Hello readers welcome to the new post. In this post, we will have a look at What Size Wire Do I Need for a 60 Amp Sub Panel? The main parameter to discuss for installation of the 60 amp sub pane is choosing an accurate wire size. To have electrical safety and offer good power distribution based on the use of accurate wire gauges. Here we will learn the method for choosing the accurate wire size of 60 amp sub-panel installation. So let’s get started. What size wire for a 60 amp

Introduction to 60 Amp Sub Panel

- Subpanels are types of electrical panels that are used to make the main service panel. They provide current to different devices or areas and control the load and power distribution. Wire size is essential to make 60 amp sub panes to have proper signal integration and minimize the risk of faults.

Understanding Sub Panels

- They must have understood the panel before knowing the wire size. The sub-panel is connected to the main panel and operated as the main distribution point. it gets power from the main panel and is sent to different circuits to offer power to devices and buildings

Importance of Wire Sizing

- Accurate wire size is needed to ensure that electrical current flows through the wiring effectively and safely. Using low-sized wire can cause voltage loss, overeating, and chances of danger. The oversized wire can increase the cost and use of unnecessary resources.

Related: 125 Amp Wire Size and Breaker Guide

Factors to Consider for Wire Sizing

Ampacity

- Ampcity is the highest value of current that a wire can handle without any damage or effect from high temperature. It is good to use wire that has an ampacity rating needed or larger than loads connected with subpanels.

Voltage Loss

- Voltage losses exit when the resistance of the wire causes voltage loss. High voltage loss can result in ineffective power to reach the sub-panel, which can affect the working of connected devices. The maintenance of the required voltage needs less voltage losses.

Type of Wire

- The working and safety of penal installation can be affected by the type of wire used. Due to its high conduction and resistance to corrosion, copper wire is used. The aluminum wire can also be employed through the right connections and precautions.

Conduit Fill

- The large wire size that can be connected in the count safely is called conduit fill. When selecting the wire size for the panel they must be sure that it not go over the conduit’s capacity, following the wire size and number of conductors used

Wire Sizing for a 60 Amp Sub Panel

Calculating Ampacity

- To find the overall configuration of sub-panel demand, the amp rating of all circuits and connected devices must be added. The complete load cavity or more must support the wire size.

Determining Voltage Drop

- Then find the highest voltage loss based on installation need. Consider the different variable wire length, composition, and voltage loss in percentage.

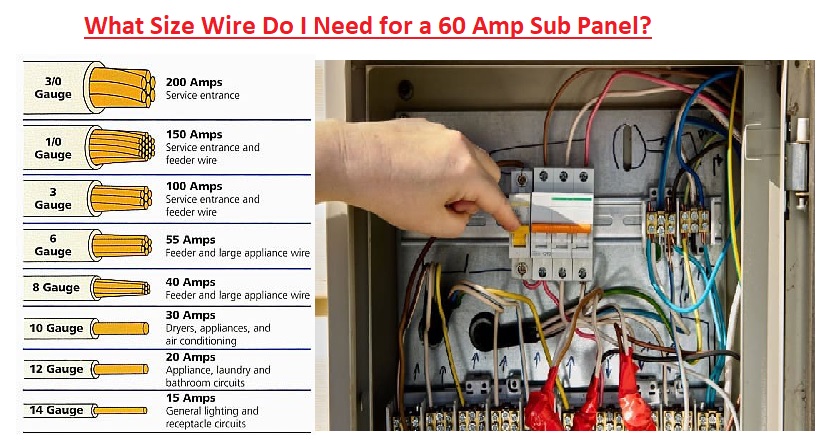

Choosing the Right Wire Gauge

- According to ampacity and voltage loss use a wire gauge chart to find the correct wire size. Ensure that the wire used is according to ampacity and voltage loss requirements.

Read also: What Size of Wire Do I Need for a 100 Amp Sub Panel?

Common Wire Sizes for 60 Amp Sub Panels

Copper Wire

- 6 AWG copper wire: it is suitable for small distances with less voltage loss

- 4 AWG copper wire: is used for projects where high voltage losses are exits or longer distances

Aluminum Wire

- 4 AWG aluminum wire: it used for high voltage losses

- #2 AWG aluminum wire: Used for projects that need high volga losses for longer duration

Installation Tips and Guidelines

National Electrical Code Requirements

- The NEC details must have compatibility with electrical safety. The NEC makes rules and specifications for wire size, grounding installation process, and other components of electrical work.

Safety Precautions

- During the handling of current safety, it must be followed. If are not sure about any installation process, use accurate protective devices, turn off the power, and get the services of an electrician.

