Hello, readers welcome to new post. In this post, we will discuss Construction of Rigid PCB. PCB board is very significant board in the electronic industry and is used in each and every part of engineering projects and circuits. Different types of PCB boards are in industry and electronics on the basis of their uses structure and different features. Common types are single layer pcb double layer, multiple layer, and Rigid PCB.

Hello, readers welcome to new post. In this post, we will discuss Construction of Rigid PCB. PCB board is very significant board in the electronic industry and is used in each and every part of engineering projects and circuits. Different types of PCB boards are in industry and electronics on the basis of their uses structure and different features. Common types are single layer pcb double layer, multiple layer, and Rigid PCB.

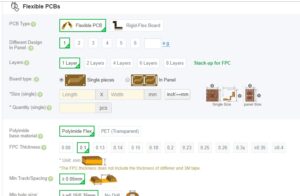

Rigid PCB can be created in different structures like single layer double layer multiple layers on the requirements of users and applications. It is used in such circuits that after creation not need any changes due to the rigid behavior of the board. There are different PCB manufactures are working that offer PCB-based services but one the best in all PCB-based services are PCBWAY. PCBWAY is a high-level PCB supplier and producers offer PCB fabrication and prototyping services having the latest equipment and professional engineers. Their fully assured PCB fabrication features with the design of the board for production permit them to sustain the high user retention rate. You can also get the advanced PCBs like flex PCB, rigid-flex PCB from PCBWAY at good rates with high quality features

The main purpose of PCBWAY is to provide customers with high-quality, less expensive, and fast delivery. In terms of cheaper electronic projects, it is the first PCB supplier to provide PCB prototyping service at the price of $5/10pcs. If you use the coupons after a new registration, the price will be reduced to zero dollars They provide a template for ten dollars and also has a similar price for different colors of solder mask. The delivery time of the product is usually two to three days.PCBWAY’s main features are fostering relationships with the open-source community, and it also sponsored the 2017 Open-Source Hardware Summit.

As part of sharing your ideas with the PCBWAY community, you can very easily communicate and send your ideas with other members, and you also have the option to vote for the most famous PCB design.

If other community members like your design the most, you will get a ten percent commission. So get the other PCb-based services must visit the PCBWAY for your rigid PCB projects they are offering the rigid pcb at good prices and high-quality board. So let get started

What is Rigid PCB Board

- The Rigid PCB is part of the PCB family and used in different types of projects. There is slid substrate used in the construction of this board to avoid the different damages and corrosion facts.

- Its common application in the circuit board of computer that called motherboard is created with use of this board.

- A computer motherboard is created through the use of a multi-layer rigid PCB that helps to transmit the power from the main supply ot other parts of the computer like RAM, CPU etc

- A rigid PCB board is mostly preferred for conditions where normal PCB can not sustain and damages easily due to environmental conditions.

- These boards come in different layers from single to multiple like eight to ten layers can be created of this board.

- If we compare it to the flexible board will find a clear difference in them. that flexible PCB has flexible natures than rigid pcB

Rigid PCB Characteristics

- There are different characteristics of these PCB boards are discussed here

- Rigid PCB board part of PCB family that is not structured like the flexible PCB board since there is shape change in the rigid is not possible or can damage since it consists of FR4 material enhances its stiffness

- There are copper traces and different tracks are created on this board for the connection of different comments on the board to make the circuits. to enhance the rigid and strength of the board there is the rigid substrate used in the board

- Its main example where the rigid board is sued are motherboard of a computer having a rigid substrate

- After the creation of this board not possible to change its dimension and folded nature

- Its prices are low than the flexible board it is a normal board that is mostly used in different electronic projects

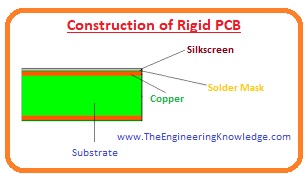

Construction of Rigid PCB

- The construction process of rigid PCB is discussed here. It has some parts that are listed here

- Substrate Layer

- Copper Layer

- Solder Mask Layer

- Silk Screen

Substrate Layer

- The substrate material also named as base material is created with fiberglass

- FR4 is mostly used as substrate material and commonly used category of fiberglass which enhances the rigid and stiff nature of the board

- WIth FR4 other base materials like epoxies and phenolics are used but are less effective than the FR4.. But has less cost and different lousy smell

- Phenolics have fewer decomposition temperatures in results damage to the board if solder is working on the board for a larger time interval

Copper Layer

- At the substrate layers, the copper layer is positioned at the board through use of a certain quantity of heat and adhesive material

- Currently, boards has copper on both sides but some less expensive boards have single-sided copper layers

- Every board has its different value of thickness and is measured in ounces per square foot

Solder Masks

- After the application of copper layers, a solder mask is applied. It helps to protect the copper layers from any environmental conditions damage and corrosion

Silk Screen

- Silkscreen is applied on the solder mask. it helps to make symbolic representations of different components to get a good understanding of the board for making circuit

- There are different colors of silkscreen like grey red black and yellow but white color is mostly used

Differences Between Rigid PCB And Flexible PCB

- The main differences between rigid and flexible PCBs are explained here

- In different electronic projects normal rigid PCB board is used. With the advancement in technology, different projects demanded different features and some are not required in certain projects rigid pcb is not used due to its non-twisted nature

- So professionals think about the flexible PCB for such projects where rigid board is not used.

- The construction of flexible and rigid boards are the same but with some differences like cost softness and flexible nature

- Thee is a need of extra requirements for a flexible board when it is used in projects. With that certain features are needed to handle the cracking issues in case of board bend

- Flexible pcb is more expensive that the rigid board. But in the case of projects overall prices may be larger for rigid board but in individual board flexible board is expensive

- Some less expensive devices are created with the use of rigid boards like toys, solid states, keyboards, and some electronic projects.

- FOr high-performance projects flexible board is preferred used since they not need connectors or tiny structures than the rigi board and will be applied in phones, etc

- TO ensure the products strength and flexible nature rigd and flexible boards can be used together

- Some flexible boards come with similar structures but not like the rigid circuits

- FOr applications where bending of board is needed flexible boards are used

Uses of Rigid and Flexible Boards

- Flexible products are more costly than rigid boards. it is that on the basis of projects when flexible pcb used is less expensive than the rigid board.

- Different electronic modules like laptops computers keyboard Tv uses rigid board While flexible boards are used in high-performance structure like GPS, tablets phones cameras

- Due to easy installation led lights uses flexible boards

Applications of Rigid PCB

- Rigid boards can be used in heavy weight and fewer weight projects. To get the fines connection and variable resistance multilayer rigid board was used For handling the high volts and high-frequency heavy duty board used

- Rigid PCB used in heavy machines like EMG, tomography, and MRI in medical devices

- In avaitions hgih temperatrues applcations wokrs. Where rigid boards are created through the use of copper and aluminum substrate to handle the high-temperature applications. Alos used in APU, airplan cockpit, power convertrers.

- It is also used in automobile applications so here heavy cooper boards are used. to avoid effect of heat engine, high-temperature guard is used

- It is also used in ac to dc converter ECU sensors as well

Advantages of Rigid PCB

- These are some advantages of printed circuit boards that are described here.

- Its price is less than the flexible printed circuit board.

- Its lifetime is larger than the flexible board.

- It provides higher quality and density.

- It is mostly used in different electronic instruments like mobile phones and computers.

- Its demand and supply are also higher.

That is all about the Construction of Rigid PCB all details has explained. Alos must visit the PCBWAY for high-quality boards.