Hello, fellows, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at Power Flow and Losses in DC Machines. There are 2 main categories of dc machines first one is DC motor and the second one is DC generator. The motor converts electrical power into the mechanical power and dc generator transforms mechanical power into electrical power. During these power conversions either mechanical to electrical or electrical to mechanical, some power losses occur that decrease the quantity of power conversion.

Hello, fellows, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at Power Flow and Losses in DC Machines. There are 2 main categories of dc machines first one is DC motor and the second one is DC generator. The motor converts electrical power into the mechanical power and dc generator transforms mechanical power into electrical power. During these power conversions either mechanical to electrical or electrical to mechanical, some power losses occur that decrease the quantity of power conversion.

Due to these power losses heating produces that affect the operation of dc machines. Due to these power losses the efficiency of machines also decreases. In today’s post, we will have a detailed look at these power losses and their effects on machines. Also, discuss how we can reduce these power losses. So let’s get started with the Power Flow and Losses in Dc Machines.

Power Flow and Losses in DC Machines

- The efficiency of any dc machine either dc motor or generator is given as.

=(Pout/Pin) x 100%

- If we define the losses that we will find that it is the difference between input and output power of dc machines.

- In the mathematical expression, it can be defined as.

=(Pout-Ploss)/(Pin) x 100%

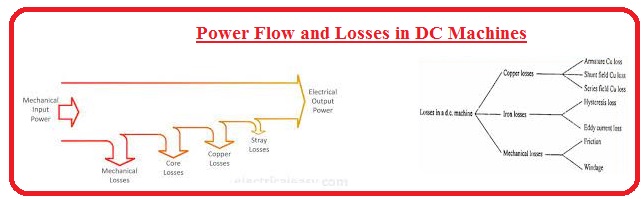

- 5 main types of losses occur in dc machines either its motor or generator.

- Copper Losses or I2R Losses

- Brush Losses

- Core Losses

- Mechanical Losses

- Stray Losses

Now we discuss all these losses one by one with the detailed.

Copper Losses

- As you can understand from the name of these losses that are copper losses mean that losses occur at the windings of machines.

- There are 2 types of windings first one is field winding that exists at the stator and the second one is armature windings that exit at the rotor, at these two windings coppers losses occurs.

- The value of these losses for armature and copper windings can be given as.

Armature winding losses = PA =IA2RA

Field winding losses = PF= IF2RF

-

- In these two above given equations.

- PA stands for armature losses.

- PF field windings losses.

- IA is current passing through the armature winding.

- IF is current passing through the stator windings.

- RA is armature resistance.

- RF is field windings resistance.

Brush Losses

- These losses occur at the carbon brushes that are connected with the output terminals and commutators of machines.

- The mathematical expression for these brushes is given as.

PBD=VBDIA

- In this equation.

- PBD is the loss at the carbon brushes.

- VBD voltage losses at the brushes.

- IA is the armature current.

- The purpose that the brush losses are found in this way is that the voltage drop at the brushes remains same at the different values of currents.

Core Losses in DC Machines

- There are two types of copper losses in dc machines first one is eddy current losses and the second one is hysteresis losses.

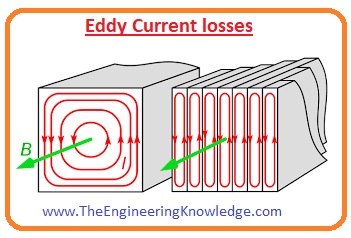

Eddy Current losses

- If we discuss Faraday law that says that the rate of change of flux in any conductor produces a voltage in that conductor.

EMF =dø/dt

- If we apply this law on dc machine that we come to know that when the rotor of the machine rotates in the field of the rotor than voltage induces in the rotor that current starts to flow through the armature winding this current known as eddy current.

- The mathematical expression for these current is given as.

Pe = KexBmax2 x f2 x t2 x V

- We can describe here the component of this equation as.

- Pe stands the power losses due to eddy currents.

- Ke is constant for these currents.

- B is flux density.

- f is the frequency.

- t is the thickness of the materials used.

- V is the volume of the core of machines

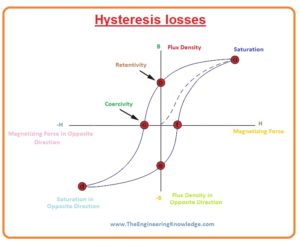

Hysteresis loss

- The cause of these losses is the energy required to magnetize and demagnetize the core of the machine.

- With the increment in current for magnetization of core, the value of flux also increases.

- But when we decrease the current that used for magnetization the value of corresponding flux don not decreases with the current.

- When the value of the current becomes zero then there is some value of flux exits in the core.

- To minimize the flux in the core and external force is applied that causes hysteresis losses. The opposite polarity of field is provided to the core that minimizes the ramming flux in the machine.

- The negative magnetization depends on the material used for the construction of core.

- The mathematical expression for these losses is given as.

Pb= η x Bmaxn x f x V

- In this equation.

- Pb denotes the hysteresis losses

- Η is Steinmetz hysteresis coefficient. Its value is from 1.5 to 2.5l

- Bmaxn is flux density.

- f is frequency.

- V is volume of material used for core construction.

- In the given figure, you can see the curve for these losses.

Mechanical Losses

- These losses occur in dc machines due to the mechanical effects that occur in dc machines. These are 2 main facts that cause to mechanical losses first one is friction and second is windage

- Friction losses occur due to the bearings that exit the shaft of machines. The windage losses occur due to the air among the rotatory portion and their casing.

- These losses changes with the cube of speed of revolution of the machine.

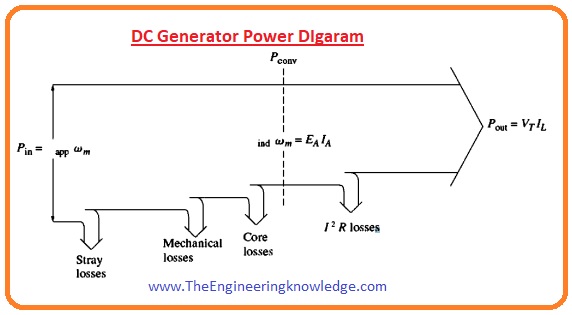

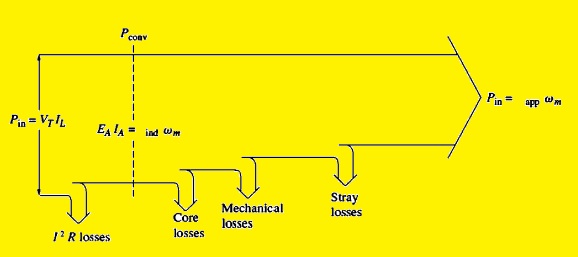

DC Machines Power-Flow Diagram

- One of the simple methods to find the values of different losses in dc machines is to draw their power flow diagram.

- In the given figure, you can see the power diagram of dc generator.

- In this figure the mechanical power is input and after eliminating stray losses, mechanical losses (friction and windage losses), core losses than we have an electrical output that is given here.

- Input as mechanical power.

Pconv= tindwm

- Output power is given here.

Pconv=EAIA

- But, this is not the power that gets at the output terminals. Before reaching at the output terminal copper losses and brush losses also subtracted from it.

- In the given figure the dc motor power flow diagram is given it is the reverse of dc generator power flow figure.

Related Article

- You can aslo read some related posts.

- Introduction to DC Machines

- What is Armature Reaction

- Construction of DC Machines

- Internal Generated voltage and torque of DC machines

- Methods of Improving Commutation

- Wave Winding

- Commutation Problems In DC Machines

- Lap Winding in DC Machines

- Commutation and Armature Construction In DC Machines

- Commutation in Four Loop DC Machines

- Rotating Loop between Curved poles

So that is the detailed post on the Power Flow and Losses in DC Machines, I have written each and every parameter related to the Power Flow and Losses in DC Machines. If you have any query ask in comments. See you in the next tutorial. Thanks for reading.