PCB needs a further finish to decorate its characteristics. There are differnt varieties of techniques used but immersion silver is the maximum normal technique. However, they still, specialists face problems to perform this process or making comparisons to different styles of finishes available. Right here we can have specific have a look at immersion silver and its features.

What is Immersion Silver

Immersion silver is also called IM silver, silver paling, and ENIAg. it is a common type of finish that is easily applied to conventional printed circuit boards. Almost one-tenth of boards are created through the use of these finishes. The board surface integrity is the main part of PCB construction. For this purpose different processes are applied on the board. Immersion silver finish helps boards to avoid the effects of oxidation, temperature fluctuations mechncal stress, and some other environmental conditions.

Pure silver is the best option for surface treatment materials since it provides different characteristics such as ductility, thermal conduction, soft surface, good electrical conduction, and resistance to water and oxidation. These features help immersion silver become a commonly used surface finish for PCB manufacturing. In this process, a thin layer of silver having a thickness of 0.1 to 0.5 um is chemically created at the copper surface which protects the copper from oxidation effects and enhances the solderability.

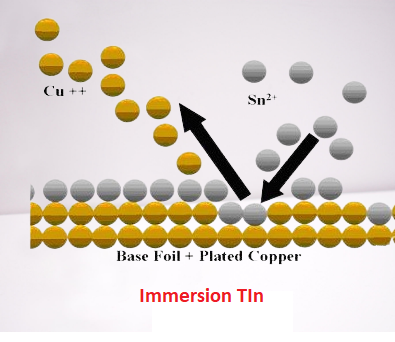

Immersion silver follows the Galvanic effect. Operated through the difference in emf and redox potential among copper and silver, silver ions get electrons from copper then copper gets dissolved, and silver precipitates. There is displacement reaction exists between silver ions and atoms of copper in the solution.

Immersion silver is an environment-friendly surface treatment and follows the RoHS. It provides good surface planarity that is favorable for high-density circuits and less spacing surface mounting.

Immersion Silver Chemical Equation

Silver immersion is the deposition of a thin layer of silver at the PCB board copper layer through the use of a chemical reaction. The equation of that chemical reaction is given here.

2Ag++Cu═Ag+Cu2+

This explained that copper is partly dissolved at the surface and releases two electrons in the solution of silver. Silver that is dissolved gets two electrons and is converted into metals and gets deposited on the copper surface of the board.

How Immersion Silver applied

- For the application of silver immersion, there are some steps involved that are explained here.

Board Cleaning

- In this step, the board is cleaned properly to minimize the effect of oxidation and dust particles existing on the PCB board to make it neat and clean. This process is the initial tin immersion that makes the PCB ready for tin application. In this process air trapped removed existing in the plate through holes.

Micro-etching

- In the etching of the board, there is non required copper is eliminated from the board. This process helps to make modifications to the board surface. Eliminating the additional copper from the board just the main circuits of board existing on the board is a clear form

Board Pre dipping

- In this phase, the board is placed in sulphuric acid. This acid dipping process helps the board surface to get the silver coating easily. With that, the board gets protection from environmental conditions like oxidation and corrosion.

Silver Immersion application

- In this phase there is copper metal is minimized through the use of silver. In this way, silver is applied on the board. The silver application process must be slow and steady with careful configuration. So in a result, we get a uniform layer on the board.

Board Dipping after Silver Applications

- Here board was again dipped to apply the antioxidant compounds that help the board to avoid oxidation and corrosion

Problems for Immersion Silver Finish

Here are some issues related to immersion silver finish are explained.

- Silver Whiskers

- Tarnish

- Galvanic Effect

Silver Whiskers

Silver whickers cause when the board is exposed to hydrogen sulfide and environments having high moisture. So it causes the short circuit of PCB components. To avoid this problem conformal coating is applied to the silver layer

Tarnish

Immersion silver board does reaction with chlorine and sulfur after getting exposed to air. So this reaction makes the sliver layer colorless and also affects the soldering features. The simple option to avoid this problem is to follow good storage rules.

The other option is to store the board in sulfur-free packaging to minimize tarnishing. Ensure that the packaging is air free and again close it properly when removing a board from the packing. With that anti-tarnish bath can be used in the last phase of plating

Galvanic Effect

The galvanic effect is like the corrosion phenomena. Normally silver oxidation of copper and reduction of silver ions and their deposition are done at the same time in an immersion process. The copper layer is working as an anode and cathode. That makes the uniform coating on the boad surface. In this situation, there is gap exists between the copper layer that is created by corrosion and the silver supply deteriorates. As a result copper, existing spaces operate as anode giving electrons to react with silver. Sp silver deposit on the copper pads that has to be unexposed. As a result, PCB gets malfunctioned

How to Avoid the Galvanic Effect

- Here are some steps discussed that help to minimize the galvanic effect

- Use immersion silver process having less pH that is helpful for less corrosion but it will increase the silver thickness

- Mico-etching performed must control and apply it for the required quantity of solution

- Modify the design of the PCB to avoid the copper surfaces not to connect with small copper lines

- Make some optimization for the pre-treatment, curing, and imaging process. With that solder mask must be chemically resistant

- It is reworkable finishes

Immersion Silver Surface Finish Advantages

- Immersion silver provides eh flat surface areas. This is helpful for SMD components connection. It has surface planarity which makes it easily accessible for manufacturers. This surface finish he’s to connect the components like Ball Grid Array easily

- It is an environment-friendly finish and fulfills the industrial standard RoHS

- it provides good solderability after getting numerous thermal excursions. The surface permits the solder to spread out smoothly. So it is helpful for soldering components

- Immersion silver finish provides good conductivity which makes it the best option for high-speed signal circuit designing.

- Its low-cost, immersion silver is preferred and used by numerous PCB designers. it is the finest option for boards that are created with limited expenses

- It has fewer charges for a lead-free finish

Immersion Silver Surface Finish Disadvantages

- With different advantages, this finish also has some drawbacks that are listed here

- It cannot handle the peelable masks so not used for this finish

- Its operation areas is smaller which limits supply chains parameters

- It is not commonly affordable boards

- Its handling is difficult so it must need to use twenty-four hours after manufacturing

- It is vulnerable to chloride and sulfuric which are inorganic acids

- It needs a certain type of packaging if the packaging is opened and not all boards are employed it should be again resealed as soon as possible

During the application of immersion finish some issues can produce like galvanic, tarnish, etc. So proper measures are taken to solve these issues. the finest option for this finish is handling of material used and its proper packaging needed