What size wire do I need for a 60 amp sub?

- The 60 amp circuit needed a 4 AWG battery wire. This wire size make sure cable can easily handle curent without getting overheating that increases the efficiency.

60 Amp Breaker Box

- the electrical distribution panel with the highest current carrying capacity of 60 amp is known as a 60 amp breaker box. it protecs and manage eectical circuits.

- Breakers automatically trip and cut off the current if there is overloading and short circuits are the configuration of the breaker box. There is a separate circuit breaker in the box for circuitry in the building.

- If electrical demands are not larger, this circuit breaker can be connected to light commercial applications.

- it is good to know that the breaker box size can be obtained through the use of the electrical load of the building and its demand. To ensure safe and reliable electrical distribution, large capacity panels can be used if the load is later than the 60-amp breaker box.

Can I put a 50 amp breaker in a 60 amp subpanel?

Always use small rating breakers for larger rating breaker receptors. The circuit can handle a load of about fifty amperes.

60 Amp Outdoor Sub Panel

- The type of electrical panel that is made to operate for route uses and work as a secondary distribution panel is called a 60-amp outdoor sub-panel.To provide the higher circuit capacity to outdoor electrical demands it is connected to the main electrical service panel.

- The 60 amp rating indicates the subpanel’s highest current handling capacity. To reduce the overloading and other electrical damages the collective load on all circuits connected to the panel must not be larger than 60 amps.

- Outdoor subpanels are used for powering the current to lights connected to outdoors, workshops, and other outdoor devices.

- They are created to handle weather conditions and provide protection from natural hazards, snow, rain, and sunshine.

- Connecting a 60-amp outdoor subpanel needs a professional electrician to check that it is good for circuit layouts, dimensions, and conformity with electrical regulations.

What Is The Wire Size for a 60-amp Subpanel 50, 100, or 150 Feet Away?

| Amps | Wire Gauge | Distance (feet) | Compatibility |

| 60 amps | 6-gauge | 50 feet | Yes |

| 60 amps | 6-gauge | 100 feet | No |

| 60 amps | 4-gauge | 100 feet | Yes |

| 60 amps | 4-gauge | 150 feet | Yes |

What Size Cable for a 60 Amp Sub Panel?

- We must consider parameters such as cable length run and wiring type when using the right 60 amp sub-panel wire size. To ensure the effective and safe transfer of electrical current without voltage loss or overheating, the cable’s size must be proper.

- The average sire size for this subpanel is 6 AWG copper or 4 AWG aluminum. With a standard cable run length, these cable sizes are used for residential applications.

What size wire is needed for a 60 amp breaker?

Can 8 gauge wire handle 60 amps?

No 8 gauge wire is not best to use for a 60 amp breaker. For a 60 amp breaker use a 00 gauge wire having an insulation rating of 75 centigrade that can be easily used for 80 amps.

Can 8, 6, 10 gauge wire handle 60 amps?

Just 6 gauge wire has features to handle 60 amp easily and for 8 or 10 gauge wire good to have ampacity values of 40 A and 30 A.

How Much Can a 60 Amp Sub Panel Handle?

- A 60 amp sub panel is made to handle the 60 amp highest current load. To reduce overloading and electrical faults, the overall load of all the circuits connected to the subpanel is not 60 amps.

- The circuits that can be attached to a 60 amp subpanel will vary based on the demands of each circuit. To measure the total load of the subpanel, it must be noted that every circuit will come with an amperage rating.

- It’s good to consider the connected devices’ power needed when finding the subpanel’s load. Normally each device has a required amperage or wattage rating that is considered.

What Size Wire is Needed for a 100 Amp Sub Panel?

- The preferred wire size is 2 AWG copper or 1/0 AWG aluminum for a 100 amp sub-panel wire size. The capacity of these wire gauges is good to carry the connected load.

- The 100 amp sub panel wire size can be based on cable run and selected wiring technique. To ensure that accurate wire size is needed for specific installations, it is referred to use standard electrical rules.

- Additionally, it’s good to ensure that the wire is correctly installed, grounded and fulfills all electrical codes and safety standards.

What is 60 Amp Sub-Panel Wire Size?

- The wire size is 6 AWG copper or 4 AWG aluminum for a 60 amp sub panel. The capacity of these wire gauges, which are used for residential installations, is enough to handle connected loads.

what size wire for 60 amp sub-panel

60 amp sub panel wire size or 60 Amp circuit breaker are 4 AWG copper or 3 AWG aluminum. The ampacity of 4 AWG copper wire is 85 ampers for 75 centigrade and 3 AWG aluminum wire ampacity is 75 amps at 75°C.

