Hi guys welcome to the new post. Here we will discuss What is Circle Diagram of Induction Motor – Definition, Construction, and its Parts. In the electrical engineering world, the circle diagram of the induction motor is the main parameter that is used to study and analyze the working of this device. In this post, we will discuss different parameters for a circle diagram. So let’s get started with What is Circle Diagram of Induction Motor.

Understanding Induction Motors

These motors are used in different applications from small house uses to heavy industries due to their reliability and effective structure. They work on the electromagnetic induction principle where a rotating field induces a current in the rotor and the rotor moves

What is a Circle Diagram of an Induction Motor?

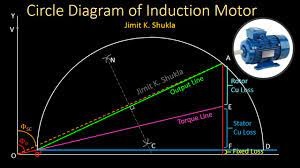

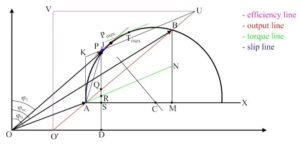

A circle diagram of an induction motor is a graphical denotation of the motor working. It is a good factor in getting about motor working in different load conditions. The current phasors are made like a radius from the origin point, and the voltage phasor is as the diameter of the circle. The angle between two phasors is the power factor angle of the motor.

The circle diagram is used to find different parameters, such as

- Motor output power

- Motor losses

- efficiency of the motor

- Highest torque that the motor can produce

- The slip of the motor

Parts of the circle diagram of an induction motor

- Stator voltage phasor: It is the phasor denotation of voltage given to start of motor

- Stator current phasor: It does curent in the stator winding of the motor

- The power factor angle is the angle between the stator voltage phasor and the current phasor. It is a measurement of how effectively a motor is transforming power into mechanical power.

- Losses: These are the losses in the motor, such as copper and iron losses. The shaded area in the circle diagram represents them.

- Efficiency: It is the ratio of output power to input power. It is shown with the percentage of shaded area covered with stator current and voltage phasor.

- Output power: The mechanical output power of the motor. Dentoed through an area covered by stator current phasor and voltage phasor.

- Slip: It is the difference between the synchronous speed of the motor and the actual motor speed. It is denoted by the distance between the stator current phasor and origin point

What is Slip Ring, Types Working, Applications

Read also: DC Motor Starters and Circuit Diagram

Construction of Circle Diagram of Induction Motor

A circle diagram is made with stator current with stator volts, with voltage between two phasors as parameters. The circle garage is used for measuring the parameters of the induction motor.

- No-load current

- Blocked rotor current

- Torque

- Efficiency

- Slip

- Power factor

Follow these steps to make the circle diagram of an induction motor:

- Draw a vertical line that denotes rated stator volts V1

- Select the best scale for the curent

- OB line for lagging V1 by angle ΦSC equal to blocked rotor current for normal volts.

- Connect AB with the output line of the rotor.

- Ninety degrees bisector to line AB connecting horizontal line AX at point C

- The join line from O to C denotes air gap power.

- Line B to F that is BF in parallel to V1 used for copper losses

- Line FG parallel to V1 denoted stator copper losses

- The area covered by the curve OABFCG is the output power of the motor.

Significance of lines on the Circle Diagram

The different lines on the circle diagram have this significance:

- Input line: It shows input power to the motor. The vertical distance between any point of a circle and a line on is the input power of the motor.

- Output line: It is used for the motor’s output power. Distance between any point of the circle and O’F denotes the motor’s output power at that operating point.

- Slip line: It denotes the slip of the motor. Slip is the difference between the rotor speed and the synchronous speed.

- Power factor line: This line defines the motor’s power factor. The power factor is the ratio of the real power to the apparent power.

- An air gap power line is used for the air gap power of the motor. The air gap power is used to drive the rotor of the motor.

- Torque line: This line shows the motor’s torque. The torque is the force that the motor gives to the load.

The circle diagram can be used to determine the following points:

- The maximum output power of the motor

- The maximum torque of the motor

- The operating point at which the motor has maximum efficiency

- The operating point at which the motor has minimum losses

- The effect of varies in the supply voltage or frequency on the motor’s performance.

FAQs

What is a circle diagram in induction motors?

The circle diagram is the graphical representation of the operation of an electrical machine drawn in from of the locus of the machine’s input voltage and current. .

How to draw circle diagram of single-phase induction motor?

The circle diagram of a single phase induction motor is more complicated than that of a three-phase induction motor. This is because the single-phase motor has a pulsating magnetic field, which makes it challenging to analyze. But, some methods can be used to draw the circle diagram of a single-phase induction motor.

One is to use the equivalent circuit of the motor. The equivalent circuit is a simplified representation of the motor that can be used to measure motor operation performance. When the equivalent circuit has been made, the circle diagram can be drawn by plotting the input voltage and current of the motor.

The second method for drawing the circle diagram of a single-phase induction motor is to use a computer simulation. Computer simulations can be used to correctly calculate the performance of the motor under different conditions.

What is 3 3-phase slip ring induction motor?

A three-phase slip ring induction motor is an induction motor that has a rotating shaft. it is a variation of a phase induction motor, made to offer high starting torque with low inertia, while needing low starting current

Is the induction motor AC or DC?

Induction motors are AC motors. They require an alternating current supply to operate.

What is induction motor principle?

is a working principle based on electromagnetic induction . Electromagnetic induction is the phenomenon in which the EMF is produced when conductors are placed in a rotating magnetic field.

Why it is called an induction motor?

The induction motor is called an induction motor because the stator magnetic field induces the rotor current. An external source, like a DC motor, does not provide the rotor current.

What is torque of a motor?

The torque motor is the amount of rotational force that rotates motor. For small motors, it measured in inch-pounds (in-lbs),

What is induction motor types?

Single-phase induction motors and three-phase induction motors are the main types of induction motors

What is a 3-phase motor?

A three-phase motor is a motor that is powered by a three-phase electrical supply. Three-phase motors are more effective than single-phase motors and can give more power.

What is the DOL starter?

Direct on line (DOL) motor starting is if the motor is started at full load with full line voltage provided to motor terminals.

What is stator and rotor?

The stator is the static part of ac motor, and the rotor is the rotation component of the motor.