Hello readers welcome to the new post. In this post, we will discuss the 125 Amp Wire Size and Breaker Guide. There is a need of the correct breaker and wire size for electrical installation. These features have an effect on system efficiency and working. The use of accurate wire size and breaker for different uses like residential, and industrial are discussed here So let’s get started with a 125 Amp Wire Size and Breaker Guide

Importance of Correct Wire Size and Breaker Selection

- There are different reasons for the correct use of wire and breaker. First is that circuits function accurately and minimize the effect of overhearing, fire, and other electrical faults. The system provides accurate efficiency when operated with accurate wire and breaker that reduces losses of power

Amps and Wire Gauges Understanding

- The current passing in the circuit is measured in the ampere. The diameter and conductivity of the wire are defined in gauge measured by MWG or American Wire Gauge. Low wire gauge has a high diameter

Guidelines for Wire Size and Breaker Selection

- The accurate wire size and beaker must be used on wire current capacity, length of wire, insulation, and voltage used for devices.

- industry standards and electrical rules must also be followed

Factors Affecting Wire Size and Breaker Choice

- These parameters are the highest current load, the temperature, voltage loss, conductors insulation, and use of conductors in the same conduit,

Residential Uses

- Loads used in different circuits define how much wire size and breaker rating are needed. Outlet of living rooms needed 15 or 20 amps, kitchen appliances needed larger ampers.

Commercial and Industrial Applications

- High laos and different devices used in that applicants come with different for each device. Such types of loads are motor, lighting system, total power uses in a system defined the use of wire size and breaker

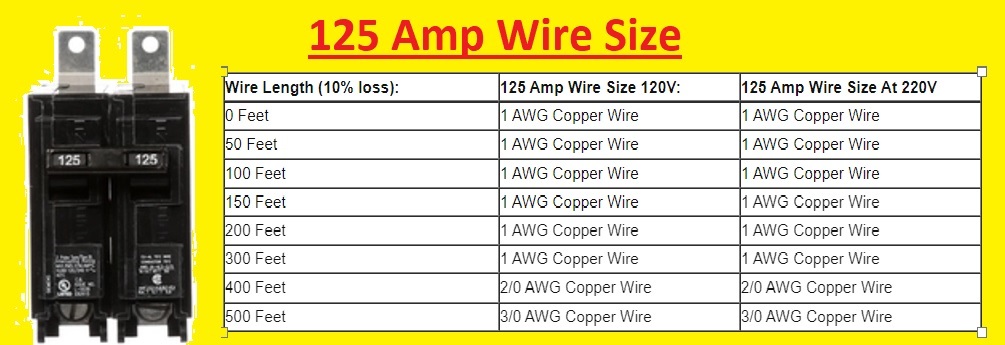

125 Amp Wire Gauge Source 0-500 Feet Away

| Wire Length (10% loss): | 125 Amp Wire Size 120V: | 125 Amp Wire Size At 220V |

| 0 Feet | 1 AWG Copper Wire | 1 AWG Copper Wire |

| 50 Feet | 1 AWG Copper Wire | 1 AWG Copper Wire |

| 100 Feet | 1 AWG Copper Wire | 1 AWG Copper Wire |

| 150 Feet | 1 AWG Copper Wire | 1 AWG Copper Wire |

| 200 Feet | 1 AWG Copper Wire | 1 AWG Copper Wire |

| 300 Feet | 1 AWG Copper Wire | 1 AWG Copper Wire |

| 400 Feet | 2/0 AWG Copper Wire | 2/0 AWG Copper Wire |

| 500 Feet | 3/0 AWG Copper Wire | 3/0 AWG Copper Wire |

What is a 125 amp service?

On the main panel, it is written at 125 amp which means your house has features to handle 125ampre easily. The electric service size helps to know the actual electrical capacity that can run at home. It also affects the number and devices connected in the circuit.

What Size Breaker Do I Need for a 125 AMP Panel?

- The breaker size for the 125 AMP panels is defined based on the panel’s highest current ability. The panel breaker size is not larger than its highest rating.

- For 120 AMP panels, there is the use of a 60 amp DOUBLE pole breaker.

- 14/3 copper feeder needs a 15A breaker. 12/3 copper requires a 20A breaker

What size of breaker do you need for a 125 amp service?

The 100 A breaker is good for 125 amp service. The breaker is not small since it will protect the current. If the wire size is small it will melt due to high current voltage and cause fire. Wire can handle curent as needed but break used to protect it.

The breaker will trip if a high current passes and saves wire. Small size breaker will trip fast but not have the ability to handle high curent.

How Many Breakers Can I Put in a 125 AMP Panel?

- Breakers are used for 125 amp panels based on the design and features of circuits. For the total panel ampere of breakers, we can add in 125 amp panels not larger than the highest ampere capacity

- Breakers come with ratings of 15, 20, 30, etc. To find breaker numbers and install first add the rating of all breakers that have to be connected.

- If there are 10 brekares of 15 amp ratings total ampre will be 10 brekars * 15 amp/breakers=150 amp.

How to Calculate Wire Size and Breaker?

- Determine the Load: first of all confirm how much load the circuit can carry easily. It is the total power use of connected devices. Ampere defines the load

- Calculate the Current: According to load measure the current required for the circuit. For this divide lad with circuit voltage.Current (A) = Power (W) / Voltage (V).

- Consider Circuit Parameters: The wire size and breaker can affected by the length of circuit insulation and temperature. Large wire dia are needed for voltage losses and heat dissipation for longer wire

- Wire Size Tables: There can be wire charts used to have accurate wire size.

- Breaker Size: Select a breaker that has a current carrying feature supported by the wire size determined. To have the correct overcurrent protection rating of breaker must be equal to or larger than wire ampacity

125 Amp Wire Gauge Source 0-500 Feet Away (3% Allowable Voltage Drop)

| Wire Gauge (AWG) | Maximum Amperage |

|---|---|

| 14 | 15 |

| 12 | 20 |

| 10 | 30 |

| 8 | 40 |

| 6 | 55 |

| 4 | 70 |

| 3 | 85 |

| 2 | 95 |

| 1 | 110 |

| 1/0 | 125 |

| 2/0 | 145 |

| 3/0 | 165 |

| 4/0 | 195 |

125 Amp Wire Gauge Source 0-500 Feet Away (10% Allowable Voltage Drop)

| Distance (feet) | Wire Gauge |

|---|---|

| 0 | 600 kcmil |

| 50 | 2 AWG |

| 100 | 1 AWG |

| 150 | 4/0 AWG |

| 200 | 2/0 AWG |

| 250 | 3/0 AWG |

| 300 | 4/0 AWG |

| 350 | 2/0 AWG |

| 400 | 3/0 AWG |

| 450 | 4/0 AWG |

| 500 | 2/0 AWG |

What is the Formula for Calculating Breaker Size?

- The formula for breaker size is

Breaker Size (A) = Wire Ampacity (A) or Wire Current Rating

What is a Normal Breaker Size?

- Normally used break sizes at residential breakers are 15 Amps, 20 Amps, and 30 Amps. These breakers are used in lighting circuits, outlets, and small appliances.

- On the need of project standards breaker size for larger devices such as conditioners, dryer, can be from 40 Amps to 60 Amps or greater.

How To Install 125A Service?

- First of all, disconnect the main pins at the meter

- At top or bottom screw knock-out clamps.

- Passes main leads in the clamps.

- Find brass bus bars and operate black and red leads to mina lugs.

- Locate the silver bus bar and pass the white lead to the main lug

- Get 10AWG ground wire in the panel. One eng passes to the ground bus. Other ned to ground rod.

- Get all the wire that needed to clamp

- Eliminate sheathing from end to circuit wires

- Eliminates half an inch of insulation from the end of a single wire

- Link white with neutral bus and bare wire to grounded bus

- Attach black wire with the terminal of the breaker

- Push breaker in the hot brass bus slot

- Operate red and black wires with the two-gang breaker.

What Is Required For A 125-Amp Service?

- Electrical infrastructure created to deliver a maximum current capacity of 125 Amperes to a crate property is called a 125-amp service. To maintain a safe and effective electrical distribution system, many standards should be satisfied to make 125-Amp service.

- Main Service Panel: Install a main service panel that can handle 125 Amperes which is adequate. Circuit breakers or fuses are used in the panel as the main distribution point for circuit protection.

