Hello, fellows, I hope all of you are having fun in your life. In today’s tutorial, we will have a look at the Methods of Improving Commutation. In DC machine the commutation is a very important process, through which alternating current production in machines is converted into DC at the output terminals. For this process, commutator segments are placed at the rotor of dc machines that converts ac into dc. During this commutation there some problems occur that we discussed in detail in the previous tutorial of commutation problems, the first one armature reaction and the second one is L di/dt voltages.

Hello, fellows, I hope all of you are having fun in your life. In today’s tutorial, we will have a look at the Methods of Improving Commutation. In DC machine the commutation is a very important process, through which alternating current production in machines is converted into DC at the output terminals. For this process, commutator segments are placed at the rotor of dc machines that converts ac into dc. During this commutation there some problems occur that we discussed in detail in the previous tutorial of commutation problems, the first one armature reaction and the second one is L di/dt voltages.

These two issues severely affect the commutation process. In this tutorial, we will discuss the solution of these issues that occurs with the commutation. So let’s get started with the Solutions to the Problems with Commutation.

Methods of Improving Commutation

- To solve the problems of commutation armature reaction and L di/dt there are these three main techniques are used, that are listed here.

- Brush shifting.

- Commutating poles or interpoles.

- Compensating windings.

- Let’s discuss these 3 techniques with the detailed.

Brush Shifting

- First time the effort was done to make some improvement in the commutation process was initiated with to decrease the flashing occur at the brush due to neutral plane shift and L di/dt voltages.

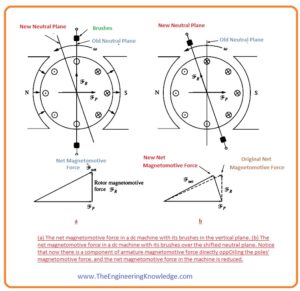

- To solve these issues that times engineers thought that with the variation in the position of neutral plane (the neutral plane is the position where the rotor of machine is rotating parallel to the magnetic flux lines, that is why an axis lying in this plane is known as magnetic neutral axis (MNA)) shift there should also change the position of carbon brushes.

- It looks a good option but it also creates some problems. The neutral plane changes its position with the load variation if our machine is dc motor due to some certain load variation it behaves like a generator.

- Then we have to higher a man on the machine to adjust the location of the position of brushes as the neutral plane changes according to load variation.

- Let’s suppose that if we vary the position of brushes according to the neutral plan shift it might decrease the flashing at the brushes, nevertheless it increases the flux-weakening effect of the armature reaction in the machine.

- It is correct due to these two factors.

- The vector element of mmf at the rotor opposes the mmf of the poles of machines. You can see this in a given figure.

- The variation in armature current spreading origins the flux to bunch up larger the saturation portion of poles.

- Additional somewhat different method occasionally taken was to fix the brushes at a compromising location (it means no flashing occurs at 2/3 of full load).

- In this situation, the motor flashed at zero load condition and slightly at full load, but if it consumed furthermost of its life functioning at around 2/3 of full load, then flashing was lessened.

- Such a machine cannot operate as a generator, the flashing can cause a serious disaster.

- After 1910, the brush shifting technique for the reduction of flashing has been eliminated.

- Nowadays this method is only used for dc motor of small rating, not for generators. For these motors, this technique is less expensive than others.

Commutating Poles or Interpoles

- As we discussed above that a permanent magnet needs to change the position of the carbon brushes with the load variation, there is another solution to this issue that we eliminate the voltage in the conductor that doing commutation. In this way, flashing will be decreased.

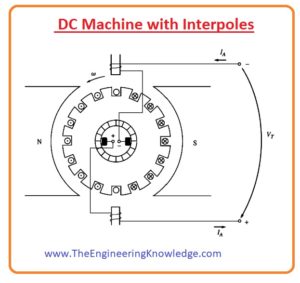

- To do this small pole that is known as interpoles or commutating poles are introduced among the main poles of the machine.

- These small poles are connected with the wire that is using in the commutation process. These small poles have their own flux, this flux will interact with the conductor flux in such a way that it will minimize the effect of the flux of the conductor.

- In this way, flashing can be decreased at commutator segments. One question will come to your mind that either these small poles also affect the operation of a machine.

- Certainly, not these poles and their flux do not affect the operation of the machine they are smaller size and their flux strength is so less that it only affects some conductors that are doing commutation.

- You can note that these small poles are not effecting the flux weakening effect caused by the armature reaction simply we can see that these small poles only reduce the flashing occurring on the commutators, not the armature reactions.

How is annulment of the voltage in the commutator segments generated for all values of loads?

- For this there is another winding called interpoles winding is connected with the armature winding of the machine. It is shown in this given figure.

- With the increment in load attached with the machine armature current also increases, with that shifting of a neutral plane and L di/dt voltage also increases.

- These 2 factors also increase the voltages of conductive wires that are taking part in the commutation process.

- The flux of interpoles also increases that that decreases the effect of the voltage caused by the shifting of a neutral plane.

- The final outcome is that their effects cancel over a wide range of loads. You can see that interpoles or commutation poles operate for both motor and generator operation, as when the machine alters from motor to generator, the direction of current in its armature winding and interpoles also changes.

What is the polarity of Interpol’s flux?

- As the interpoles are linked with the conductor that is using in commutation process its voltage direction is reverse to the voltages caused by the neutral plane shifting and L di/dt.

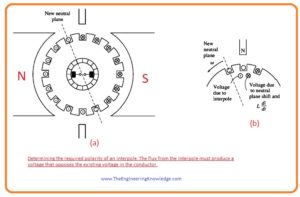

- If our machine is generator, as we have known that in the generator the shifting of direction of neutral plane is in that direction in which rotor is rotating. You can see it in the given figure.

- It means that the wire that is using in the commutation process have a similar polarity of voltage as the pole they left behind.

- To decrease the effect of these voltages the polarity of interpoles flux should be opposite.

- In case of motor, the shifting of neutral plane is opposite to the direction of rotation of rotor and the

- In a motor, however, the neutral plane shifts opposite to the direction of rotation, and the flux of conductors taking part in the commutation have similar polarity to the pole towards that it moving.

- For decreasing the effect of this flux the polarity of the interpoles flux is similar to polarity as the previous main pole.

- So we can say that,

- The polarity of interpoles in case of a generator is similar to the next upcoming main pole.

- WHILE in case of motor the polarity of interpoles should be equal to the polarity of previous main pole.

- The practical implementation of interpoles nowadays is very common because it is the less expensive solution of reducing the flashing at the commutators.

- You can see these poles in almost every dc machine of one horsepower or larger.

- One important thing you must know that this pole has no effect flux scattering under the pole faces, therefor weakening of flux is still exits.

- Mostly intermediate size, motors use interpoles for flashing or sparking problems with them leaving the weakening of flux in the machine.

Compensating Windings

- For severe duty cycle motors, the flux weakening effect that caused by the armature reaction can create a serious problem.

- To entirely eliminate the armature reaction and also elimination of flux weakening and neutral plane shifting numerous methods have been introduced. Like interpoles and brush shifting that we have discussed.

- There is another method to solve these issues of dc machines place another winding on the poles parallel to the rotor called compensating winding. These windings minimize the effect of armature winding.

- This compensating winding is attached with the armature winding in series, with the variation in load armature current changes that also vary the value of current in the compensating winding.

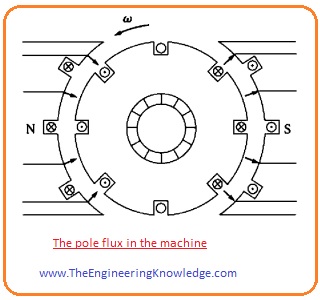

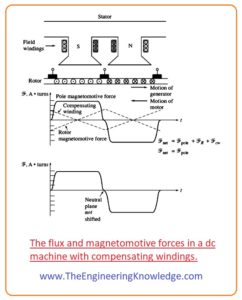

- In this given below the figure, you can see the flux of poles.

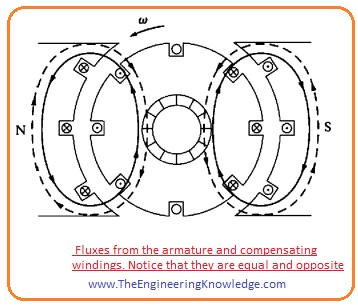

- In this below figure you can see that the flux of armature winding at the rotor and flux of the compensating winding.

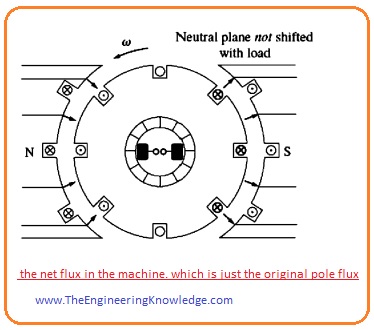

- In this below figure, you can see that the addition of pole flux, armature winding flux, and compensating winding flux that is equivalent to the flux of pole.

- The given below figure explains the detailed effect of compensating winding in dc machines.

- You can see that mmf caused by the compensating winding is equivalent and opposite to the mmf of rotor at each point under the effect of poles.

- The resultant net mmf is the mmf due to the poles, so the flux in the machine is unaffected irrespective of variation in load attached with the machine.

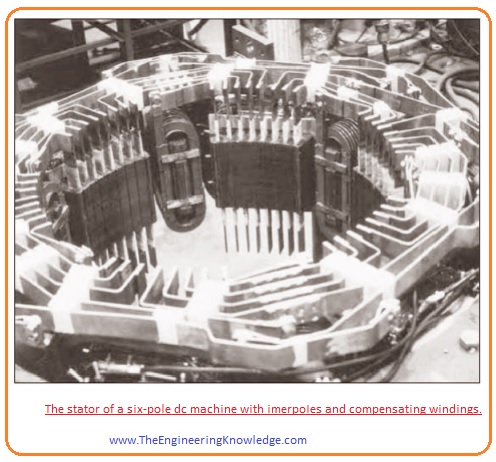

- In this given figure you can see that the stator of a larger rating dc machine with compensating windings is shown.

Disadvantage of Compansating winding

- The main drawback of compensating is that its cost is very high, as its locations are always should in front of poles of the machine.

- The dc motor should have interpoles, as compensating winding do no minimize the L di/dt effects.

- The strength of interpoles should not be as high, however, as they are minimizing only L di/dt voltages and not the voltages caused by the shifting of the plane.

- The use of both the interpole and compensating winding in machine makes it too much expensive, so these windings are used only where the tremendously severe nature of a motor’s duty asks for them.

So friends that is the detailed tutorial on the Methods of Improving Commutation I have mentioned each and every parameter related Method of Improving Commutation. If you have any questions about this post ask in comments. See you in the next tutorial.

In your article title “Methods of Improving Commutation”, section “What is the polarity of Interpol’s flux?”, there’s one incomplete sentence:

In case of motor, the shifting of neutral plane is opposite to the direction of rotation of rotor and the…

Please provide the missing words.

Many thanks for your excellent article!

Best regards,

Hoai

thanks dear

I have completed missing words