Hello friends welcome to the new post. In this post, we will discuss the Overview of Flex PCB Panels: Definition, advantages, and applications. The common type of PCB baord is a rigid board but flex type is also used and different manufacturers are now making these boards. In this post, we will discuss the definition, advantages, and use of flex PCB panels, as design considerations

What are Flex PCBs

A Flex PCB (flexible printed circuit board) is a PCB type that provdies flexible structure for designs. Flex boards are made with the use of plastic of a flexible nature, bending and reshaping structure.

As compared to rigid boards that are hard structures and non-flexible, flexible boards can easily bend and part of complicated design structures can get the required shape due to their flexible nature.

Flex board reduces motion and vibration that is provided by rigid boards. its desing helps to reduce weight by 70 percent which is the main featues of the flex board. it also comes with limited connections which is a feature of Flex PCBs. It helps to avoid interconnection errors like solder joints, and defective interconnections

Types of Flex PCBs

Single-sided Flex PCBs

Common flexible boards are single-sided flex boards, and this flexible board comes with a conductive copper layer on only one side of the flexible substrate. For a thin sheet of paper, a flexible polymer is used. At time of the soldering process, some holes are made that lead of component to pass. In this process, single-sided flex boards are made. It is cost-effective and easy to make and design. it comes with relatively less complicated circuitry.

Double-sided Flex PCBs

Double-sided flex boards come with conductive layers on both sides. It comes with complicated circuit than single-sided flex boards. it comes with high density for component packing. The double-sided flex boards and copper layers are connected through PTH or vias, providing active circuits made with layers

Multilayer Flex PCBs

Multilayer flex boards that come with 3 or conductive layers are made with a combination of double and single-sided flexible designs, connected through the use of adhesive layers, and linking them using plated vias. The design of multilayer flex boards is complicated thatn double-sided flex boards. it can add many conductive layers that are parted through insulating layers. it comes with design featues and is best for complicated electronic systems with high component density.

Rigid-Flex PCBs

Rigid-flex boards called its name due to the combined features that boad offers. it comes with rigid and flexible circuits that make a hybrid circuit board. These boards are made by combining flexible and rigid materials on a single board, offering a board that mixes the advantage of rigid and flexible PCBs.

.

Applications of Flex PCB Panels:

Flexibility

- It is the main featues and benefit of flex board and flexible in shape and size that is the main benefit of flex board. This feature is applied where rigid boards are best to use

Low Weight

- Than rigid boards, flexible board comes with less weight and these features make them best for uses where low-weight components are used. it is used for aviation and defense uses. These features come with the need for portable electronic applications.

high density

- Packaging of flex board is high density so can have a larger number of components in a small and compact surface area. It helps the integration of components in small areas and also provides manufacturing of miniaturized electronic components.

3D Configuration

- These boards come in irregular geometry and due to the 3D configuration supported by their use in certain applications. Flex boards can bend and be configured in a way that makes PCBs in requried uses and this feature provdies configurations.

Fewer Interconnects

- It occurs due to the reduction of connectors and needs fewer solder joints. it helps to make reliable boards with durability.

Resistance to Vibration

- Then the rigid board’s flex boards have vibration resistance. it comes with high power for absorbing and distributing vibration smoothly. This feature is applied for vibration-resistant applications.

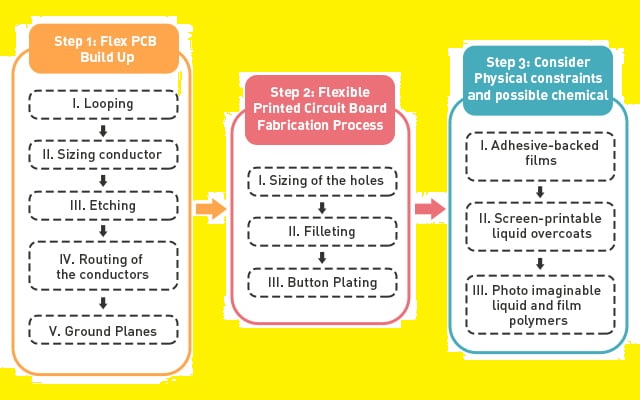

Manufacturing Process of Flex PCB Panels

Design

- First of all, design is made for that planning is made and listing for required materials. The design of the flex board is made according to the required parameters.

Preparation of Materials

- For material preparation, the photoresist film is used. it makes sure that panels are cleaned with chemicals before film application. Normally polyimide-based materials are used for the manufacturing process.FR4 and rogers 4003 are used with each other with a combination of polyimide materials for rigid-flex boards. The use of materials is based on the manufacturing process and component connection and is used for solder masking

Pattern

- It is the main phase of the PCB manufacturing process. Here panels are coated with photoresist are put over desired circuit patterns. These patterns then shifted to panels with the help of UV (Ultraviolet) light.

Etching and Drilling

- Etching is the main phase of manufacturing that comes with the removal of unrequited materials on the PCB with the use of etchant in the plating tank. Etchants can be sulfuric acid based and remove traces of copper from the board. After etching drilling of the board is made. The metallic pad exposure is made on the backside of the panel after drilling processes

Copper Plating and Coverlay Applications

- Copper plating is made with different chemicals. it is operated by filling in pads and traces on board through the use of plating chemicals. It will make the desired copper-plated circuit board.

- Coverlay is made on board after copper plating to make sure of accurate components. It saves components from affecting during the drilling and soldering process.

Stiffeners Application

- The stiffener is a thin layer of copper that is added to the flex boad after overlay applications. Stiffeners are used for supporting flex boards during processes like bending, soldering, and inserting at high speeds.

Electrical Testing

- Different tests are performed at the last step to check the proper working of the board

Design Guidelines for Flex PCB Panels

JLCPCB is a famous PCB supplier and exists in China. It has been working as one stop supplier for different PCB-based services since 2006. it offers its clients easy-to-afford boards with quality and low cost.

They offer differnt services such as flexible PCBs, also referred to as Flex PCBs.

JLCPCB offers high-quality flex PCB beginning at a special offer price of $25 for 5 pieces. . For new customers, $54 register vouchers are available.

There are a few things to keep in mind while ordering flexible PCBs from JLCPCB. Unlike inflexible PCB panels that uses mouse bites or V-cuts, FPC panels are constructed differently.

Requirements for Flex PCB Panels on JLCPCB

- 2 mm internal board spacing and 3 mm for metal stiffeners used

- 5 mm panel borders made on all sides of boards. Copper should exist on borders without one mm clearance about fiducials and 0.5 mm around tooling holes.

- SMT fiducials are 1 mm in diameter and tooling holes 2 mm in diameter. Fiducials are 3.85 mm from the center to the panel edge. One fiducial and tooling hole must applied in every corner of the panel, offsetting then in one corner through 5 mm to show the proper direction

- Connecting tabs can be about 0.7 to 1.0 mm wide.

- Panels dimensional are 234 × 490 mm and 70 × 70 mm.

- The panels that face SMT assembly use one fiducial next to each FPC unit. The board manufacturing shows defective units to not be covered with paint over its fiducial.

- ForFPCs with metallic stiffeners there can be about 3mm of space between boards and 0.8 mm of space around the stiffener for laser cutting.

For getting accurate working with flexible baord design it is good to use proper materials for board manufacturing. JLCPCB cooperates with the best raw materials provider to offer quality services and A-grade boards for different uses. With that JLCPCB comes with 5 self-intelligent production bases that are used for economies of scale, causing reduced production costs so able to give advantages to customers as much as possible JLCPCB offers new users up to $54 sign-up coupons. Click here to sign up on the website, upload your Gerber files, and get quality flexible boards