- Service Entrance Conductors: Based on the electrical load, choose and install the proper service conductors. These wires connect the main service panel to the utility meter. They must be sized per the need of the electrical code and the expected current capacity.

- Grounding System: The 125-Amp service needs an accurate grounding system established. Installation of grounding conductors, grounding electrodes, and accurate metal component bonding are all added to this. By giving fault currents a path, grounding provides electrical safety.

- Circuit Breakers: To protect specific circuits from overcurrent, use circuit breakers in the main service panel. Each circuit’s electrical load demands should be followed by the breakers, which should not be larger than the 125-Amp service’s total capacity.

- Wiring and Distribution: Install electrical wiring that is the correct size and circuits for the whole structure or property. Electrical rules must be followed, the wiring should be appropriate for the intended application, and it must be able to manage the highest current demand.

- Electrical Permits and Inspections: Before starting the installation, get the electrical licenses that the local authorities will require. Schedule inspections periodically to fulfill adherence to rules and norms governing electrical work.

Wire Size for a 125-Amp Subpanel

100A Breaker Size

- The 100 Ampre breaker can be used on 125A panels. Breaker affects since it protects wires.

1AWG Wire

-

There is a need for 1AWG wire to handle 100A service. For increasing wire size there can be a 125A service used on 1AWG copper wiring

what is 125 Amp aluminum wire size?

1AWG aluminum wire is used 125 aluminum wire size

How many wires are required for a 125 amp service?

3 wires are required for the main service. Two are live wires and one is neutral wire.

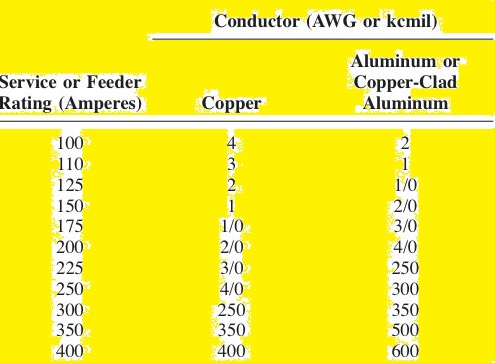

What size wire do I need for a 125 amp breaker?

| Copper Wire | Aluminum Wire | |

|---|---|---|

| 100A | 4 AWG | 2 AWG |

| 125A | 2 AWG | 1/0 AWG |

| 150A | 1/0 AWG | 2/0 AWG |

| 200A | 2/0 AWG | 4/0 AWG |

What size ground wire for 125 amps?

Six is good for both neutral and instrument grounding if not more load is needed.

What size conduit do I need for 125 amp service?

1.25″ minimum conduit would be needed

What size cable is 125 amp 3 phase?

The 125A 3-phase extension lead is connected with a 125A 5-pin IP67 Mennekes plug and coupler at both ends. The cable used is 35mm 5core H07RN-F Double insulated flexible cable designed to handle the weather, oils/greases, and mechanical and thermal stresses.

What is a 125 amp breaker used for?

What size wire do I need for 150 amps?

Can I replace a 100 amp breaker with a 125?

Conclusion:

The secure and efficient system depends on accurate wire size and breaker use. Differnt parameters such as wire sue and breaker are the main parameters for industrial and commercial projects.

FAQ

Q1. What happens if the wire size is too small for the breaker?

The result is that devices will operate forcefully with less voltage and the wire gets heated. If the wire is heated for a longer time get a fire

Q2. Can we use a larger wire size with a smaller breaker?

You are thinking of aluminum cable if needed to use 1 AWG for 100 Amps. The 1 AWG does not fit in the 40 Amp breaker or socket, thus needs to pigtail at both ends to an 8 AWG.

Q3. How do we determine the wire size and breaker for my specific application?

- Measure the total load

- Convert total load in ampers

- Choose a breaker based on amperes

- From the chart select the wire size according to the breaker

Q4. Can we rely on online wire size and breaker calculators?

Online calculators can give a rough idea, but it is not suggested to use only to get the wire size and breaker. These calculators do not consider some factors and cannot consider the electrical system’s complexity. For proper results get the services of a technician

Q5. What are the consequences of using the wrong wire size and breaker?

incorrect wire size and breaker can have many factors. Different safety risks, electrical fires, device damage, power outages, and overheating. It’s good to select the needed wire size and breaker that select the electrical load.

Read Our Latest Posts: