Hello, readers welcome to the new post. Here we will discuss JLCPCB PCB ASSEMBLY and 54$ COUPON. JLCPCB is the best quality services provide related to PCB board and electronic manufacturing that carrying its standard PCBA services as the main project launched by JLCPCB is committed to decreasing the pricing of PCBA services, improving the ordering process, increasing the speed of SMT lead time, thus providing professional electronics engineers to focus on their an electronics business that enables industrial companies to produce high-quality electronic products.

The SMT services of JLCPCB were introduced in 2019, but the base of this project started in 2016 and it has been stable for the last decade. JLCPCB is an experienced and expert SMT industry and manufacturer. Component angle is an industry problem that affects SMT. JLCPCB was one of the first manufacturers to stand out and popularize the standard. The latest IPC-7351C can also followed this standard.

JLCPCB makes every effort to improve its products, services, and processes to meet or exceed our customers’ expectations. To promise customers the highest quality products and services, their quality commitment policy is driven by continuous improvement in product innovation, proactive monitoring of quality and reliability, and increasing overall customer satisfaction.

JLCPCB Global Parts Sourcing Service

- The creation of a parts library by JLCPCB parts pre-order features was launched in 2021 and after that service, they launched the global sourcing service in 2022 which is an innovation for the PCB industry and assembly. The creation and assembly of more than a hundred pieces is a very difficult process and industry. That results in chip manufacturers reducing to give these services.

- JLCPCB, the pioneer of another acronym, invests a huge amount and creatively accepts no replacement models of individual feeders to cure the pain of SMT sample production.

- The JLCPCB’s new effective component SMT service and global part sourcing service is their self-created and one-stop features that provide components to a global level that helps users to produce their parts in advance

- There is a high demand for components that hinders the development of the industry. JLCPCB launched the global sourcing feature to expand parts supply sources for their customers this feature will help customers to get high-quality components enabling them to achieve self-sufficiency on the JLCPCB SMT platform.

- The prices you can get from pre-order services are very favorable to the buy-as-you-go mode. Pre-order service gets a real-time quotation and charges are transparent and open.

- JLCPCB does not get any price differences and also applies a policy of many refunds and multiple supplements for pre-purchased components. JLCPCB has the ability to get less cost and quality parts from the best global parts providers.

- They have contact with many components providers with good prices. To protect their interest MOQ is a common technique used by component suppliers.

- JLCPCB’s bargaining power can help SMEs or individual customers reduce cost risks, gather various component needs and negotiate prices with trusted component suppliers.

JLCPCB Newest 1-6 Layer Double-Side Assembly

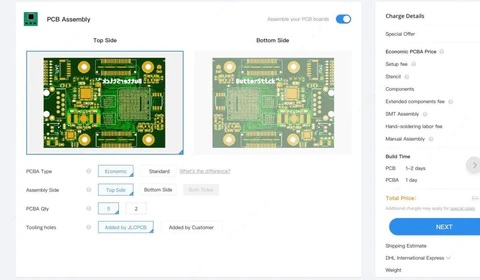

- JLCPCB’s new standard PCBA service is used for SMT batch production and double-side soldering of the board having a patch and plug-in. There is no limit for PCB board quantity also no limits for PCB process and parts types, V-Cut penalization

COST-EFFECTIVE STANDARD PCBA SERVICE

- Assembly fee: $0.0017 per joint

- Setup fee:$8 (JLCPCB $54 New User coupon free your setup fee)

- Stencil Fee: Free

- There are five boards that needed SMT every one has two hundred solder joints total of ten solder joints assembly fee with Setup fee:$8 + $0 Stencil Fee

- Standard independent online ordering mode, real-time quotation of patch order, and real-time display of patch effect, that you will see will be provided you with and short ordering process which you can master safely. In this era disturbing users is less possible in pursuit of good products

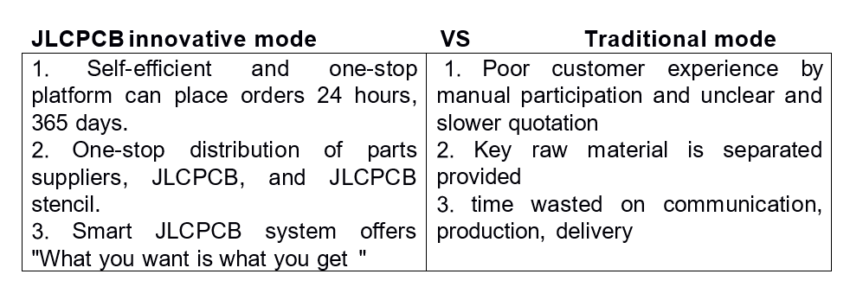

WHY IS JLCPCB STANDARD PCBA SERVICE FASTER EASIER CHEAPER?

- JLCPCB has integrated with four departments to enhance MST at full speed. The 4 PCB, components, stencil, and SMT are in a similar industrial zone.

- Then other suppliers JLCPCB transfer components, stencil, and SMT expressly save time through AGV in zone

- For ensuring the most extreme SMT experience, the JLCPCB group also has special working team members for SMT lead time and packaging in mid-March 2022. All businesses must take SMT as a priority

JLCPCB Economic PCBA

JLCPCB Standard PCBA:

Quality–assured Standard PCBA service is faster and easier

- The PCB stencil components are self-operated and they are lies in similar production areas. It is the cornerstone to make sure the quality, delivery time, and charges of JLCPCB assembly. By streamlining the complete process from ordering, parts sourcing, and PCBA prototyping and we can get products in hand just in one week or earlier.It allows you to repeat, improve and deliver on time or even faster

EASIER ORDERING FOR STANDARD PCBA

Ordering process:

- Place an order for PCB (circuit board)

- Place an SMT (SMD)order

- Payment

- Production

- QC

- Shipping

What materials do you need to prepare?\

- Components:You do not have to provide JLCPCB provides the required components

- PCB (Circuit Board): Use PCB order

- What documents do you need to prepare? GERBER+BOM+CPL

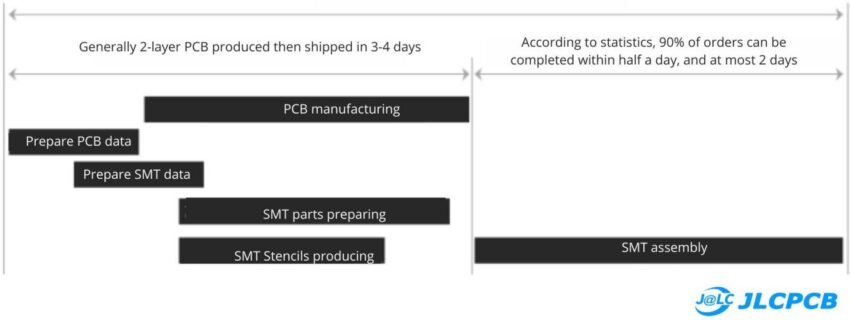

90% Of SMT Orders Only Take Half A Day Of Manufacturing

- JLCPCB has a details overview bout he effectiveness of their services so they count every single second since the faster they go more effective they become through this formula they found to provide reliable services to their users. They have started the applications of simultaneous task execution by creating PCBA supporting lines that are also getting ready instantly like components preparing, and SMT stencils. That reduces the net construction process shorter.

- The below picture illustrates the construction period of double layer board

Free $54 New User Coupon for Standard PCBA with 10M+ parts

- New User can get a free $54 Coupon

- Standard PCB Assembly supports double-side soldering, and unlimited quantity, order as many as you want

- JLCPCB SMT Parts Library 200k+ in-stock components (689 Basic components and 200k+ Extended components); and 10M+ global parts

- 10M+ parts from reliable parts suppliers worldwide

- Parts Pre-Order service from Global Reliable Parts Suppliers

- Build Personal library Inventory, Save parts for current or future orders

How JLCPCB keep Superior SMT quality by 6 self-operated industrial zones?

