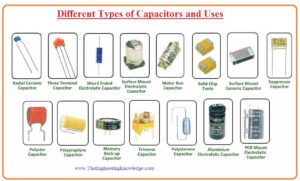

Hi, reader welcomes to a new post in this post we will have a detailed look at Different Types of Capacitors and Uses Capacitors is produced in numerous arrangements, panaches, dimensions, circumferences, and from numerous types of substances. All these capacitors consist of two plates which are separated by any dielectric material. They are used in numerous circuitries as the main component for charge storage or many other functions like power factor correction. the capacitor is also known as passive device.

Hi, reader welcomes to a new post in this post we will have a detailed look at Different Types of Capacitors and Uses Capacitors is produced in numerous arrangements, panaches, dimensions, circumferences, and from numerous types of substances. All these capacitors consist of two plates which are separated by any dielectric material. They are used in numerous circuitries as the main component for charge storage or many other functions like power factor correction. the capacitor is also known as passive device.

Minor or (small) capacitors are used in different electronic instruments to pair signals among phases of intensifiers, as electronic filters and adjusted circuitries. While larger capacitor is used for storing of power in such submissions as strobe lights, in motors for starting current provider, and it is also used in grid stations for correction of power factor. Capacitors are used according to their capacitance, operating voltage, or current conducting abilities.

What are the Types of Capacitor

- Many kinds of capacitors are obtainable in the marketplace and every one has its own features and submissions.

- The categories of capacitors obtainable range from very minor subtle trim capacitors which used in oscillation circuits or radio circuitries, and larger capacitors which are used in higher power correction circuits.

- The judgments among the dissimilar kinds of the capacitor is usually made for the insulating material used among the electrodes of capacitors.

- Similar to resistances there is also a variable capacitor that changes their capacitance in radio and frequency changing circuitries.

- Marketable categories of capacitors are created by metal foil interweaved with tinny slips of either paraffin saturated sheet or Mylar as the insulating substance.

- Some capacitors have a shape like pipes since the metallic foil sheats are converted into a tube shape to make a trivial packaging with the protecting insulating substance inserted among them.

- Small-size capacitors are mostly built with earthenware substances and then dip in an epoxy gum to cover them.

- Moreover, capacitors give a very significant contribution in electric circuitries so some important types of capacitors are described below.

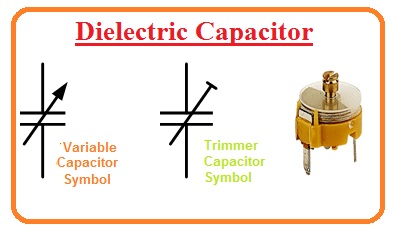

Dielectric Capacitor

- Dielectric Capacitors are generally of the adjustable category where an incessant alteration of capacitance is essential for tuning transmitters, receiving circuits and

- Adjustable dielectric capacitors are multiple plate air spread out categories that have a pair of static plates and a pair of transferable plates which do motion amid the immovable plates.

- The location of the movable plates with reverence to the immovable plates governs the complete capacitance quantity.

- The capacitance value is extreme when the two pairs of plates are completely interlocked with each other.

- High voltage sort tuning capacitors have moderately larger spaces among the plates with failure voltages accomplishing numerous thousands of volts.

Fixed Capacitors

- Numerous kinds of fixed capacitors are used in the electronic industry.

- They are intended to have a static quantity of capacitance.

- Such capacitors are categorized as rendering to polarity. The polarized and non-polarized static capacitors can be supplementarily categorized by the insulating substance used.

- Generally, fixed capacitors is called insulating substances used in them.

Ceramic Capacitor

- These are non-polar capacitors. Their capacitance values exist in picofarad to microfarad ranges.

- These capacitors have existed in numerous categories with respect to voltages. Like some volts to KV.

- These capacitors have to types first one is a disc and the other is multiple layers.

- The assembling of the disc capacitor is very modest. They consist of the little ceramic-created disc which is painted with a silver coating which is called as disc capacitor.

- Ceramic-created discs and covering of silver is work like earthenware electrical and electrodes correspondingly.

- The disc and silver conductor assemblage is covered with padding for the shield.

- These capacitors have values of capacitance from 0.5 to 1600 picoFarad.

- The insulating material can be plate-like for the platter, or tabular types of ceramic capacitors.

- The value of capacitance for these kinds of capacitors is between one picofarad to one microfarad.

- the failure voltage for this capacitor is making five hundred volts to twenty kilovolts.

- Multiple layer ceramic capacitors are also known as MLCC, these capacitors are mostly used to gain higher capacitance.

- The higher values of K upsurge capacitance © of ceramic capacitors retain their dimensions small. such kind of capacitors are well suited for higher frequencies.

- They are universal drive capacitors and are mostly used to eliminate sound in different circuits.

- As we discussed earlier this capacitor has a nonpolar nature so it can be used in both Alternating current and direct current circuitries.

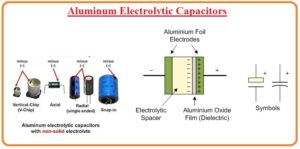

Aluminum Electrolytic Capacitors Construction

- There are two main kinds of Aluminum Electrolytic Capacitor, the first one is plain foil and the second one is imprinted foil.

- The depth of the aluminum oxide sheet and higher failure voltage provides these capacitors with very high capacitance.

- The foil sheet capacitor is anodized with a direct current. This anodizing processing makes polarizes the plate substance and shows which is a positive side and which is negative.

- While The etched foil capacitor varies from the plain foil capacitors in which the aluminum oxide at the anode and cathode outwits has been chemically imprinted to upsurge its area and permittivity.

- Due to this, it becomes smaller in size than plain foil capacitors of equal values but it has the drawback that it can bear the higher direct current as compared to plain sheet capacitors.

- Their acceptance or tolerance values are very large near to twenty percent.

- Distinctive values of capacitance for an aluminum electrolytic capacitor is from one microfarad to 47,000 microfarad.

- This capacitor is mostly used in coupling, DC blockage, and bypass circuitries, whereas plain foil works as flattening capacitors in power supplies.

- But aluminum electrolytes are “polarized” diplomacies so changing the provided voltage on the probes will cause the isolating coating in the capacitor to get demolished with the capacitor.

- But, the electrolytic used in the capacitor aids settle an injured plate if the harm is minor.

- As the electrolytic material has features to self-healing of the injured sheet, it can do the anodizing the foil sheet.

- Meanwhile, the electrolytic substance can flow current through it, if the aluminum oxide coating was detached or demolished, then-current will pass from one plate to other plates of the capacitor so always be aware

Mica Capacitor

- This type of capacitor uses mica as an insulating material coated with a thin silver coating. Due to this, these capacitors are also named as silver mica capacitors.

- These capacitors exist among the capacitance ranges of some picofarad to thousands of pico farad according to their voltage ratings.

- The insulating material in the mica capacitor is used as slanted films.

- The capacitance values of this capacitor is from ten picofarads to five thousand picofarads.

- These mica capacitors provide higher exactness, consistency, and permanency.

- They are existing in trivial capacitance ranges and are usually used at higher frequencies and in circumstances where less loss and less capacitor changing time are vital.

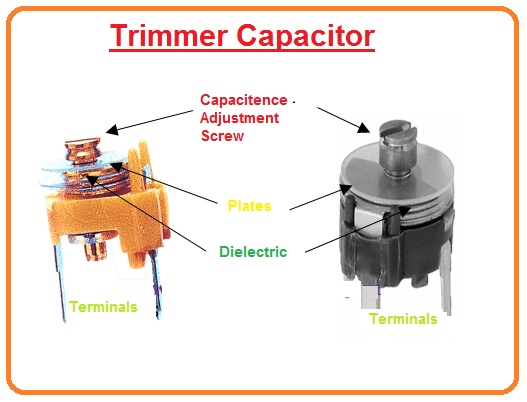

Trimmer Capacitor

- Trimmer capacitors are nonpolar. These capacitors are used in such applications where after installing of the capacitor there is no need to change capacitance.

- In this capacitor, the insulating material is fitted among the two parallel conductor plates.

- Normally, the capacitance of this type of capacitor changes by varying the distance among the plates.

- The trimmer capacitor has insulating material of mica, mylar, etc.

- Its capacitance values is some pico farad to two hundred picofarads.

- Trimmer capacitors are used to control the less to medium voltages and it is very competent.

- For a variation of capacitance of these capacitors always avoid use of matters that will damage capacitance.

Air Capacitor

- These capacitors are also nonpolar mutable. the capacitance of such a capacitor is very small around a hundred picofarad to one nanofarad.

- This capacitor has air among two plates which work as the dielectric material.

- The working voltage for these capacitors is from 10 to 1000 volts. The failure voltage of air as an insulator is lesser henceforth there is an alteration of electric failure in a capacitor.

- These principles to defective waged of a capacitor. Henceforth occasionally space is formed among capacitor plates which has K values approximately similar to air.

- The failure voltage is high for space hence lesser fortuitous of electric failure.

- The air capacitor is also named as Gang capacitor. These capacitors are a mixture of two or more mutable capacitors surfaced on a shared shaft.

- This alteration permits concurrent alteration in the capacitance of assembled capacitors.

- We can observe in the diagram that the gang has numerous output points.

- Such capacitors are used in amplitude and frequency modulation radio circuitries.

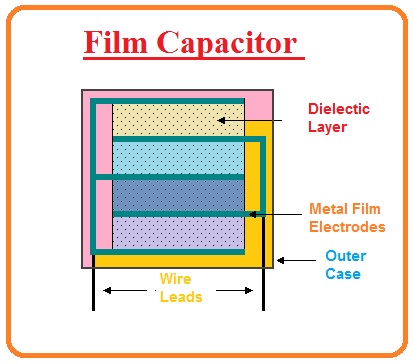

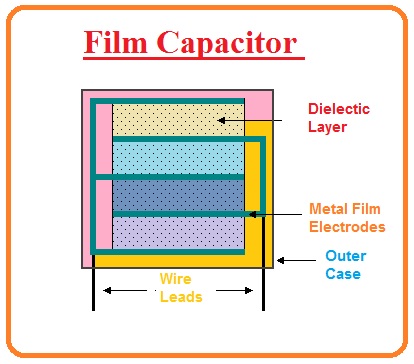

Film Capacitor

- These capacitors are very easily obtainable capacitors of all kinds of capacitors.

