SONY DSC

Hell readers I hope you all are enjoying your life. In this post, we will learn How to Manufacturer PCB Board. PCB board is the very basic component of each and every electronic device and electronic project that is created or constructed in any field of engineering. So the proper working and construction of any PCB board is needed in a proper way so our project work accurately and properly since its main requirement is to work effectively.

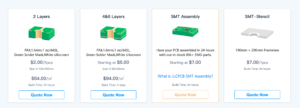

In this post, we will learn how we can make our PCB for project simulation. If you are new and has little knowledge of PCB construction here i want to mention that you can get the services of different PCB manufacturer but I want to suggest the best PCB supplier and manufacturer that make PCBs at the proper level and best prices with good quality that are easily getting by any users and will also learn how PCB manufactured in JLCPCB. This PCB supplier is JLCPCB. It is china based PCB supplier that is offering PCB services for the last fifteen years all over the world. They never compromise the quality and best services that you needed. Their main services are related to PCB, PCB prototyping with that different types of boards like single-sided, double-sided, multiple-sided PCBs etc. JLCPCB continuously driven to become more efficient and reduce costs. they promise to offer customers the most economic PCBs forever. They are constantly looking for new ways to improve and shorten the PCB prototyping process from pioneering online quoting system, automatic production to fast delivery. Almost more than three thousand employees consisting of engineers and other staff is working in their industries. Some interesting offers offered by the JLCPCB are shown in below figure. So let get started How to Manufacturer PCB Board.

How to Manufacturer PCB Board

- There are some steps needed to make PCB that is explained here with the details.

PCB Film Design

- When any customer sends the Gerber file to the JLCPCB their engineer review that file and come to know that either it is ready to make PCB or has to amend it.

- file gets accepted this design is created through the use of photoplotters and created in the photomasks in a certain value of temperature.

- info is given in the Gerber gets by the photoplotter and transforms into image form.

- It is a film that is sent for manufacturing procedure.

Material Cutting for PCB

- In this step the material that will be used for PCB construction is FR4 used in different ranges of thickness like 0.4, 0.6, 1.2, etc and has copper sheet covered at its both sides working as lamination.

Drilling Process

- In this process, holes are created through the use of drilling through which components lead passed and connection will be made.

For the accuracy of holes at the boards, there is some additional holes are made at the corners of boards.

The drilling machine is software operated different software is used to design the holes according to PCB configuration.

In the factories of JLCPCB, there are almost seventy drill machines available.

Copper Placement

When drilling is completed then an electroless deposition procedure is employed that helps to place the copper at the board and make different layers of copper that will help to the movement of current in the project that will be created on it.

There is plated through holes are used to make connections conductive elements placed in the copper layers.

External Layer Imaging

This procedure also called dry film etching where the board is covered with a thin sheet of material called photosensitive etch resist.

After this board is placed in areas where UV light falls on it.

The UV light will make strict the photoresist placed at the board.

Additional resist element is removed from the board and the board is placed in the high temperature where the operation time of other resistant material increases.

Plating Process

For increment in the copper thickness that lies at the board and about the holes, there is plating process is done on the board. There is a layer of tin is placed at the board through plating.

When the plating is finished resist element is completely removed and just copper layers, pads, and plated layer remains at the board.

Etching Process

In the etching process, the additional copper that exists at the board is removed and not affect the plated area.

After that plating is removed with use of the solution of chemical substance and just remained the copper layers pads and holes at the board.

Automated Optical Inspection

It is a visual inspection technique that used to finds the different faults occur at the board and areas where resist element get removed with the force and made a scratch.

These types of errors can not be removed through continuity tests. In the visual inspection technique, there is the usage of the laser.

Solder Mask Usage

To provide protection to the boards from the external environment and harsh conditions there is the employment of solder MASK on the board.

Its normal colors are blue, red, white and yellow.

Silkscreen

Silkscreen is very useful for users to get the proper knowledge about the layout of elements that are employed at the board.

In this process, there is numerical numbers, alphabetical letters, date of creation, and features of components are mentioned at the board.

Silkscreen can be employed at the lower part of the board.

Surface Finishing

In this process, PCB is get plated through the use of electroless gold over nickel. It has two benefits first one is to provide protection to the copper to get corrosion and the second one is offering a solderable area to position the circuit components.

Profiling Process

In this process there is certain shape is given to the board through the use of a machine operated with the computer.

There is a smooth corner is given through this process. There is the usage of V cutting for isolation of board.

There is the use of a cutting device for the creation of a V form line at the board. It helps to board snapped out.

Electric Testing of board

An electrical test is done on the board to finds any fault or open circuit in the board and there is short circuit exist.

Final Inspection

When the board is completed at the JLCPCB there is final review is done to check either all requirements of customers exist in the board and there is no fault exist in the board. THen board is sent to the customer.

That is all about the How to Manufacturer PCB Board I tried to cover the all steps involved in the PCB manufacturer if you have any query ask in the comments. Thanks for reading have a nice day.