- JLCPCB has six self-operated factories that are equipped with high-end quality process double-sided patch and plug-in wave soldering. They are equipped with advanced Yamaha automatic palcemnt machines and all consist of the electric mast, ten temperature zone lead-free reflow soldering, automatic printing machine, mature and reliable management team, and self-developed supporting software.

- All high-precision LDI manufacturing equipment is used, and there will be no line drift and assembly welding alignment drift. The four-layer board uses LDI equipment and the two-layer board uses LDI+ automatic exposure equipment. JLCPCB only uses grade A raw material board and never uses less substance, high filler board, and non-flammable board. JLCPCB’s 4-layer PCBs are all made of Taiwan Nanya and KB genuine material grade A boards, and the price is around $72/㎡; The double-sided panels are all made of “genuine grade A” boards, about $45.74 /㎡.

https://youtu.be/pyz-kjLpZa8

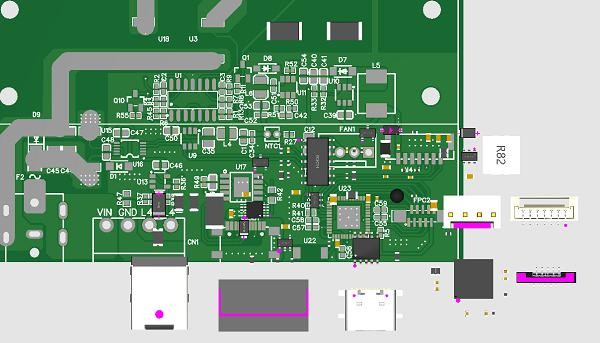

JLCPCB free DFM checking

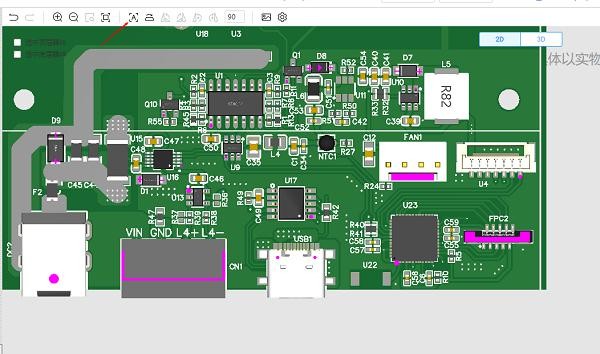

- JLCPCB Free DFM file Checking offered a 3D simulation map of physical objects. After manual pairing, you can see the effect of the repair from what you see and what you get. And one key Get $54 new user coupon. Special value-added service with SMT coupon worth $24 every month.

- After pairing, we print the log (PDF can be exported in the upper right corner). Customers can use this PDF report for their project documentation and then specify the components that JLCPCB does not have and the components that can be inserted. Purchasing staff can search for missing materials offline, speeding up the process.

- One-click alignment solves the problem of component misalignment from the pad. Due to incorrect automatic data processing or component polarity mismatch, sometimes the charged components deviate from the Taiyuan pad. At this time, manual setup is very tedious. To solve this problem, we offer a one-click fix:

- your design looks like

- Press the Auto-Align button on the toolbar to automatically align all components:

Does JLCPCB PCB Assembly make progress for Electronics Industry?

Does JLC PCB Assembly Make Progress In The Electronics Industry?

Yes JLCPCB PCA assembly helps the electronic engineer to stay healthy. The manual welding process is time taking process and uses labor with a high error are and a number of one killers of health, lung diseases, and blindness. You should quickly place an order with someone who will help you solder common components and leave your PCBA boards ready to use in industrial quality. JLCPCB Standard PCB Assembly service produces PCBA on two sides (patch + plug-in). Assembled boards can get in as little as 7 days. The standard equipment of the PCBA production line is also modified, such as an automatic solder paste printing machine, SPI (solder paste inspection), AOI, and other equipment to better ensure product quality, which helps the electronic industry and e-commerce to make progress. Get 54 new user coupons to redeem a unique double-sided PCBA path!