machine Vision Systems:

The best use of LED is a barcode scanner in the machine vision system. Normally the red LED is used in barcode scanners that is used at supermarkets and grocery stores. The LED is the bright light source and its compact structure makes it best for machine vision systems.

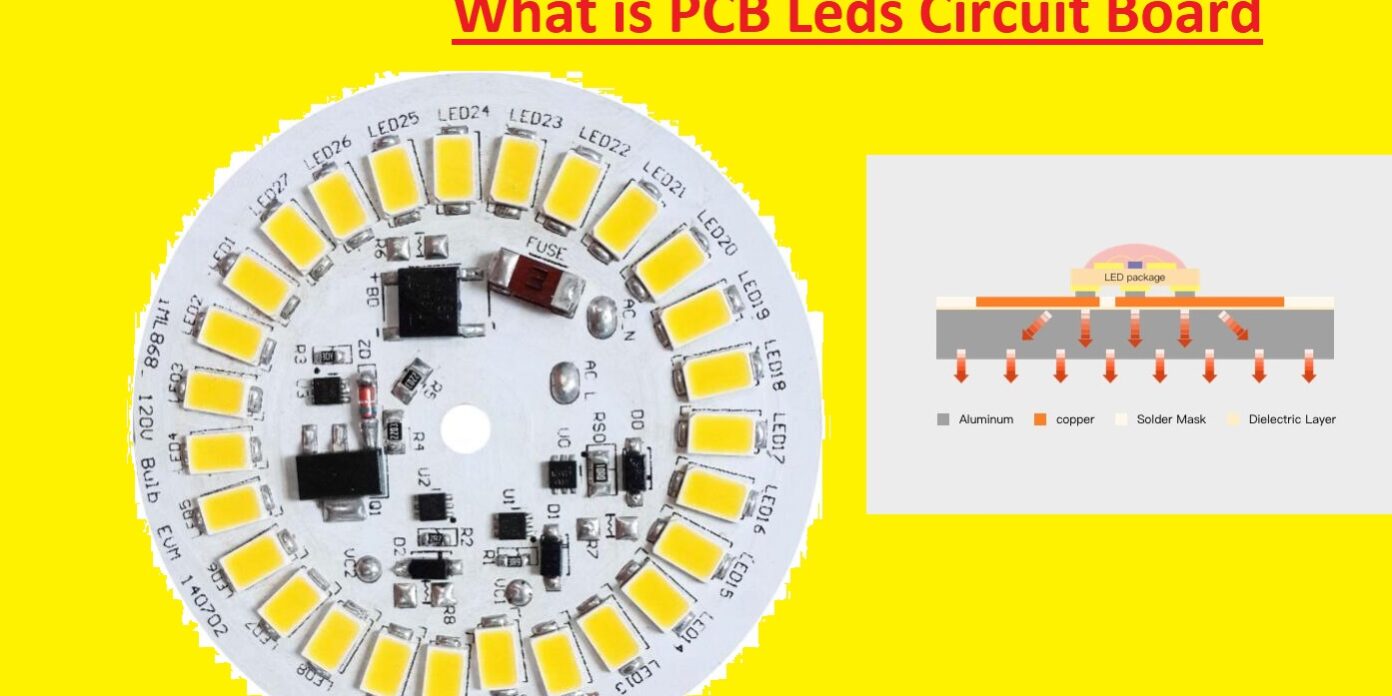

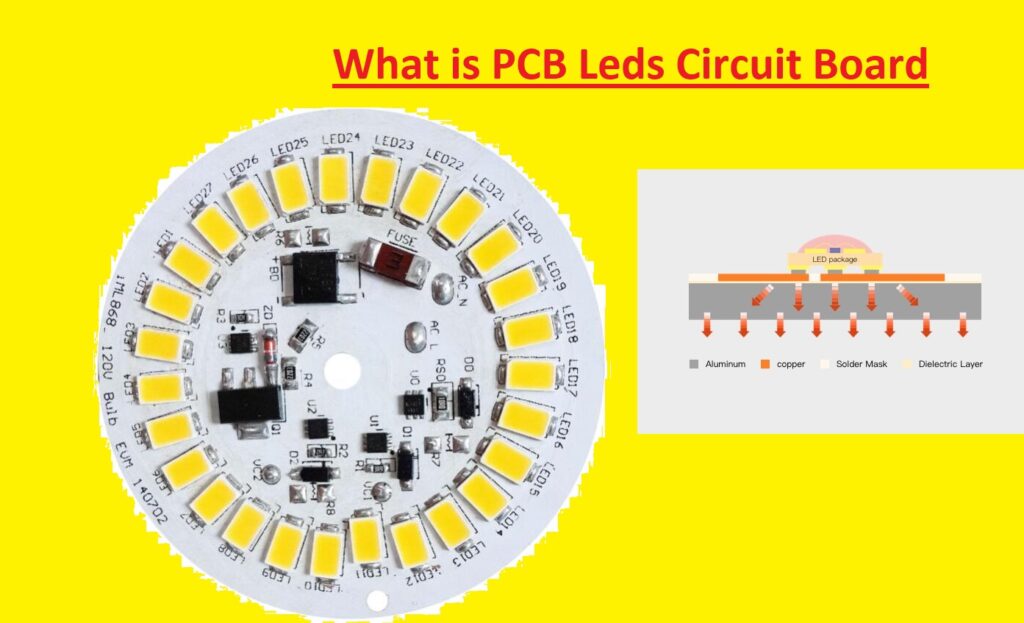

Aluminum LED Circuit Boards

Aluminum boards are a common type of LED pcb. These boards are configured on an aluminum alloy base that has aluminum, silicon, and magnesium. These led pcb materials come with different features for different uses.

Main layers of Aluminum PCB are

base layer

- The base layers come with an aluminum alloy sheet and is layers where other components of the board are configured.

thermal insulation layer:

- The thermal insulation layers come with ceramic polymer and protect the board from thermal and mechanical damage. When current passes through circuits their layers get heat given and transfer to aluminum layers where it disperses.

circuit layer:

- This layer has copper circuits that are made according to the design of LED pcb boards

Types of aluminum LED PCBs

Flexible aluminum:

- The flexible led board has aluminum, polyimide resin, and ceramic filler that increases insulation and flexible features with good thermal conductivity. These boards do not need connectors cables or other fixtures. But their design helps to bend once and get a required place.

Hybrid aluminum:

- In this boards fuse aluminum base metal with non thermal materials like conventional FR4 board. The use of these materials reduces cost and provides rigidity with good heat dissipation.

Multilayer aluminum:

- Multilaery aluminum PCB comes with more thatn 3 layers of conductive materials. These boards have high working and offer good heat dissipation. But they have fewer heat transferring featues than others. They are different from single or double-layer boards

Using SMD Components on LED PCBs

- Resistors: Resistors are employed to restrict the current through the LEDs.

- Capacitors: Capacitors are deployed to store energy and filter noise.

- ICs: ICs are integrated circuits that have many electronic components on a single chip.

- Inductors: Inductors are used for energy storage and create magnetic fields.

- Transistors: Transistors are employed to amplify or switch signals.

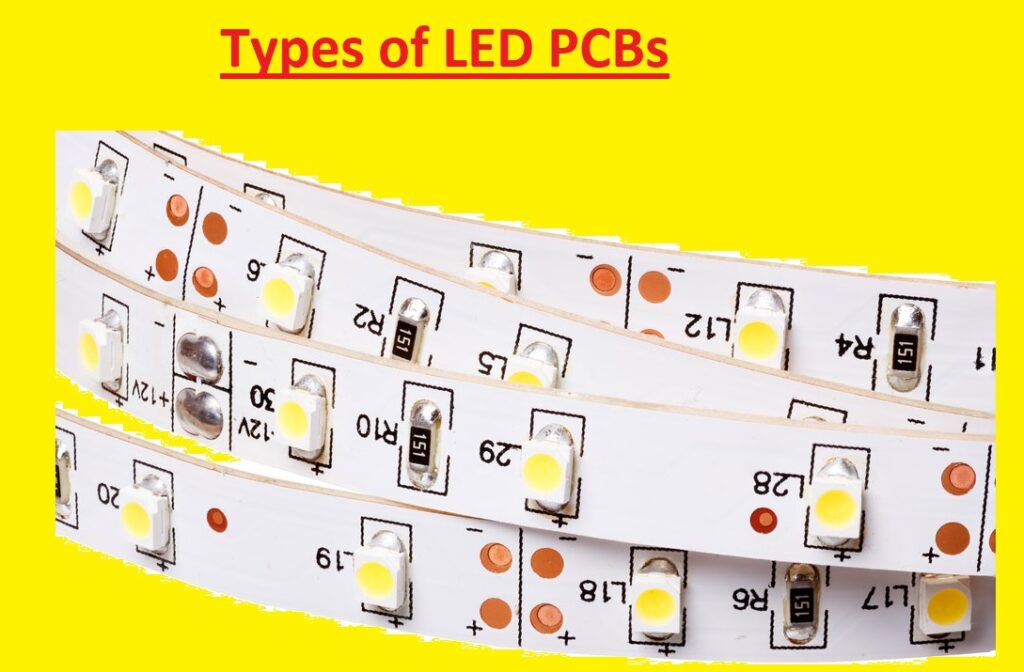

Types of LED PCBs

- Single-layer LED PCBs:

- Multilayer LED PCBs:

- Heatsink LED PCBs:

- Flexible LED PCBs: They are used for applications where a rigid PCB is not practical, like wearable devices and curved surfaces.

Advantages of LED PCB

- Lightweight, low-profile

- dimensional stability

- thermal expansion

- Low power consumption

- ·heat dissipation

- ·Lower cost backlit membrane switch

- Dust and moisture resistant

- Make it easy to integrate into complex interface assemblies

- ·Comes in different types of sizes, colors, and intensities

Read also:

- What is Ball Grid Array (BGA) on a PCB Board

- Matte vs Glossy in PCBs

- Learn How PCB Circuit Board Soldering Guide for Beginners

- Introduction to PET-Flexible PCB

- PCB Immersion silver Surface Finish

- Single Sided PCB Board, Construction, Working, Features & Applications

FAQs

How do LED circuit boards work?

LED is mounted on the PCB board layer. The heat produced through the board during working is transferred through the insulating layer to the metallic base and this heat is shifted through the metal base layer to dissipate heat from the device.

What are LED boards used for?

They are used for information display,, advertising, and in various indoor settings such as shopping malls, retail stores, airports, stadiums, and more. Indoor LED displays are versatile and employed at different locations and for different purposes.

What material is an LED circuit board?

The Aluminum boards are a common type of LED PCB board. These boards are configured on an aluminum alloy base that comes with aluminum, magnesium, and silicon. These LED board materials come with differnt features according to the use

What are the main LED materials?

The main LED semiconductor materials are Indium gallium nitride (InGaN): blue, green, and ultraviolet high-brightness LEDs. Aluminum gallium arsenide (AlGaAs): red and infrared LEDs. Aluminum gallium indium phosphide (AlGaInP): yellow, orange, and red high-brightness LEDs.

How is LED PCB made?

Follow these points for LED pcb manufacturing.

Design LED PCB:

- Select Materials:

- Transfer the Design:

- Etch the Board:

- Drill Holes:

- Solder the Components:

- Test LED PCB:

How is LED constructed?

The construction of lED is an easy proces since it is made through the deposition of 3 semiconductor materials layers over the substrate. These 3 layers are configured one by one in such a fashion that the upper part is P middle is active and the lower is the N region

What is LED plastic made of?

Mostly led cover molded with transparent plastic, with intrinsic or molded in frosting. Less Cost lamps can use less cost plastic such as polystyrene, but mostly polycarbonate is used due to its stronger structure and gives a superior finish

What color is LED material?

- Indium gallium nitride (InGaN): blue, green and ultraviolet high-brightness LEDs.

- Aluminum gallium indium phosphide (AlGaInP): yellow, orange and red high-brightness LEDs.

- Aluminum gallium arsenide (AlGaAs): red and infrared LEDs.

What are the types of LED?

- Through-Hole LEDs:

- Surface-Mount LEDs:

- High-Power LEDs:.

- RGB LEDs:

What are the features of LED?

- Energy Efficiency:

- Long Lifespan:

- Environmentally Friendly:

- Durability:

- Wide Range of Colors:

- Instant On/Off:

- Compact Size:

What is the purpose of a solder mask on an LED PCB?

The solder mask is a protective layer that saves solder bridges and makes sure that solder is applied to the requried points on board assembly.

Can I use a single-sided PCB for my LED project?

Single side boards are best for simple led projects with fewer component connections. But complicated circuits, use double-sided or multi-layered PCBs.

How can I improve the thermal performance of my LED PCB?

For increasing thermal operation use metal core PCB or use heat sinks for heat dissipation effectively

Are LED PCBs only used for lighting applications?

As LED pcb are used in lighting circuits, they also used in automotive, medical devices, and consumer electronics.

Can I rework or modify an already assembled LED PCB?

yes, it is possible to rework, but it need proper desoldering and resoldering of components. best is to avoid reqork for painting board quality