In the era of rapid industrialization, businesses are constantly seeking methods to enhance their operational efficiency. Traditionally, heavy-duty handling was labor-intensive, often resulting in significant delays and safety hazards.

Faced with these challenges, the industry is increasingly leaning towards technologically advanced solutions. Enter the realm of powered casters: a revolution that promises to streamline workflows and elevate safety standards. These innovations are like the best essay writing services for industrial efficiency, ensuring a smoother and more productive path for businesses.

What Will You Learn?

In this blog, we’re about to explore the revolutionary world of powered casters, a technology that is changing the face of industrial operations. Let’s unravel the secrets that could transform your industrial operations.

Understanding Motor Powered Caster: The Basics

In the bustling industry world, introducing the powered caster might be the game-changer we’ve been waiting for. Let’s break down why.

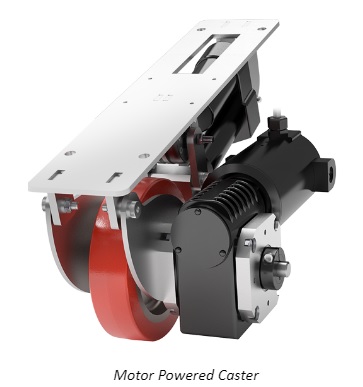

At its core, a powered caster is an advanced tool designed to propel heavy-duty movement with ease. Think of it as the muscle behind pushing weighty objects effortlessly.

Wondering about its capabilities?

These casters can move an impressive 5,000 lbs and hold up to 2,000 lbs. Powered by a half-horsepower motor, it can reach speeds up to 2MPH. The resilient polyurethane wheel, backed by a cast iron core, ensures durability. All this strength is encased in robust steel with a finish that stands the test of time.

Meet the industry’s pioneer: the Drive Caster.

This trademark innovation is more than just equipment; it’s a pathway to seamless, profitable operations. The Drive Caster, adaptable as a Drive Cart, has practically obliterated manual pushing and pulling, simplifying material transport remarkably. Imagine the ease of shifting up to 10,000 lbs. and the flexibility to engage or disengage the motor, enhancing speed and efficiency manifold.

Features of Motor Powered Casters

Diving deeper into the motor-powered caster universe, we come across some standout features that make these tools incredibly compelling.

Firstly, the impressive robustness is specially crafted for challenging heavy-duty tasks. This isn’t just another caster; it’s a behemoth designed to handle intense loads.

Depending on the motor choice – the 1/4hp or the powerful 1/2hp – the caster can effortlessly shift between moving a substantial 3,000 lbs. load to a whopping 6,000 lbs. without a hiccup.

Advance Features:

Advanced controls in the caster ensure that your goods are always in safe hands (or wheels!). These controls, coupled with optional encoders, allow users to monitor speed, measure distance, and even gather feedback for automation. It’s like having an intelligent assistant on your factory floor!

There’s an eco-friendly feather in its cap, too. The rechargeable batteries in these casters reduce reliance on fossil fuels, paving the way for a greener industrial landscape. are the best option for every industry’s supplies mo

What about its synergy with other equipment?

The electric Industrial wheels for carts perfectly match powered casters, enhancing their utility manifold.

Advantages of Motor-Powered Casters in Industrial Settings:

Integrating motor-powered casters can be the gateway to exponential growth in an industrial setup where time equals money. Let’s delve into these casters’ numerous advantages, promising a future where efficiency meets innovation.

-

Efficiency Takes Center Stage:

The times of laboriously pushing and pulling heavy loads are fading. Drive Caster wheels have transformed the game, enabling rapid movement that traditionally took twice the time.

Picture this: an operator smoothly starting, navigating, and halting a load with a mere control panel, and you’ll understand the newfound efficiency. With capacities to support 2000 pounds in general scenarios and an impressive 5000 pounds when towing, the difference is clear.

-

Safety: A Top Priority:

The design of powered casters, like Drive Caster, shines brightest in tight spaces. Precise maneuverability ensures safety isn’t compromised, even in the most delicate operations. The reduced manual effort cuts down fatigue and minimizes injury risks.

-

Cost Effectiveness:

Longevity in machinery isn’t just about endurance but also smart technology. With lesser wear and tear, the infrastructure and machines stand the test of time, ensuring long-term benefits.

Furthermore, imagine the labor costs saved when one operator can seamlessly replace the work of several manual pushers. The versatility of motor-powered casters are worth noting, integrating effortlessly into diverse applications, from industrial carts to turntables and platforms.

Challenges and Solutions in Implementing Powered Caster Systems:

Every great innovation presents challenges, and the powered caster systems are no exception. But, as with all things technical and groundbreaking, the solutions are often rooted in understanding and foresight.

-

Initial Investment Cost:

Adapting to the future is rarely without cost. Transitioning to drive caster wheels and the broader powered material handling cart systems requires an initial investment. It’s natural to be cautious, especially with upfront expenses.

The Solution:

Consider it from a broader perspective. Shifting to powered caster systems is not merely an expense but an investment. With the longevity and efficiency they bring, there’s a promising ROI.

Over time, the operational costs dip, machinery maintenance slackens, and productivity soars. Financial foresight reveals that these systems, although requiring a starting investment, offer returns that traditional systems might never match.

-

Training and Adaptation:

Introducing novel systems means your workforce needs to adapt. Training becomes paramount, and the learning curve might appear steep.

The Solution:

Fortunately, the essence of these systems lies in their simplicity. Designers and engineers have crafted these casters to be user-friendly. With easy controls and intuitive features, staff adaptation is quicker than anticipated.

Moreover, dedicated training modules further ease the transition, ensuring your team is confident and skilled in handling the new equipment.

The Future of Heavy-Duty Handling: Predictions and Trends:

The horizon of heavy-duty handling is expanding rapidly, and with it emerges a new paradigm.

-

Automation’s Rise:

Imagine powered material handling cart systems, where tasks once demanding manual oversight become automated. Swift, efficient, and flawless – that’s the promise of the coming age.

-

Smart Tech Fusion:

Tomorrow’s electric industrial carts won’t just be powered; they’ll be intelligent. Integrated with innovative technologies, they’ll offer unmatched precision, adjusting in real-time to the demands of the environment.

-

Humans: Supervisors, Not Laborers:

The future might see fewer hands lifting weights but more minds innovating. Human operators will shift from mere handlers to crucial decision-makers and overseers in these powered material-handling cart systems.

Conclusion:

As we draw to a close, let’s retrace our journey into the vibrant world of powered caster systems. These game-changers have genuinely begun a revolutionary chapter in heavy-duty handling.

Industries stand on the cusp of an exciting era; a shift towards these systems is not just beneficial, it’s pivotal. We urge entities to lean into the future, embracing the myriad long-term benefits that powered caster technology and electric industrial carts bring to the table.

Join the Movement:

If you’re interested in what we’ve developed at Conceptual Innovations (conceptual-innovations.com), get in touch. Contact us to delve deeper into our groundbreaking drive caster wheels solutions and explore how they can propel your business into a new dimension of efficiency and productivity.