Hello, fellows, I hope all of you are having fun in your life. In today’s tutorial, we will have a look at the Induction Motor Design. In 1880 Nicola Tesla (who was an American Engineer) gave the basic principles of the induction motor, in 1888 due to his ideas on the induction motor he received a patent. He offered the paper to the American Institute of Electrical Engineer in which he explained the working principle of the wound rotor induction motor. He also explained the working principles of the synchronous motor and reluctance motor.

Hello, fellows, I hope all of you are having fun in your life. In today’s tutorial, we will have a look at the Induction Motor Design. In 1880 Nicola Tesla (who was an American Engineer) gave the basic principles of the induction motor, in 1888 due to his ideas on the induction motor he received a patent. He offered the paper to the American Institute of Electrical Engineer in which he explained the working principle of the wound rotor induction motor. He also explained the working principles of the synchronous motor and reluctance motor.

Though the elementary knowledge of the induction motor as defined in 1888, the motor itself did not spring forth in the complete arrangement. There was an early era of fast progress, followed by a sequence of sluggish, evolutionary developments that have continued to this day. So let’s get started with Induction Motor Design.

Induction Motor Design

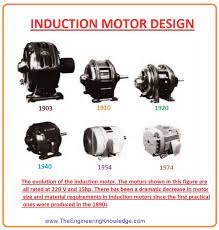

- The induction motor was presumed familiar up-to-date form between 1888 and 1895.

- During this time interval, 2 and 3-phase energy sources (supplies) were invented to generate a revolving magnetic field in the motor.

- With the two and three phases there were also invented distributed winding and cage rotor design rotors of the motor.

- In 1896 complete constructed 3-phase induction motors were available to the markets for commercial use.

- After 1896 and till the starting days of 1970, the best quality steel was introduced to the market, with which different casting methods, insulating materials,s and different construction specifications of induction motors were developed.

- By using these new parameters such motors were developed that cost-effective, smaller-size motors that produced desired output power were introduced to the world.

- Today’s hundred horsepower motor has a similar construction like the 7.5 horsepower motor that used in 1897.

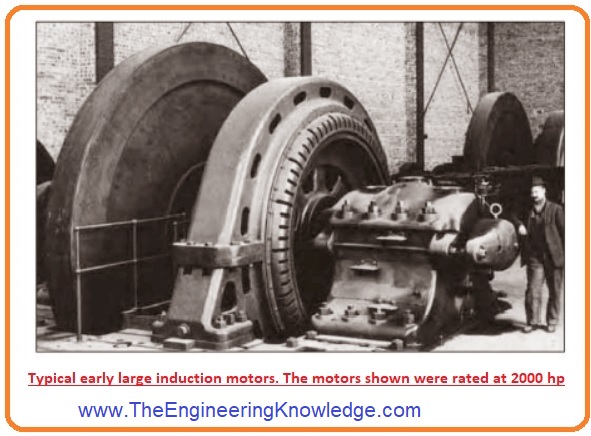

- This development is demonstrated for fifteen horsepower motors in the given figure.

- See also this figure that shows the two thousand horsepower motor that used in previous years.

- Though, these developments in induction motor designing did not essentially lead to enhancements in motor functioning efficiency.

- The main design changing was leading to decreasing the original materials price of the motors, not to enhancing their efficiency.

- The design exertion was oriented in that direction as the price of electrical energy was higher, creation the up-front price of a motor the main standard used by buyers in its choice.

- Meanwhile, the expense of oil began its remarkable rise in 1973, the lifetime functioning price of motors has become very important, and the fitting price has become comparatively less significant.

- As a consequence of these parameters, new stress has been employed on motor efficiency both by engineers and by consumers of the motors.

How to Improve the Efficiency of Induction Motor

- There are some methods used to increase the efficiency of the induction motor.

- Larger no of the turns should be used in the stator for the reduction of the copper or I2R losses.

- The reduction of the losses at core increases the length of stator and rotor cores it will reduce the flux losses in the air gap of the motor.

- A large amount of stator used in the stating part (stator) of the motor, it will help to remove heat produced in the motor and due heat removal motor temperature will not increase. For the reduction of the windage losses, the motor fan is connected to the rotor.

- The steel of the stator should be high quality so it can easily magnetize and demagnetize in this way there will be fewer hysteresis losses.

- The steel is prepared of a particularly thin scale which means the laminations are very close to each other and the steel provides larger inner resistivity. These properties decrease the eddy current losses in the motor.

- The rotor is wisely designed to make a constant air-gap, it will decrease the stray losses of the motor.

- With these above mention methods, every manufacturing company has its own methods for the increment of the efficiency of the motor.

- A distinctive higher efficiency induction motor is shown in Figure.

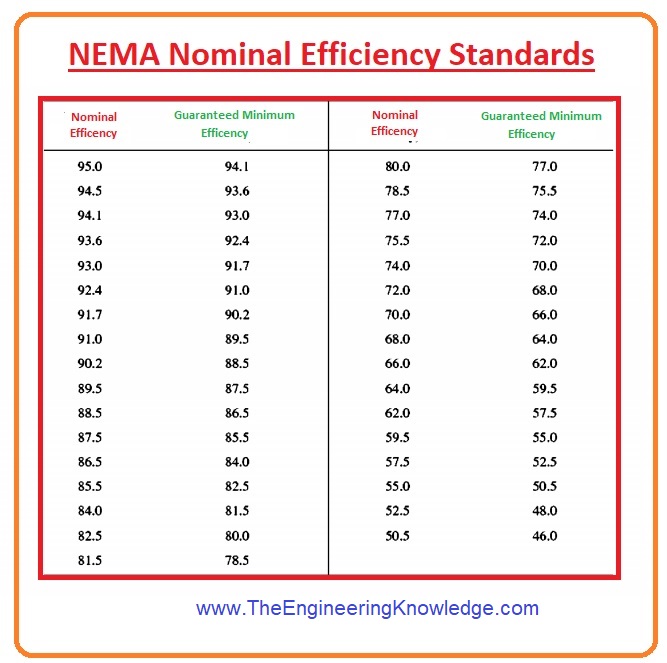

- To help in the relationship of motor efficiencies, NEMA (National Electrical Manufacturers Association) has implemented standard methods for determining motor efficiency based on technique B of the IEEE (Institute of Electrical and Electronics Engineers) Standard 112, Test Process for Poly-phase Induction Motors and Generators.

- NEMA (National Electrical Manufacturers Association) has also presented a rating known as NEMA (National Electrical Manufacturers Association) nominal efficiency, that mentioned on the name-plates of design class A, B, and C motors.

- The nominal efficiency defines the average efficiency of a larger no of motors of a specified model, and it also assurances a specific lowest efficiency for that kind of motor.

- The given diagram shows the standard NEMA (National Electrical Manufacturers Association) nominal efficiencies.

- Other standards groups have also recognized efficiency parameters for induction motors, the significant of that are the British (BS-269), IEC (IEC 34-2), and Japanese (JEC-37) standards.

- Though, the methods approved for determining induction motor efficiency are dissimilar in every standard and give different outcomes for a similar physical structure motor.

- If 2 motors have 82.5 % efficiency, but they are defined according to dissimilar standards, then they cannot be correspondingly proficient.

- When 2 motors are compared, it is vital to relate efficiencies found according to a similar standard.

It is the complete article on the Induction Motor Design if you have any questions about it ask in comments. Take until the next tutorial, starting method of induction motor.

You can also read some related articles to the induction motor. That is described here.

- Introduction to Induction Motor

- Introduction to Three Phase Induction Motor

- Equivalent Circuit Induction Motor

- Induction Motor Torque-Speed Characteristics

- Variations in Induction Motor Torque-Speed Characteristics

- Power and Torque in Induction Motors

- Induction Motor Design Classes

- speed Control Method of Induction Motors