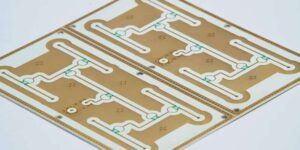

AlN PCB, or aluminum nitride ceramic PCB, is a specific board type that makes use of aluminum nitride as its substrate material. The high thermal conductivity, electrical insulation, and mechanical strength of aluminum nitride make it a special substance. By using these qualities, these boards outperform conventional PCB materials in terms of heat dissipation, electrical performance, and dependability.

Aluminum Nitride Ceramic PCB vs Other ceramic materials

- High thermal conductivity: AlN has a thermal conductivity value is 230 W/mK, which is larger than other ceramic materials, like aluminum oxide and boron nitride. This makes these ceramics best for applications where heat dissipation is important, for example in high-power electronics and RF applications.

- High dielectric strength: AlN comes with a dielectric strength of about 100 MV/m, which is also high than other ceramic materials. So it is used in applications where high voltage is used like in power supplies and inverters.

- Low thermal expansion coefficient: A thermal expansion coefficient for AIN is 4.0-6.0 ppm/°C, which is less than other ceramic materials. So AIN boards are preferred for applications where dimensional stability is needed, like in high-precision instruments and sensors.

| Ceramic Material | Thermal Conductivity | Electrical Insulation | Dielectric Constant | Cost |

|---|---|---|---|---|

| Aluminum Nitride (AlN) | High | Excellent | Low | High |

| Alumina (Al2O3) | Moderate | Excellent | High | Moderate |

| Silicon Carbide (SiC) | High | Good | Moderate | High |

| Beryllium Oxide (BeO) | Very High | Good | Low | Very High |

Features of Aluminum Nitride Ceramic PCB

- High Thermal Conductivity: PCBs made of aluminum nitride ceramic comes with heat conductivity, generally between 100 and 200 W/mK. This characteristic makes it possible to dissipate heat effectively, avoiding the formation of thermal hotspots and maintaining the dependability of electronic components.

- Excellent Electrical Insulation: This PCB provides superior electrical insulation due to its high dielectric strength and low dielectric loss. This function is essential for protecting the integrity of the signal, decreasing electrical losses, and lowering the possibility of short circuits or electrical failure.

- Mechanical Strength and Stability: Because of their exceptional mechanical stability and strength, this board can survive abrasive working conditions, vibrations, and mechanical stress. This qualifies them for uses like automobile electronics and aerospace systems, which demand dependability and longevity.

- Chemical Resistance: PCBs created with aluminum nitride ceramic are resistant to corrosion from a variety of chemicals and solvents because they have strong chemical resistance. Their lifespan and appropriateness for applications involving exposure to severe conditions are improved by this feature.

- Compatibility with High Frequencies: High-frequency applications are ideally suited for these PCBs because of their low dielectric constant and low loss tangent. They are perfect for radar systems, telecommunications, and wireless communication equipment because they allow for the effective transfer of signals without suffering significantly from signal deterioration.

- Dimensional Stability: PCBs created with aluminum nitride ceramic are dimensionally stable even when exposed to large temperature swings. As well as enabling precision construction and integration into electrical equipment, this guarantees constant performance.

- Design Flexibility: Design flexibility is provided by these PCBs, enabling intricate circuit designs, downsizing, and the integration of numerous components. Their adaptability to various production techniques, including thick film printing and laser machining, enables the development of specialized and complex PCB designs.

Applications of Aluminum Nitride Ceramic PCB

- Power Electronics: Power electronics products including inverters, power supply, and electric car parts frequently consist of this board. They can effectively dissipate heat, which guarantees steady operation and increased energy efficiency.

- LED Lighting: This PCB board is the perfect option for LED lighting applications because of its strong thermal conductivity and electrical insulation. They provide consistent performance and efficient heat management in high-power LED modules.

- RF and Microwave Devices: This board is highly suited for RF and microwave devices, like satellite communication systems, telecommunications equipment, and radar applications because of their low dielectric loss and good electrical insulation qualities.

- Aerospace and Defense: Because they can tolerate high temperatures, abrasive conditions, and high-frequency signals, these PCBs are widely used in the aerospace and military sectors.

Manufacturing Process of Aluminum Nitride Ceramic PCB

- Substrate Preparation: The preparation of the aluminum nitride substrate is the first phase in the procedure. To obtain the desired thickness and dimensions, the substrate is often manufactured using methods like tape casting, hot pressing, or chemical vapor deposition (CVD).

- Circuit Design and Layout: Computer-aided design software is used to generate the circuit design and layout. In this stage, the components are placed, the traces are configured, and the circuit architecture is optimized for signal integrity and thermal control.

- Copper Deposition: The aluminum nitride substrate is coated with a thin layer of copper using different methods like electroless deposition, sputtering, or electrodeposition. Electrical signals are routed using the copper layer as a conductor.

- Etching and Plating: The ideal circuit layout is left behind when the extra copper is etched away. To improve the conductivity and dependability of the circuit traces, further plating may be done.

- Component Assembly: The surface mount technique or through-hole technology is employed to install the electronic components, such as resistors, capacitors, integrated circuits, and connections, onto the aluminum nitride ceramic boards

- Soldering and Reflow: The necessary areas are coated with solder paste, and then the components are attached to the board. Reflow is a regulated heating procedure that is used to melt the solder and guarantee appropriate electrical connections.

- Testing and Inspection: To ensure its functionality, dependability, and electrical performance, the final aluminum nitride ceramic board is put through a series of rigorous tests and inspections. This comprises testing for signal integrity, insulation resistance, thermal conductivity, and continuity.

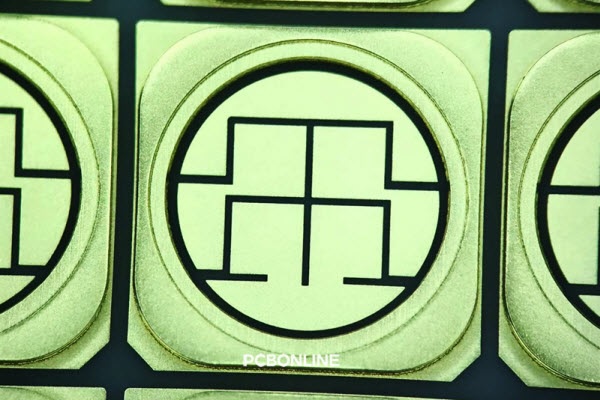

Competitiveness of PCBONLINE in Aluminum Nitride PCB Manufacturing

For the production of PCBs made of aluminum nitride, PCBONLINE uses DPC technology. By using magnetron sputtering to join a copper and aluminum nitride substrate, a ceramic circuit board with good metal crystallization qualities and flatness is created. The bonding strength between the chip and the substrate is effectively strengthened by the circuit board’s solid and dependable features.

PCBONLINE has the following technological advantages in the production of aluminum PCBs in addition to its excellent quality and three-dimensional circuit capability:

- The minimum line/spacing (L/S) at PCBONLINE is 20 m, allowing for the realization of the goods’ tiny volume, light weight, and thinness.

- AlN PCBs from PCBONLINE are more high-temperature resistant and have higher welding performance. The conductive layer’s thickness may be freely modified to be between 1 m and 1 mm.

- The copper layer of the AlN PCB does not have an oxide layer and has a lengthy shelf life in hostile settings.

- A metal layer with greater adhesion and lower resistance is present on AlN PCBs.

Projects using ceramic PCBs can receive free one-on-one engineering help (DFX) from PCBONLINE. Additionally, all manufacturing levels are accepted, and goods are made to the same high standards. Additionally, PCBONLINE assembles PCBs in accordance with IPC-A-610 Class 3 requirements.

Get $100 in vouchers for online shopping when you register online. To request a price or to speak with PCBONLINE right now, click the button or send an email to [email protected].

Thermal Conductivity of Aluminum Nitride Ceramic PCB

High heat conductivity is one of the most important benefits of these PCBs. This feature makes it possible to dissipate heat effectively, which is essential for electrical equipment that produces a lot of heat while operating. Compared to conventional board materials such as FR-4, aluminum nitride ceramic boards have thermal conductivities that generally vary from 100 to 200 W/mK.

Aluminum nitride ceramic boards assist in maintaining lower operating temperatures, minimizing thermal stress on components, and prolonging their lifespan by effectively dispersing heat. This is especially useful for high-power gadgets or applications where heat control is important, like LED lighting, power electronics, and automotive systems.

The danger of hotspots and temperature-induced failures is decreased because of the aluminum nitride ceramic board’s excellent thermal conductivity, which makes sure that heat is swiftly transferred away from heat-generating components. So the performance, dependability, and lifespan of the system as a whole are increased.

Design Considerations for Aluminum Nitride Ceramic PCB

- Thermal Management: Utilize the aluminum nitride ceramic boards’ excellent thermal conductivity by strategically placing heat-generating parts and adding the right heat sinks or thermal vias. This guarantees effective heat transfer and averts temperature-related problems.

- Circuit Layout: Analyze the circuit layout thoroughly to reduce trace lengths and maximize signal integrity. To ensure signal integrity, take into account the high-frequency properties of this board and employ methods such as controlled impedance routing.

- Component Selection: Select parts that work with aluminum nitride ceramic boards” operating temperature range. Make sure the components you choose have the ability to bear mechanical stress and vibrations associated with the application and have the appropriate thermal properties.

- Environmental Factors: Take into account the surroundings in which these boards will function. Consider how changes in humidity, temperature, and any exposure to chemicals or solvents may impact the PCB’s performance and durability.

- Manufacturability: To guarantee design viability and manufacturability, work closely with producers skilled in aluminum nitride ceramic board manufacturing. Think about the particular production techniques that are appropriate for use with aluminum nitride ceramic PCBs, such as laser machining or thick film printing.