Can you run a 60 amp sub panel off 100 amp main?

yes, we can connect a 60 amp breaker in sub panel to deliver power to the circuit if sub panel has have a rating of 100 amps and is provided by a 100 amp breaker in the main panel with an accurate size conductor providing power to sub panel.

Is 6 AWG good for 60 amps?

6 AWG wire handle 65 amperes.

Is a main breaker needed for a 60-amp sub-panel?

The 60 amp sub panel does not always need a main breaker. Certain uses and electrical codes define whether it is needed or not. If there is enough secure protection for the panel some connection helps to use the main lug sub panel then the main breaker.

What size is neutral for a 60 amp sub panel?

There is a need for 6 gauge wire for live wire and neutral wire and ground 8 gauge used. To make the connection of ground rods and connect with grounding busbar in sub panel.

Can I use a 6 3 wire for a 60 amp breaker?

6/3 is protected with the use of a 60 amp breaker. As there is no 55-ampere breaker exists so proud up to the next larger standard size used.

FAQs

1. What happens if we use the wrong 60 amp sub panel wire size?

Improper wire size can cause overheating and voltage loss. For good and safe electrical distribution, accurate wire size must be used.

2. Can we use a smaller wire size for short runs?

We can use a lower wire size for small runs. Measuring the voltage loss is needed to have in the limited range.

3. Is it better to use copper or aluminum wire for a 60 amp sub panel?

Copper wire is used since it is a good conductor and has corrosion resistance. But with accurate connections and processes, aluminum can be used.

- What size wire do I need for a 60 amp panel?

The write used for the 60 amp panel is lies on the the length of the run. For smaller runs that are less than 100 feet 6 AWG copper wire can be used. For a longer run, there is a need to use gauge wire like 4 AWG copper or 3 AWG aluminum.

- What wire do I need to run a sub-panel?

The wire needed to run the sub-panel is based on the size of the sub-panel and the size of the main breaker connected to the panel. The sub-panel breaker must be a similar size or smaller as the breaker. The wire size must be the same or more significant than the wire size that runs from the main panel to the panel.

- Does a 60 amp sub panel need a main breaker?

Yes, a 60 amp sub panel required the main breaker. The main breaker will protect all connected circuits in the panel. The main breaker must have the same or small ratings as the main breaker rating in the main panel.

- What size wire do I need for a sub-panel box?

- Sub panel comes with 2 to 12 breakers for six space panels used in indoors there is a need of 100 amp wire size and for two space outdoor panels there can be 60, 100, or 200-amp wire used

- What gauge wire for 60 amp 220v?

4 AWG copper wires or 3 AWG aluminum wires can be used For a 60 amp 220v circuit

- How many volts is a 60 amp panel?

A 60 amp panel can be either 120v or 240v. The voltage is based on the circuit connected to the panel.

- What is the best wire for subs?

The best wire for subs is copper wire. Copper wire is more conductive than aluminum wire so it can handle high currents without overheating.

- Does a sub panel need 3 or 4 wires?

A sub-panel required 4 wires:2 hot wires, a neutral wire, and a ground wire. The two hot wires can carry current to the sub-panel. The neutral wire is used to send current back to the main panel. The ground wire makes a path for the current to flow if there is a short circuit.

- Can 4 AWG handle 100 amps?

No, 4 AWG wires can only handle about 85 amps. If there is a 100 amp circuit, use 3 AWG wires.

- How much can a 60 amp panel handle?

A 60 amp panel can handle a maximum of 60 amps of current. it men’s all connected circuits in the panel cannot draw larger than 60 amps of current.

- Is a 60 amp panel enough?

it is based on the number and type of devices connected and the lights used in the home. If many devices are connected in the home, such as electric dryers, and ovens, then a 60 amp panel may not be enough.

- How many watts can a 60 amp sub panel handle?

A 60 amp sub panel can handle a maximum of 60,000 watts. it is measured by the product of amperage by the voltage (60 amps x 120 volts = 7200 watts).

- What is 60 amps in watts?

60 amps is 7200 watts. (60 amps x 120 volts = 7200 watts).

- How many volts can a 60 amp breaker handle?

A 60 amp breaker can bear 60 volts maximum, it is due to the breaker being designed to trip when the current is larger than 60 amps. If the voltage is more than 60 volts, the breaker cannot trip,

- What does 60 amps mean?

60 amps means that the circuit can handle a maximum of 60 amperes of current. Amperes are a unit of electrical current, the quality of charges that pass through the circuit in unit time.

I= Q/T

Read our latest Post: