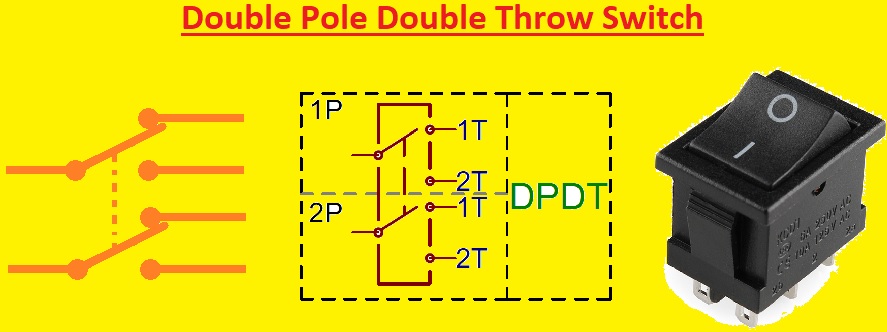

Hi, guys in this post we will cover the Double Pole Double Throw Switch. The double pole throw switch comes with 2 inputs and 4 outputs, each input has 2 resultant outputs that can connected. Every terminal of double pole switch can be in one or two states. it makes double pole double throw switch different from other switches. With the use of two inputs can connect with 4 different outputs. So let will cover its different parameters in detail in this post. So let’s get started with Double Throw Double Pole Switches

Introduction Double Throw Double Pole Switch

- The DPDT or double pole double throw is an electrical device that comes with features to control current flow in two separate circuits at the same time

- It has two poles and each pole with two through positions that make a total of six terminals. This design helps this switch two connect with two input sources and two different loads

- This switch is used in applications where many devices are controlled with one switch.

- Its 6 terminals are L1, L2, A1, A2, B1 and B2. L1 and L2 terminals are connected with incoming lines and A1, A1, B1, and B2 are connected with load points.

- Double pole double throw switch used to control two separate devices connected with a supply such as a water heater can toggled between 120 and 240 volts with the use of a DPDT switch, both supply lines or live wires must be on or off at the same time for one operates since the action is interchangeable by DPDT switch.

Structure and Working Principle of DPDT Switch

- DPDT switch comes with 6 terminals, two are independent input terminals. Every pole can complete 2 different circuits. Every input terminal is connected with two output terminals and all 4 output terminals are separated.

- It is a dual ON-ON switch that originated from SPDT features. Normally switch comes with 2 ON-ON conditioners 3 ON-OFF_ON states.

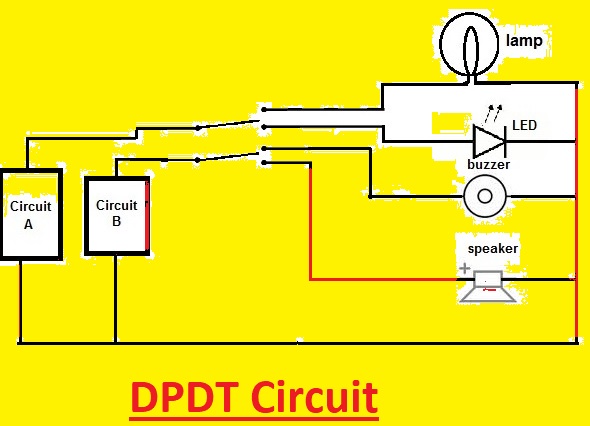

Double Pole Double Throw Switch (DPDT) Circuit

Here circuit of DPDT was made. In this diagram, circuit A is connected with a lamp and LED. If the switch is on map is on state and the LED is off.

If the switch is flipped on the other way, the LED is on and the lamp is off. Circuit B is connected by a buzzer and speaker. If the switch is on buzzer is on and the speaker is off. If the switch is flipped to the other way, the speaker is ON and the BUzzer is off.

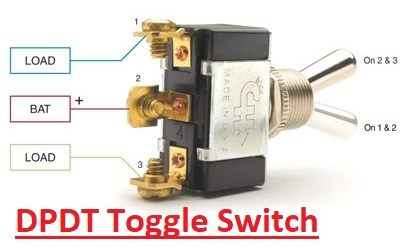

What is DPDT Toggle Switch

- Contact Configuration: DPDT

- Switch Operation: ON-ON (no center position)

