Hello readers welcome to the new post. In this post, we will discuss ceramic vs fr4.

What is Ceramic PCB?

Ceramic PCBs are a PCB board type that uses ceramic as the base material in place of Fr4 or Flame Retardant 4 epoxy resin. Ceramics is an excellent choice for different applications because of its good performance and durability benefits.

Features

- Excellent Thermal Conductivity: Good thermal conductivity may be found in ceramic materials employed on boards. In high-power applications, in particular, they effectively disperse heat produced by components, providing optimum performance and dependability. Their excellent thermal conductivity enables them for heat management and minimizes overheating problems.

- High-Temperature Tolerance: Extreme temperatures may be withstood by ceramic boards without affecting their performance. They come with exceptional thermal stability and can function dependably under challenging conditions with considerable temperature variations. This PCB board is good for applications like automotive, aerospace, and industrial industries where temperature resilience is essential.

- Low Coefficient of Thermal Expansion: The thermal expansion coefficient of ceramic materials is low. This implies that this board maintains its dimensional stability even when exposed to large temperature variations. The PCB’s durability is ensured by the low expansion coefficient, which lowers the possibility of mechanical stress, warping, or breaking.

- Excellent Electrical Insulation: Exceptional electrical insulating qualities may be found in ceramic boards. They effectively isolate conductive traces from one another, reducing electrical leakage and short circuits. Because of this quality, ceramic boards are an excellent choice for high-voltage and precise signal integrity applications including power electronics and telecommunications equipment.

- Mechanical Strength and Rigidity: Compared to other materials like FR4, ceramic materials used in boards provide good mechanical strength and stiffness. Because this board can handle high mechanical stress, they have less chance to get damaged during assembly, handling and use. Their sturdy design guarantees long-term dependability and endurance.

- Chemical Resistance: Acids, alkalis, and solvents are just a few of the many substances that ceramic boards are well resistant to. Applications that entail exposure to caustic chemicals or hostile environments can benefit from this capability. Ceramic boards can resist the corrosive impacts and continue to function properly and be structurally sound over time.

- Design Flexibility: These boards enable elaborate and complicated circuit designs by giving greater design freedom. They can support high-density interconnections and fine-pitch components. Surface mount technology, which enables the downsizing of electronic devices, is supported by these boards, enhancing overall circuit performance.

- Longevity and Reliability: These pcb boards provide long-term durability due to their sturdy design and superior heat management abilities. Compared to other PCB boards, they operate for a longer period of time, necessitating fewer replacements or repairs. Because of this, ceramic boards are an affordable option for applications needing dependability and longevity.

Advantages of Ceramic PCB

- Excellent Thermal Conductivity: Ceramics comes with a remarkable ability to transmit heat, which makes for effective heat dissipation. This characteristic is useful in high-power applications where thermal control is important, like power electronics and LED lighting.

- High-Temperature Tolerance: Extreme temperatures may be withstood by ceramic boards without affecting their performance. They are highly suited for industrial, automotive, and aerospace applications as well as hostile environments.

- Low Expansion Coefficient: Due to their low coefficient of thermal expansion, ceramic materials maintain their dimensions even when subjected to temperature changes.

- Excellent Electrical Insulation: Ceramic circuit boards are best for high-frequency and high-voltage applications because they have good electrical insulation features

- Enhanced Mechanical Strength: Compared to FR4, ceramic materials provide greater mechanical strength, which lowers the possibility of PCB board damage during handling and assembly procedures.

Applications of Ceramic PCB

- Power Electronics

- Aerospace and defense

- Automotive electronics

- LED lighting

- Medical devices

- Telecommunications

What is FR4 PCB?

The most popular type of PCB is the FR4 PCB board, which is constructed from an epoxy resin with flame-retardant properties. They are good for a variety of applications because they strike a reasonable compromise between performance, affordability, and ease of production process

Features

- Material Composition: A woven fiberglass fabric coated with a flame-retardant epoxy resin serves as the substrate for FR4 boards. This combination offers an excellent mix of mechanical toughness, fire resistance, and electrical insulation.

- Fire Retardancy: The epoxy glue used in FR4 boards has additives that greatly decrease the likelihood of a fire starting or sustaining combustion on the board. In the case of an accident, its flame-retardant quality serves to enhance the safety of electrical equipment and avoids the quick spread of fire.

- Electrical Insulation: Excellent electrical insulating qualities of this board prevent unintended electric current leakage between conductive traces. This insulation prevents short circuits and electrical leakage while preserving the integrity of the circuit.

- Mechanical Strength: FR4 PCB boards have high mechanical strength and stiffness because of the woven fiberglass reinforcing. Because of this, the boards can tolerate mechanical stress during operation, handling, and assembly. Electronic gadgets are more stable and last longer when made using this board because they are less likely to distort or bend.

Advantages of FR4 PCB

- Cost-Effectiveness: Since this board is a reasonably priced material, it is excellent for projects or applications that don’t need the unique qualities of ceramic boards but are still on a tight budget.

- Easy Manufacturing: Standard PCB manufacturing procedures may be used to create FR4boards, making them more accessible and simple to build in large quantities.

- Versatility: These PCBs may be made to fulfill a variety of performance specifications, making them finest option for use in a variety of consumer electronics, industrial equipment, and other applications.

- Good Electrical Insulation: Since FR4 board has strong electrical insulating qualities, it may be used in most electronic devices with confidence.

Applications of FR4 PCB

- Consumer electronics

- Industrial equipment

- Home appliances

- IoT devices

- Automotive electronics

- Telecommunications

PCBONLINE – High-Quality Ceramic PCB Manufacturer

The leading producer of ceramic printed circuit boards is PCBONLINE. They have gathered a wealth of experience over the years in producing and assembling ceramic PCBs. High-quality alumina PCBs, DOB LEDs aluminum nitride PCBs, , LED COBs, ceramic substrate boards for IGBTs, 3D alumina goods, etc. are all things they provide.

The LED COB module that PCBONLINE created for customers is shown below. You are welcome to request a quotation online or send an email. Your ceramic PCBs will be produced at the finest quality thanks to free design and manufacturing as well as one-on-one engineering assistance.

To create alumina PCBs, PCBONLINE employs 96% alumina. Why? Because there needs to be a balance between production costs and quality. You can see from the table below that there aren’t many changes in the characteristics of alumina with a 96% and 99% content.

The main features for FR4 by this supplier are

- FR4 PCB manufacturing skills that are strong and fulfill all of your design needs

- Extremely high-quality FR4 PCB and PCBA that are UL, RoHS, REACH, IPC, and ISO 9001:2015 certified

- For large production orders, receive a free FR4 PCB, PCBA sample, and PCBA functional testing.

- Personalized customer service and engineering support for the duration of your project

- Cheap FR4 PCBs and assemblies thanks to source factory production

- Fast manufacture and assembly of FR4 PCBs with on-time delivery

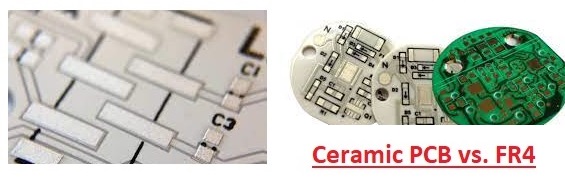

Ceramic PCB vs. FR4: A Comparison

Material Composition

Aluminum oxide and aluminum nitride are ceramic materials that are the main parts of the creation of ceramic pcbs. These materials have remarkable electrical insulation and thermal conductivity qualities. FR4 boards, on the other hand, are made of a woven fiberglass substrate and an epoxy resin that is flame-resistant.

Thermal Conductivity

Excellent heat conductivity is one of these boards’ main benefits. Ceramic materials have a strong heat-dissipation capability, guaranteeing consistent performance even in high-power applications. Contrarily, FR4 boards have less thermal conductivity, which might cause heat to build up and need the use of extra thermal management techniques.

Electrical Properties

This PCB board is ideal for high-frequency and high-voltage applications because they have good electrical insulating qualities. They provide dependable signal transmission because to their low dielectric loss and high breakdown voltage. Although they might not offer the same performance levels as ceramic boards in high-frequency applications, FR4 PCB board nevertheless offer strong electrical insulation.

4. Mechanical Strength

Compared to FR4, ceramic materials used in PCB boards provide improved mechanical strength. This indicates that ceramic boards are more durable and less likely to sustain damage during handling, assembly, or use. FR4 boards may need additional reinforcement in demanding conditions even if they are still robust since they may be more vulnerable to mechanical stress.

5. Cost

The cost must be taken into account while deciding between ceramic and FR4 boards. With their specific materials and production techniques, ceramic boards are often more costly than FR4 circuit boards. For many applications that don’t need the unique qualities of ceramic PCBs, FR4 provides an affordable answer.

Choosing Between Ceramic PCB and FR4

- Application Requirements: Consider your application’s unique needs, such as heat control, high-frequency performance, and mechanical toughness. Ceramic boards could be a preferable option if your application requires great thermal conductivity and electrical insulation. However, FR4 might be a good choice if affordability and adaptability are more crucial.

- Performance Considerations: Think about the performance compromises related to each PCB material. While FR4 offers balanced performance for typical electrical applications, ceramic boards excel in heat management and high-frequency applications.

- Budget Constraints: Analyze the project needs and your budgetary restrictions. Ceramic PCBs offer long-term stability and performance advantages while having a higher initial cost. Because they are more affordable, FR4 boards are a sensible option for applications with tight spending limits.