- Film capacitors have numerous categories of capacitors which are different in insulating or dielectric features. Which are Myler, Teflon, metalized paper, etc.

- Depending on voltage ratings these capacitors exist in five picofarads to 100 microfarad capacitance ranges.

- There are different dimensions and shapes in which this capacitor exists.

- Polystyrene, polycarbonate, or Teflon kinds of film capacitors are also known as plastic capacitors.

- The structure of plastic film capacitors is like that of paper film capacitors but it uses a plastic sheet in place of paper.

- The chief benefit of plastic film capacitors related to permeated paper categories is that they work well under higher temperatures, have fewer forbearances, long working life, and have higher consistency.

- Examples of film capacitors are rectangular metalized sheets and cylindrical sheets.

Electrolytic Capacitors

- Such kinds of capacitors are mostly used for such applications where higher capacitance is required.

- In this capacitor in place of using a very shrill metal film sheet coating for one of the probes, a partial fluid electrolytic solution in the shape of gelatin or gum is used which works as the 2nd electrode known as the cathode.

- The insulating instance is a very shrill sheet of oxide that is fully-fledged electrochemically in manufacture with the width of the sheet less than 10 microns.

- This isolating coating is so tinny that it is likely to create capacitors with larger values of capacitance with a smaller dimension as the distance among the plates, is very short.

- Most electric capacitors are polar, which means while applying DC to these capacitors always connect positive with positive and negative with negative terminal if you don’t so it will cause heavy short circuits and will be dangerous for your devices.

- Every polar electrolytic capacitor has clear marks of the positive and negative signs always follow these signs before applying voltages.

- These capacitors are mostly used in DC circuits as these capacitors have higher capacitance and smaller dimensions, so they are used to reduce the ripple and used for couple and decouple submissions.

- One chief drawback of electrolytic capacitors is their comparatively lower voltage ratings and due to the polarization of the capacitors, they are not good for AC circuits.

Read also:

- What is the Difference Between: Ceramic vs Electrolytic vs Tantalum Capacitors

- Introduction to Ultracapacitors, Construction, Applications

- How is a Microprocessor Different from an Integrated Circuit

- What is a Capacitor Polarity – Construction, Its Types, Function & Applications

- Difference Between Capacitor and Inductor

- Introduction to Capacitor

Faqs

- Capacitors are divided in two mechanical types Fixed-capacitance devices with a constant capacitance and variable capacitors.

- Variable capacitors are trimmers, that are adjusted during circuit calibration and device tunable during the working of the electronic instrument.

- The capacitors are used for storing energy, that can used with devices for power outages if there is a need for more power. Capacitors are used for blocking DC after getting fully charged and allow AC to pass through circuit of a circuit.

- The different types of SMD capacitors are tantalum SMD capacitors, Multi-layer ceramic SMD capacitors, Electrolytic SMD capacitors, etc. Tantalum SMD capacitors come with different values of capacitance that are higher than can get with the use of ceramic capacitors

- Class 1 ceramic capacitors provide the highest stability and fewer losses. They come with high tolerance and accuracy and are stable with variations in voltage and temperature. Class 1 capacitors are best to use as oscillators, filters, and needed audio applications.

What is the SI unit of a capacitor?

- The Farad is unit capacitance in the SI system. it defines the features of material to hold an electric charge. The value of capacitors is defined as farads, microfarads (µF), or nanofarads (nF)

- The capacitor symbol denoted the physical capacitor component. it is made with two parallel lines or plates, showing two conductive plates in a physical capacitor. These plates are separated with non-conductive material called dielectric.

- The capacitor is the main component in electronics and is used in different applications. Common uses of capacitors is energy storage, power conditioning, noise filtering, remote sensing, and signal coupling/decoupling.

- Supercapacitors are best for short charge and discharge cycles. They needed high currents for fast charging also high voltage with larger numbers and has two uses automatic pallet shuttle and a fail-safe backup system

- A capacitor is made with two metallic plates and an insulating material called a dielectric. metallic plates are put close to each other, in parallel combination but dielectric is between plates to ensure some distance. The standard capacitor is a sandwich of two metal plates separated by an insulating dielectric.

First-class information it is without doubt. My teacher has been searching for this tips.

Thanks for a nice share you have given to us with such an large collection of information. Great work you have done by sharing them to all. Simply superb.

I would prefer to thank you for the efforts you might have produced in writing this post. I am hoping the same very best perform from you within the long run also. In fact your inventive writing skills has inspired me to start my personal BlogEngine blog now.

My sister saved this web publication for me and I have been reading through it for the past couple hrs. This is really going to aid me and my friends for our class project. By the way, I like the way you write.

Very nice blog post. I definitely appreciate this website. Keep it up!

really huge variety of capacitors are available!!!