Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at the Construction of DC Machines. In our electrical system, there are 2 main types of machines first one is AC machines that are further divided into ac motors like synchronous motor, induction motors, single-phase induction motor, three-phase induction motors and in generators like a synchronous generator and induction generator. The second type of machine is dc machines that are also divided into dc motors, dc generators, and these are further divided into shunt motors, shunt generators, series motors, and series generators.

Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at the Construction of DC Machines. In our electrical system, there are 2 main types of machines first one is AC machines that are further divided into ac motors like synchronous motor, induction motors, single-phase induction motor, three-phase induction motors and in generators like a synchronous generator and induction generator. The second type of machine is dc machines that are also divided into dc motors, dc generators, and these are further divided into shunt motors, shunt generators, series motors, and series generators.

Both of these two machines either DC or AC are play a very important role in our electrical power system. AC machines is used in our generation system while the dc machines are used in drill machines, trains, robotics, etc. In today’s post, we will have a look at the construction of the dc machine and will explain it’s every part with detail. So let’s get started with the Construction of DC Machines.

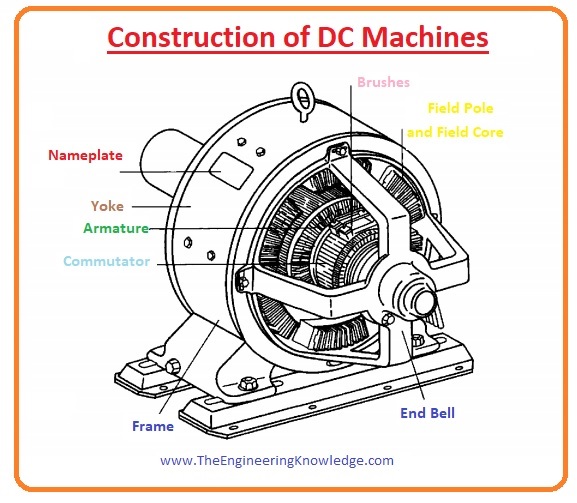

Construction of DC Machines

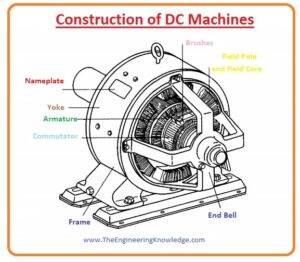

- In the structure of DC machine either dc motor or generator, there are 2 main parts first one is static or the second one is moving. The static part is stator and the moving part is rotor.

- In the stator of dc machine, there is a frame that provides protection and support to the internal structure from the external environment, in this frame, there are poles that produce field at the stator.

- The part of pole that is close to rotor distributes the flux on the surface of the rotor is known as pole shoes.

- The surface of pole in front of rotor is known as the pole face and the space between the rotor and pole face is known as an air gap.

- There are 2 main types of windings that are wound on these machines first one is field windings that are wound on stator and the second one is armature winding that wound on rotor.

- Friends, now we discuss all parts of dc machines with the detail.

DC Machine Pole and Frame

- The pole of the earlier dc machine at the stator was constructed by cast metallic material and having stator (field) winding wound on it.

- Tips of these poles were insulated with the insulating material to the eliminate of core losses at the faces of the poles.

- Nowadays solid-state drive is mostly used so poles of dc machines are construed with the insulating material (insulated).

- The use of these high lamination poles in machines reduces the eddy current losses.

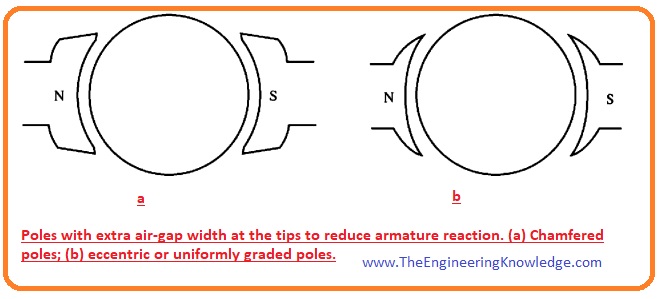

- The faces of poles are generally eccentric in design, it means that the outward part of a pole face is spread out slightly away from the surface of the rotor than the midpoint of the pole face as you can see in this given figure.

- This design technique enhances the reluctance at the outward part of a pole face and so decreases the flux-weakening effect of armature reaction.

- The poles at the stator of dc machine are known as salient poles, as they can remove from the stator.

- The locations of interpolates that are used to reduce the armature reaction in-between the main poles at the stator they are also laminated with the insulated because in these poles losses are similar to main poles.

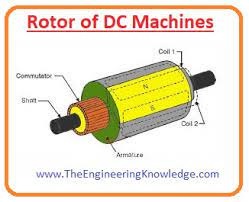

Rotor of DC Machines

- The rotor of dc machines comprises of the shaft manufactured with the steel and core assembled on this shaft.

- The core consists of numerous laminated sheets of steel plate that have some cuts to arrange the armature windings.

- At the end of the shaft commutator is fixed for the conversion of AC into DC and armature windings are connected with them.

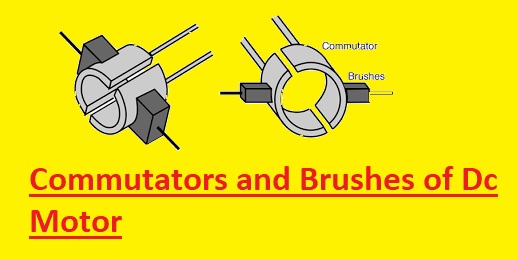

DC Machines Commutator and Brushes

- The commutator in dc machines are constructed with the copper and laminated with mica.

- The copper bars have a high thickness to work longer time almost running life of machine.

- The mica protection among commutators is more solid than the commutator substantial itself, therefor with the passage of time, it is essential to remove the commutator lamination to confirm that it does not stick up rotor bars.

- The brushes of dc machines are connected with the commutators and are constructed with the carbon, graphite or with the mixture of graphite and carbon.

- Due to their best conductive behavior, they minimize electrical losses and have less coefficient of friction.

- They are normally constructed with the softer material than the material used for commutators so there is no need of special protection at the commutators.

- The hardness of the brush should be medium if they are too soft than will damage after some time and should be replaced and if hard will affect the commutators.

DC Machines Winding Insulation

- The most sensitive part of dc machines is winding insulations. If windings are not properly wound or damage due to some certain reasons then windings of machines will be short-circuited.

- The maintenance of a machine after a short circuit is very costly some time it is not possible to repair it we have to buy new windings.

- To increase the life of winding insulation there is a need to decrease the temperature of winding. The temperature of a machine can be decreased by providing cool air to a machine but the main factor that controls heating is the power provided to the machine.

- Insulation infrequently damages from instant failure at some dangerous temperature. In its place, the upsurge in temperature generates a slow ruin of the insulation, making it subject to damage due to shock, vibration, or electrical stress.

- As we listen that motor life remains half with each ten Celsius increment in temperature this rule is true and applicable on the machine.

So friends that is the detailed post on the construction of DC machines if you have any questions ask in the comments. See you in the next comments.