- Contact Voltage AC Nom: 250V

- Contact Voltage DC Nom: 30V

- Contact Current Max: 5A

- Switch Terminals: Solder

- Actuator Style: Long Bat Lever

- Switch Mounting: Panel mount

- Bush Thread Length: 8.9mm

- Height: 0.35″

- No. of Mechanical Operations: 30000

- Operating Temperature Max: 85°C

- Operating Temperature Min: -20°C

- Contact Resistance: 30mohm

- Dielectric Strength VDC: 1000V

- External Depth: 0.45″

- External Length / Height: 8.9mm

- External Width: 0.5″

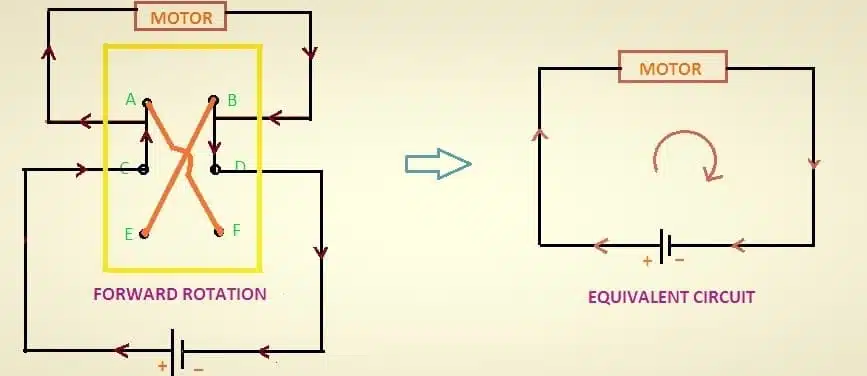

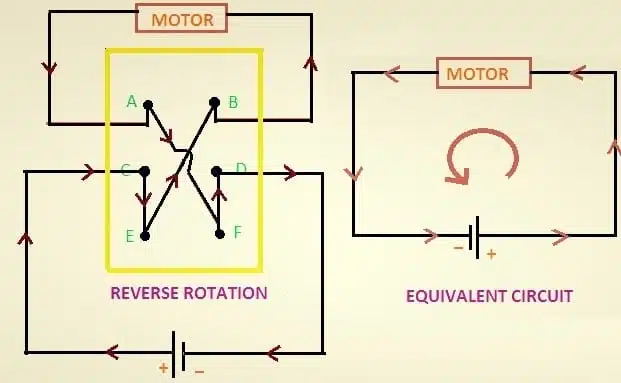

DC Motor Control using DPDT Switch

The DPDT comes with 6 terminals that are named as A, B, C, D, E, and F for easy working understanding.

- The Point A is connected with F

- The motor is connected with DPDT switches between A and B terminals. The power supply is provided to points C and D.

- Points B and E are connected, as shown in the figure.

Motor FORWARD ROTATION :

- When the switch is pushed in a forward direction point A is connected with Point C and Point B is connected with D.

- So the motor moves in a forward direction now the battery is connected in a forward connection with the motor.

- The equivalent circuit is shown in about diagram

Motor REVERSE ROTATION

- if the switch is pushed in reverse direction point C is connected with point E and point D is connected with point F.

- So the motor moves in a reverse direction as the battery is connected in the reverse direction with the motor.

Read also: What Is Double Pole Single Throw Switch

Applications of DPDT Switch

- The DPDT switch was used where open and closed wiring systems were employed.

- it is also used for the same switching of two independent signals, that operate in tandem.

- It is used to connect with a reversing switch for the electric motor.

- With the use of a DPDT switch, reverse polarity can be obtained correctly.

- it used in robots for direction control

- It is also used to choose between two separate inputs or signals for a single output. The DPDT is used to select two separate audio sources for a single amplifier or set of speakers.

- Every input terminal is connected to an output switch, that chooses the accurate source, and output terminals are connected to amplifiers or speakers.

Difference between SPDT and DPDT

SPDT

- It stands for single pole double through

- It has one pol and two throws.

- It can control one circuit

- It is used in on and off switches, Audi source, selector

- It has three terminals

DPDT

- Its full form is a double pole double throw

- It has two poles and two throws

- It can control two circuit

- it used for Motor direction reversal and two-circuit control

Advantages of DPDT Switch

- It has less weight than other switches.

- it is low cost. It has features to handle two independent signals

- it operated with high voltage and current.

- It used in different applications

- It helps to control devices at the same time.

- High switches curent helps to drive motors and control relays.

Disadvantages

- They are high cost then bridges, and it can casues network connection problems

Related: What is Double Pole Switch & its Working

Types of electrical switches

- Single Pole Single Throw (SPST)

- Single Pole Double Throw (SPDT)

- Double Pole Single Throw (DPST)

- Double Pole Double Throw (DPDT)

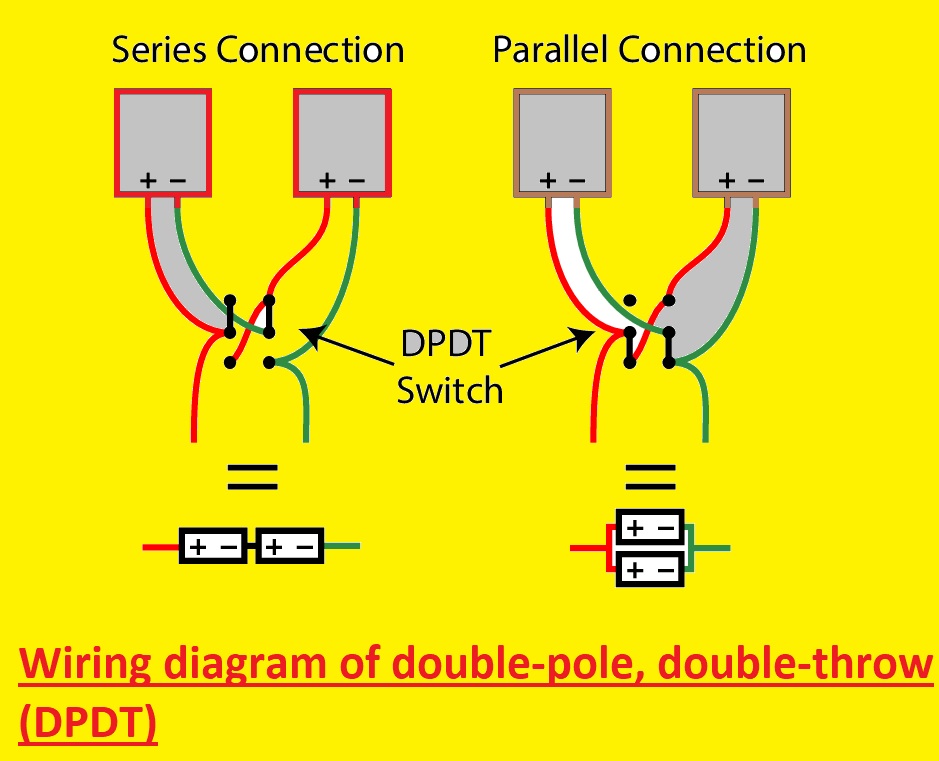

Wiring diagram of double-pole, double-throw (DPDT)

Follow these tips for the installation of the DPDT switch

- The wiring for the double pole double throw switch that chooses between series connection and parallel connection for pairs of rectenna tiles.

- The switch denotes its 6 pins with an electrical connection between pins shown for both toggle states.

Mechanics of the DPDT Switch

DPDT switch is equal to 2 SPDT switches tha operate in tandem. DPDT switch is the configuration of two SPDT circuits that are connected internally to the switch structure and these 2 circuits are operated in tandem through the common lever principle in the switch structure.

it has 6 terminals on the DPDT mechanical switch. Two C, Two NO, and Two NO

What is a double pole double throw relay?

The double pole double throw relay has two poles, each with two instantly controlled throws. The RF transfer switch or DPDT has 4 ports and two states reset or set. In the reset state, port 1 is connected to port 2, and port 3 is connected to the port.

What is the purpose of a double-throw switch?

How does a double pole double throw breaker work?

Why double pole MCB is used?

FAQs

Q: Can we use a DPDT switch to control DC circuits?

yes, it can used for this purpose first there is a need to connect the motor to the switch. Normally DPDT comes with 6 terminals and DC motor has two terminals. Terminals are denoted as A, B, C, D, E, F &G. More details are discussed above.

Q: What can a DPDT switch control?

The DPDT switch controls two separate circuits with the same actuator, which is made for the on-on or on-off-on function.

Q: Can we use a DPDT switch to control three different devices?

Double pole double throw switches control from three or more points. In other designs, low-voltage relays or electronic controls can used to switch electrical loads, without the use of extra power wires.

Q: How many circuits can a DPDT switch control?

The DPDT has 6 terminals, two are independent input terminals. Every pole can complete 2 different circuits. Every input terminal connects two output terminals, and 4 output terminals are separate.

Q: Can we replace a DPDT switch with a different type of switch?

DPDT is a double pole, double throw, equivalent to 2 SPDT switches controlled with two circuits. 2PDT is 3 poles double throw equivalent to 3 SP and DT switches controlled with 2 circuits.

Can a DPDT switch be used as a SPDT switch?

The DPDT switch is equivalent to 2 SPDT switches that operates in tandem.

What is the difference between single throw and double throw switches?

Single-throw safety switches are used when the load is fed with only one source. Doble throw safety switches are used when load is fed with any of 2 sources, but not at same time.

Is a 4 way switch a DPDT?

The 4 way switch is a double pole double throw switch, internally wired to reverse connections between input and output and have 4 outer terminals.

Read our latest Electronic Guides: