Hello readers welcome to the new post. In this post, we will have a look at the 50 amp sub panel. During the installation of a 50 amp sub panel, the choice of correct wire size is needed to ensure safe and reliable power distribution.n this post, we will cover the different factors for accurate wire gauge for 50 amp sub panel installation with different wire sizes and their installation. So let’s get started with 50 Amp Wire

Introduction to 50 Amp Sub Panel

- Subpanels are electrical panels used to provide power to different devices and locations homes and offices for different devices connected

- They are used in garages, workshops, and other circuits.

- To install the 50 amp sub panel use the correct wire size to handle electrical loads and safety measures

Importance of Wire Size in Sub Panels

- The wire size is needed for the configuration of the sub-panel since it provides the highest current capacity and avoids voltage loss problems.

- If the wire used is not good can cause overheating issues and also increase the resistance and fire hazards. it is a waste of resources if not use the proper size wire that is not accurately connected to the panels

Determining the Load Requirements

- Before the selection of wire, the need for electrical loads of the panel

- Check the device and component connected with the panel and their ratings, Add all loads to get the total current need. For the 50 amp sub panel, the highest current value is known

Voltage Drop Considerations

- Voltage loss occurs when current passes through the wire and reduces voltage according to length. High voltage loss can cause faulty operating devices and an error in the power supply. To ensure effective pannal installation voltage losses must be controlled

Choosing the Right Wire Gauge for a 50 Amp Sub Panel

National Electrical Code (NEC) Guidelines

The National Electrical Code has different guidelines for the selection of wire sizes for different applications. Based on 50 amp sub panel needed, the least wire size is 6 AWG for copper material conductors and 4 AWG for conductors created with aluminum.

Copper vs. Aluminum Wiring

- For sub-panel wiring, 2 conductors aluminum and copper were used. Copper wiring is mainly used due to high conductivity and is mostly preferred for residential uses

- Aluminum wiring is less costly but comes with high resistance. So it be used according to NEC details

Factors to Consider

Follows these parameters for wire gauge for a 50 amp sub-panel installation.

Distance

The length of wire between the sub-panel and the main panel is good for the use of an accurate wire gauge. Longer wire increases the resistance and voltage loss increases. It is necessary to measure distance correctly to find the accurate wire size

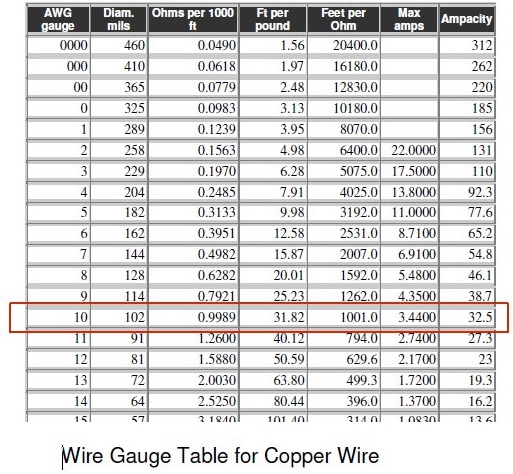

Ampacity

The current carrying feature of wire is called ampacity. For 50 amp panels wire used has an ampacity value equal to or larger than the curent capacity. it is good to follow the details of NEC to make sure the wire can easily handle loads

Conduit Size

The size of the conduit used for running wires among the sub-panel and main panel also affects wire gauge selection. The conduit must have good space to handle wire size easily. it is good to follow electrical codes for conduit sizing to ensure accurate installation

Common Wire Sizes for a 50 Amp Sub Panel

Copper Wire Sizes

For a 50 amp sub panel, copper wire sizes are

- 6 AWG: it is less recommended wire size according to NEC instructions for copper conductors in the installation of these panels. it can handle the required current capacity accurately and is best for residential uses

- 4 AWG: It is not commonly used for 50amp panels .4 AWG wire can be used for larger distances and there are fewer voltage losses. It offers safety measures

Aluminum Wire Sizes

- 4 AWG: According to NEC aluminum wire is the least recommended size for these panels. It has a larger dia than copper wire but can handle the required current capacity

- 2 AWG: For longer distances use of 2AWG aluminum wire helps to minimize voltage loss and ensure effective power distribution. It is best to follow electrical codes and regulations since some require larger wire sizes for aluminum

Explore Our Coins Articles:

How to install Sub Panel Wiring

Safety Precautions

- Must turn off the power supply before start working

- Wear gloves and safety glasses

- Follows the local electrical codes to ensure compliance

Proper Wire Termination

- Remove the wire insulation for proper length to ensure the secure connection of panels

- For accurate termination use wire connectors or terminal blocks

- Tight all connections to minimize the risk of losses of connection and electrical hazards

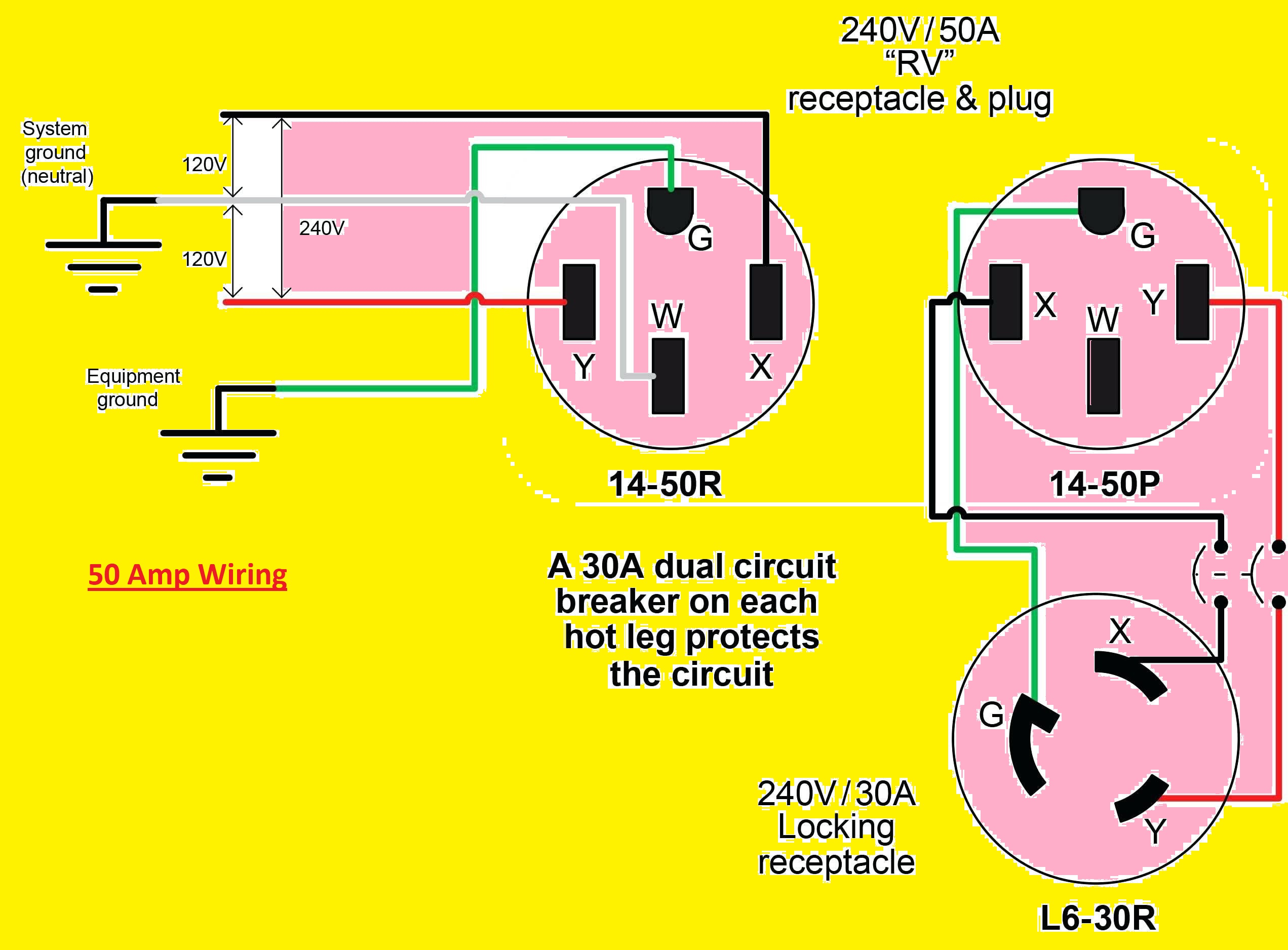

What is 50 Amp Wiring

50 amp wiring is made for handling certain electrical loads. It has two conductors, hot wire and neutral wires that carry current in opposite directions. For 240-volt circuits, a 50 amp wire can also have 2nd hot wire that helps split-phase system.

Applications of 50 Amp Wire

- RVs: Recreational vehicles use 50 amp wires to provide power to differnt components and systems at the same time. It ensures the correct power supply for air conditions, kitchen heating

- Hot Tubs: Hot tubs and spas require power for heating components controls and pumps. this type of writing offers needs electrical current with safe and easily

- Electric Vehicle Charging Stations: Electric vehicles are now commonly used and required charging stations are increasing. It does fast charging and helps with high power needed to fulfill electrical vehicles

- Industrial devices: Certain machines and devices like compressors, motors, and welders need this wiring to handle their power demands

Read also: CR2025 vs CR2032 Batteries

Correct Wire Sizes for a 50A Sub Panel

The correct wire sizes for a 50A sub-panel are:

- Copper: 6 AWG

- Aluminum: 4 AWG

The wire sizes are based on NEC. NEC needed the wire size to be large enough to carry the current load without overheating. The NEC needs the wire size to be large enough to handle the current load without overheating. In some cases, there is a need to use a larger size of wire if the panel is attached to a longer distance from the main panel. It is due to that voltage losses about the wire will be high and a larger size is required to sustain voltage at sub-panel

What is 50 Amp Sub Panel Wire Size

The wire size for a 50 amp sub panel is based on maximum current capacity, main panel, and wire material. 50 amp wire size needs the least wire size is 6 AWG and 4 AWG for aluminum conductor.

Wire for 50 amp service

50 amp service, selecting the accurate wire size is effective and important. The correct wire size is selected according to the distance between the load and power supply highest current capacity and the wire material.

Mostly a 50 amp service has wire size 6 AWG for copper conductors and 4AWG in case of aluminum conductors.

What Size Wire for 50 Amp Breaker

To maintain a safe and effective electrical distribution, Different parameters must be considered for the right wire size for a 50 amp breaker. The length of the wire, maximum current capacity, and the wire material all influence its size.

As a general rule, it instructed to use wire sizes of 6 AWG for copper conductors and 4 AWG for aluminum conductors when using a 50 amp breaker.

What Size Wire is For a 50-Amp Subpanel?

The distance between the panel and subpanel voltage, and load connected on the subpanel helps to find the value of accurate wire size for a 50 amp subpanel. The gauge of wire means wire size, high gauge means the wire is thick and handles high currents. The normal wire for 50 amp subpanel on 250 volt circuitry is 6 AWG copper and 4AWG aluminum.

8-Gauge Wire For 50 Amp

No, the 8-gauge wire cannot safely carry 50 amps. The ampacity of the eight gauge wire is 40 A at sixty degrees Celsius, which is the standard temperature for electrical parameters. If there is an 8 gauge wire for a 50 amp circuit wire will get heated very much and can start a fire. The least wire size for a 50 amp circuit is 5 gauge. The 6 gauge wires have an ampacity value of 60 degrees Celsius, which is larger than the handle of the current safety.

If there is a needed 100 feet wires then use a larger wire size to avoid voltage loss. Voltage loss can cause devices and other electrical component to not work correctly

the ampacity of different wire sizes for a 50 amp circuit:

| Wire Size | Ampacity |

|---|---|

| 4 AWG | 85 A |

| 6 AWG | 55 A |

| 8 AWG | 40 A |

wire size for 50 amps 240 volts

The wire size for 50 amp 240 volts is 6 gauge copper or 4 gauge aluminum.

wire size for 50 amp sub panel 100 feet away

If the sub-panel lies at 100 feet distance, use 4 gauge copper or 3 gauge aluminum wire. Ensure that the wire can carry curent without overheating and getting damaged

what size wire for 50 amp 200 feet

For wire of 200 feet use a 3 gauge copper or 2 gauge aluminum wire.

what size aluminum wire for 50 amp sub panel

The wire size for a 50 amp sub panel with aluminum wire is 4 gauge.

how far will 6 gauge wire carry 50 amps?

A 6 gauge wire can carry 50 amps for 100 feet. If the wire is longer than 100 feet, use a larger wire size

gauge wire for 50 amp 220v

The wire size for 50 amps 220v is the same as the wire size for 50 amps 120v is 4 gauge copper or 3 gauge aluminum wir Voltate does not affect wire size

what size wire for 50 amps at 75 feet

If the wire is 75 feet long, use a 4 gauge copper or 3 gauge aluminum wire.

Is an 8-gauge wire good for carrying a 50-amp electrical load?

The 50 amp load does not carry an 8 gauge wire. The larger wire gauge like 6 AWG of copper and 4 AWG aluminum is used for a 50 amp circuit. Using 8 gauge wire can casues overheating and harmful results. For an accurate wire size of the required load follow NEC code.

How to measure the distance between the main panel and the subpanel for wire size selection?

determine the length of the wire to get the distance for wire size between the main panel and the subpanel. The thick wire gauge is required for compensation of high resistance and voltage losses that is due to longer distances. For choosing the accurate wire size of the 50 amp sub panel follow voltage loss limitation according to distance, which can get in the NEC code.

What size wire do I need for 50 amp 240 volt?

For highest of 50 amperes, there is a need of a 6 gauge wire. 50 amo breaker is used to power different devices. The kitchen oven needed 50 amps.

Will 8 gauge wire carry 50 amps?

The 8 gauge copper handles 50 amps but it will get heated.

What size wire do I need for 40 amp 240 volt?

8-gauge wire

Conclusion

For a 50 amp sub panel to deliver curent in safe conditions and an effective way the accurate wire size is selected. Considering different parameters such as distance, ampacity, and conduit size will help in selecting the right wire gauge size for certain installations.

Following the safety measures and giving the necessary installation requirements. Fellows the safety measures and make sure installation is correctly done. We can make an effective sub-panel system with the use of proper wire size using the right installation process.. follow for more updates solar system diagram

FAQs

Q: Can we use a smaller wire size for my 50 amp sub panel?

A: it is not suggested to use a smaller size of wire than the NEC guidelines. Smaller sizes of wire get overheating, resistance, increase, and potential safety hazards.

Q: Can we use copper wire for a 50 amp sub panel instead of aluminum?

A: Due to good conduction it has been used for 50 amp sub panels since.

Q: How to determine the wire size for my specific sub-panel installation?

A: Conduit size and ampacity are parameters that define accurate wire sizes.

Q: What is voltage drop, and why is it important in sub-panel installations?

A: Voltage drop is caused when curent flows through wires. If instruments are not working accurately improper power supply can cause excessive voltage drop. Voltage loss must be in a safe condition to have effective electrical distribution.

Q: Can I install a 50 amp sub panel myself, or should I hire an electrician?

A: it is suggested to install a sub-panel by a professional technician who needs to know how to connect it accurately.

How thick of wire do I need for 50 amps?

6 AWG wire for 50 amps. it is a minimum-size wire that can easily handle the current a 50-amp circuit.

What wire is best for 220v 50 amp?

The best wire for 220v 50 amp is the THHN wire. THHN is a copper wire that is used for high-voltage applications. It has resistance to heat and corrosion, so best for 220v circuits.

Can you use 8 AWG for 50 amps?

No, use the 8 AWG wires for 50 amps. 8 AWG wire is rated for 40 amps, so it will not be safe to use for a 50 amp circuit.

How many watts can a 50 amp breaker handle?

A 50-amp breaker can handle 12,000 watts. it is measured by multiplying the amperage of the breaker with the voltage of the circuit. For, 50 amps x 240 volts = 12,000 watts.

How many watts are 50 amps at 240v?

50 amps at 240v are 12,000 watts. It measured as 50 amps X 240 volts = 12,000 watts.

How many amps is 240 volts?

240 volts is 120 volts x 2. It is due to 240 volts are 2-phase voltage, that is sum of two 120-volt phases.