Hello, reader welcomes another interesting post. In this post, we will have a detailed look at PCB Assembly Procedure in PCBWay Factory. PCBWAY is china based PCB supplier that provides different types of PCBs such as single-layer multiple layers, rigid PCB, etc with reasonable price and high quality. There team members that are working in their factories are highly qualified and skilled and try to fulfill the demands of their customers.

Hello, reader welcomes another interesting post. In this post, we will have a detailed look at PCB Assembly Procedure in PCBWay Factory. PCBWAY is china based PCB supplier that provides different types of PCBs such as single-layer multiple layers, rigid PCB, etc with reasonable price and high quality. There team members that are working in their factories are highly qualified and skilled and try to fulfill the demands of their customers.

They are working on thousands of orders all over the world and delivering orders in their corresponding time. In this post, I will try to cover the details about their most famous services that is PCBA, and its construction process in their industries. So let’s get started with PCB Assembly Procedure in PCBWay Factory.

Process of SMT Soldering

- Here we will discuss all steps one by one in the detail.

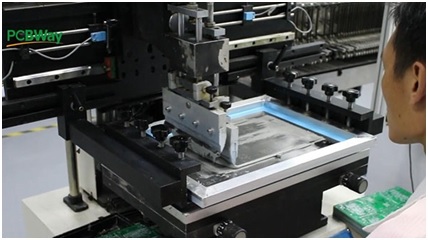

Printing Process

- For this purpose, there is the usage of soldering paste printing press is done that finds at the endpoint of the creation line to patch adhesive material at the PCB solder pad for the perpetration of elements for welding.

Adhesive Dispense Process

- In this procedure the usage of glue dispenser is done that is chiefly used for accurate spot injection of paste and other types of adhesive materials at the accurate point of every component to place at the glue for certain locations at PCB board.

Positioning of Component

- After the placing of solder paste at the PCB, the next step of placement of the component is done. Every element is obtained from the usage of a vacuum from the packaging monitored with the eyse detection system and positioned at a resultant place.

- There are numerous machines are used for this process the type of machine depends on the industries.

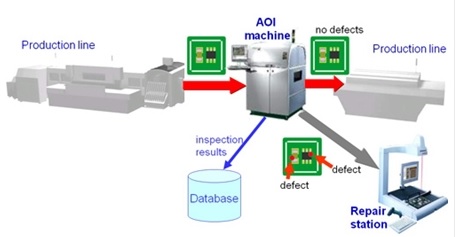

Automated Optical Inspection Before Reflow

- This is a very crucial part of the construction of PCBA is that there should be some inspection is done after placing the different component since the correct placement of component infers the complete working of the PCB board.

- For this inspection used the AOI machine to get the correct location of components.

Reflow Soldering Process

- This is a procedure that helps to connect different electric elements for temporarily at their position after that the complete packaging is offered to regulate the heat that causes the melting of solder and causes the permanent connection of joint.

- The heating process can be done by moving the complete packaging in the reflow over or infrared lamp.

- This process is mostly used for the permanent connection of component on the board it can also be used for through-hole elements after filling the holes with solder paste and adding elements points by the paste.

- Due to less cost for through holes boards wave soldering process is used.

Automated Optical Inspection after Reflow

- The last procedure for surface mounted assembly is to again detect that helps to monitor the errors caused by the AOI and checking the solder joint quality.

- In some cases, the motion during the reflow procedure causes the connection looseness or in some cases components get separated from their point.

- So inspection after reflow is very important as before it.

- The commonly used inspection methods are

- Automated X-ray inspection(AXI)

- Manual Checks

Automatic Optical Inspection(AOI)

Conformal Coating Procedure

- For the protection of component assembled on the board, there is a thing layer of polymeric material is done at the board that called conformal coating.

- The thickness of this layer is normally twenty-five to two-fifty micrometers and it also used for protecting electrical circuits from dust moisture chemicals, etc.

Final Inspection

- For this process, different types of testing tools and software are used.

Washing and Drying Process

- During the construction procedure, there is some dust and oil that exist so there is a need to remove these substances. For this washing and drying did of our product.

- After this process, the final product is reading for final packaging and delivery to the customer.

So that is a detailed post about PCB Assembly Procedure in PCBWay Factory if you have any further query ask in the comments. Thanks for reading have a nice day.