Hello, readers welcome to the new post.In this post we will discuss Construction of Flexible PCB. The PCB represents the printed circuit board, which has now become very common for us in various engineering projects and in our applications such as mobile phones, laptops, personal computers. With the introduction of PCB, our circuit assembly has become much easier and more economical. There are many types of PCB such as single-sided pcb, double-sided PCB, solid PCB, etc. in today’s post, we’ll look at a flexible PCB.

Hello, readers welcome to the new post.In this post we will discuss Construction of Flexible PCB. The PCB represents the printed circuit board, which has now become very common for us in various engineering projects and in our applications such as mobile phones, laptops, personal computers. With the introduction of PCB, our circuit assembly has become much easier and more economical. There are many types of PCB such as single-sided pcb, double-sided PCB, solid PCB, etc. in today’s post, we’ll look at a flexible PCB.

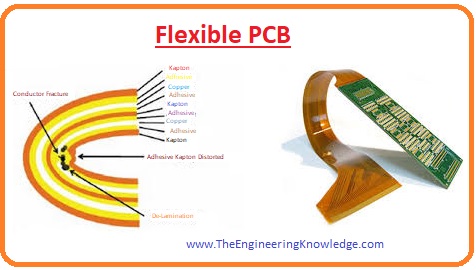

This PCB is also known as the Flex printed circuit board, its name is due to its flexible behavior. It can easily collapse and reshape. In this post we will discuss its design, functionality, applications, and other related parameters. PCBWay offers high-quality flexible PCBs at an affordable price. Depending on the circumstances, they offer all the advantages of rigid PCBs.

What is Flexible PCB Board

- A flexible printed circuit board (FPCB) is a type of printed circuit board (PCB). It allows for a variety of applications such as flexible and rigid materials. Flexible pcb is used in electronics and computer systems.

- The flexible pcb, which is made out of plastic, can be cut into many different shapes where it can accommodate whatever is needed. It can also be configured in different ways depending on the parts that are to be used and the processes that will be carried out on it. The flexibility of an FPCB allows designers to make it look like any other PCB by changing the cuts according to the needs of the project.

- A flexible printed circuit board has several advantages over a solid sheet pcboard:

- It can be made more robust – because only areas with stress are stressed and other areas remain unchanged and unaffected.

- This means that components won’t get damaged or bent when subjected to vibrations, shock or impact from multiple sources;because only areas with stress are stressed and other areas remain unchanged and unaffected.

- This means that components won’t get damaged or bent when subjected to vibrations, shock or impact from multiple sources; The passive component area has no back surface – as opposed to a metal plate that has a back surface, this means that the components will not have any metal exposed to them making them less likely to damage due to oxidation; as opposed to a metal plate that has a back surface, this means that the components will not have any metal exposed to them making them less likely to damage due to oxidation;

- The component area can be easily bent – since only small bends are required on the parts it fits in, designing an FPCB is easier than designing a single component panel; since only small bends are required on the parts it fits in, designing an FPCB is easier than designing a single component panel;

- Flexibility – since they can be cut into various shapes they have more possibilities in terms of what they are used for than solid PCBs do which limits their use cases . Although these advantages make flexibles much more advantageous than PCBs generally both types have their pros and cons so choose your preferred model based on your needs.

.

Flexible PCB Types

-

Flexible printed circuit board is an economical and versatile solution for the fabrication of small electronic projects that can be easily bent, folded, unfolded and packed.

-

A flexible printed circuit board (FPCB) is a flexible printed circuit board that can be easily bent and folded into different shapes.

-

This type of board is very useful for small electronic projects, especially those requiring a high degree of flexibility, such as robotics and robotics kits.

-

Flexible FPCBs are often used in place of rigid FPCBs because they are more cost-effective than rigid FPCBs .

-

The term ‘flexible’ refers to the ability to be bent, folded, unfolded or packed at will.

-

Although it may appear like the board can be in any shape or form when in fact it is only capable of being bent or folded in certain directions according to the requirements for a particular application

- PCBWAY has the ability to construct the different types of flexible PCB according to requirements and needs that are discussed here

Single-Sided Flexible PCB

- It comprises of a single layer of conductive material. That layer lies on the flexible dielectric material. On this board, there is one side is used for the assembly of components.

Double-sided flexible PCB

- It has two layers of conductive materials on both sides don the dielectric material. So components can be placed on both side of board.

Multi-layer flexible PCB

- It has three or more three conductive layers and each layer has its own dielectric material. The thickness of lamination is less at the bending area.

- The non-regular lamination gives large flexibility to the board

Advantage of Flex PCB

- Flexible pcb is an appropriate establishment for various engineering projects although it costs more than a solid printed circuit board.

These are some advantages of a printed circuit board.

Saving Space:

- The flexible printed circuit board design requires only 10% of the space and weight of a standard circuit board assembly, which provides high efficiency and ease of packaging. Intrinsic intensity also provides reduced bending skills.

High Reliability:

- Flexible PCBs require less flexibility, which in turn requires less cohesion, connectors, and soda points. Simply put, a flexible PCB board does not include many potential sources of disaster, which improves its reliability.

Less price:

- Less price of this circuit board provides some benefits like abridged material and wrapping demands, lesser parts replacement prices and assemblage faults that could consequence in the need for maintenance

PCBWay flexible PCB manufacturing capabilities

- The features offered by the PCBWAY for flexible PCB are listed here

| Feature | Capability |

| Number of Layers | 1-8 layer |

| Build Time | 3-5days |

| Polyimide base material | Polyimide Flex |

| FPC Thickness | 0.08-0.4mm |

| Min Track/Spacing | >=0.06mm |

| Min Hole Size(diameter) | >=0.35mm |

| Coverlay(Flex Part) | Yellow Coverlay, White Coverlay, Black Coverlay |

| Silkscreen Color | White, Black |

| Surface Finish | Immersion gold,OSP,Immersion silver,Immersion Tin |

| Finished Copper | 0.5-2oz |

Conclusion

That is all about the Construction of Flexible PCB. I have explained all aspects related to flexible PCB if you have any further query ask in the comments. Thanks for reading have a good day