Hi, guys welcome to the new post. In this post, we will discuss What is Ball Grid Array (BGA) on a PCB Board. Ball Grid Array (BGA) is a packaging technique used in electronic circuit boards that has different benefits then other packaging techniques. It is used due to its features to handle large interconnections in less area. so used in high-density applications. In this post, we will learn Ball Grid Array (BGA), and other parameters. So let’s get started What is Ball Grid Array (BGA)

What is BGA?

- BGA is a surface-mount packaging where solder balls are arranged in a grid-like layout at the component bottom. These solder balls make electrical connections between components and the PCB board. This packaging is mainly uses microprocessors, integrated circuits, and other complicated electronic components.

BGA vs. Other Packaging Technologies:

| Feature | BGA | PGA | LGA |

|---|---|---|---|

| Package type | Ball grid array | Pin grid array | Land grid array |

| IC connection | Solder balls | Pins | Solder balls |

| Package size | Compact | Larger | Larger |

| Heat dissipation | Good | Fair | Good |

| Cost | expensive | Less costly | Less costly |

| Complexity | More complicated | Less complicated | Less complicated |

| Applications | High-performance devices, devices with a lot of ICs thin devices, | , devices that do not need high-performance | devices that do not need high-performance |

Advantages of BGA:

- High Density,

- Reliable Construction,

- Good Performance at High Speeds,

- Less Component Damage

- Reduces Overheating

BGA Assembly Process:

The BGA assembly comes with different phases. It operated with the use of solder paste at the board and then component configuration use of the automated machine. The board then moves to reflow soldering where solder balls melt and make a reliable connection. The board goes to inspection to confirm accurate alignment and quality of the solder joint

What is a Cold Solder Joint and How Can You Prevent it?

Difficulties in BGA Assembly:

There are some challenges involved in this process. The Main is the correct alignment of the BGA component since it does not have leads. BGA components also require correct control of the reflow soldering technique to have fewer issues such as solder bridging and voids. With that inspection of hidden joins and casues of different defects is the main issue

BGA Inspection and Testing:

DIffernt inspection methods are used to provide quality BGA components. X-ray inspection is used for getting hidden solder joints, and optical inspection finds errors at the surface of the component. With that electrical testing such as bal pull tests, and ball shear are used to asses the mechanical strength of solder joints

BGA Rework and Repair:

To have high-quality BGA elements rework and rearing techniques are used. Rework removed faulty components, cleaned them, and replaced with new if they were faulty. There is latest tools and expertise are used to do this process to prevent any damaging

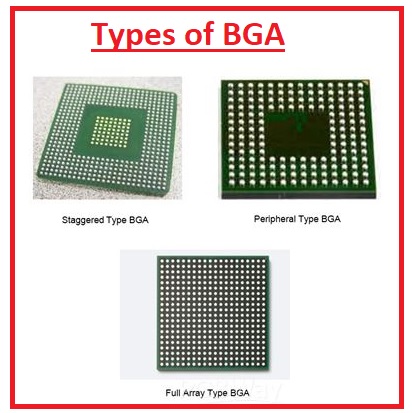

Types of BGA

1. Ceramic BGA (CBGA):

This type of BGA comes with the use of ceramic materials and has good thermal features and a reliable structure. The ceramic substrate has good heat dissipation, making CBGA good for projects that generate high heat. This packaging is used in harsh environments and high-performance electronic devices.

2. Plastic BGA (PBGA):

it uses plastic for base materials. They are less costly for different projects. This packaging has a plastic substrate that provdies mechanical support and insulation. Used in different mobile phones, game consoles laptops, etc

3. Flip Chip BGA (FCBGA):

This packaging was created for high-density circuits and has good electrical operation. In this module, IC is flipped at our side and mounted on a substrate provdies smaller interconnects and decreasing signal delay. This packaging has less power use, high frequency, and good thermal featues

4. Micro BGA (MBGA):

This packaging has a compact desing and a small footprint and pitch. it is used in space-constrained uses such as mobile devices, that need miniaturization.. This packaging also has a high-density connection and handles the ever-shrinking size use of of modern electronic devices.

JLCPCB BGA Technology:

As a well-known PCB supplier and services provider is JLCPCB also offers BGA services. The BGA-PCB products are accurately tested at JLCPCB with the use of the proper latest techniques before proving to customers. Their BGA services are according o modern electronic desing requirements and make sure different customers’ needs for BGA integration in board desing and satisfy clients with the highest degree of accuracy and quality.

. Here are some of their BGA technology’s salient features:

- Advanced Manufacturing Equipment:

- High-Precision Assembly:

- X-ray Inspection:

- Design Guidelines:

- Quality Assurance: JLCPCB follows the quality guidelines to ensure good performance of BGA assemblies.

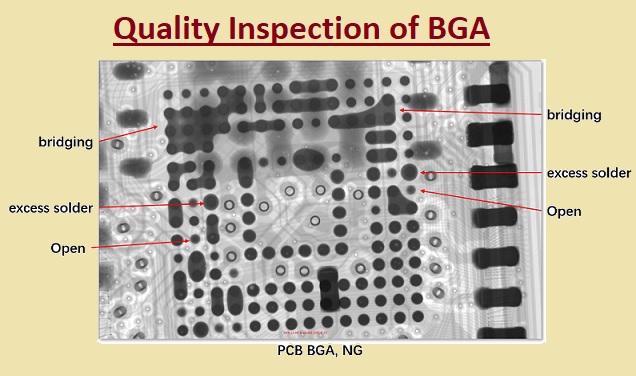

Quality inspection of BGA

Quality inspection of BGAs is the main factor in ensuring solder joints are correctly created and that IC is mounted on board. Some techniques used for inspecting BGAs, include:

- Visual inspection: it is a simple technique used to inspect visual checking of the solder joints to find faults such as cracks, voids, or cold solder joints.

- Automated optical inspection (AOI): it is the latest method for inspection that uses a computer to automatically inspect BGA faults. AOI can find different errors than visual inspection

- X-ray inspection: it is a process of inspection with high accuracy and can be used to find the smallest faults in the solder joints. X-ray inspection is used in high-reliability applications, like military and aerospace.

Defects of BGA

- Cold solder joints: it is made when solder does not accurately wet the surface of ICs. it results in poor electrical connection and damages the ICs

- Voids: it caused when air packets in solder joints. It makes an importer electrical connection and damages the circuit

- Cracks: When solder joints is not strong enough to handle stresses that are applied to them.

Elimination of BGA defects:

Detaching of components: BGA component defects can be rectified by first detaching the components from the board. It can be done by careful heating of localized components on the PCB board, which melts down the solder joints, and we can vary the components and fix the solder connections as needed

BGA rework process: This process is done in a dedicated rework station in the factory., where BGA board components are heated with the use of the infrared heater. Heat level can be monitored by thermocouple. To raise the package from the underlying board a vacuum module is used along with other equipment.

Localized heating: the heating method is done carefully and it is limited to the defective area on the PCB board. Localized heating to confirm the safety of neighboring components on the PCB.

FAQs

What is a BGA in PCB?

A BGA, or ball grid array, is surface-mount packaging used for integrated circuits. This packaging is used in mount devices, graphics processing units, microprocessors, and memory chips. it is more compact than pin-grid array (PGA) packages, and they used for good heat dissipation.

What is the difference between BGA and LGA?

| Feature | LGA | BGA |

|---|---|---|

| Connection method | Pins | Solder balls |

| Pin/ball arrangement | Grid-like pattern | Grid-like pattern |

| Contact type | Flat surface | Solder ball |

| Pitch | Typically larger | Typically smaller |

| Thermal properties | Good | Better |

| Repairability | Easier | More difficult |

| Cost | Lower | Higher |

What is the difference between a pin grid array and a ball grid array?

| Feature | Ball Grid Array (BGA) | Pin Grid Array (PGA) |

|---|---|---|

| Connection type | Solder balls | Tiny pins |

| Connection arrangement | Square grid of rows and columns | Square grid of rows and columns |

| Density | High | Lower |

| Heat dissipation | Excellent | Good |

| Impedance | Low | Higher |

| Ease of unsoldering | Easy | More difficult |

| Deballing | Possible | Not possible |

| Reballing | Possible | Not possible |

| Portability | High | Lower |

| Thermal and mechanical properties | Excellent | Good |

| Applications | CPUs, GPUs, other high-performance ICs | CPUs, other ICs |

| Package variants | Many | Fewer |

| CPU sockets | Many | Fewer |

| Cost | Higher | Lower |

What is the difference between PCB and BGA?

A PCB,, is a board has conductive pathways that connect electrical components. A ball grid array is a type of IC packaging that uses solder balls to connect the IC components to the PCB.

What are the 3 types of PCB?.

- Single-sided PCBs have conductive pathways on one side of the

- Double-sided PCBs have conductive pathways on both sides of the board.

- Multilayer PCs have conductive pathways on multiple layers of the board.

What is the function of BGA?

The main function of BGA is to connect integrated circuits with boards. Solder balls at lower the BGA melted in the soldering process, making the connection between the Board and components.

What is the advantage of BGA?

. BGA packages are compact and used for smaller devices. These packages also have good heat dissipation, which is best for devices that prodcues a lot of heat.

How many types of BGA are there?

e many different types of BGA packages, Some are listed here

- Low-profile BGA packages

- High-density BGA packages

- Flip-chip BGA packages