Hello, readers welcome to the new post. Today we will discuss the Heat Sensor Circuit. The heat sensor is an electronic component that is used to measure the temperature changes in the environment and transform this data into digit form and display it on the screen. There are different types of temperature sensors used, some of them have a direct connection with measuring objects to get the temperature details and some get the temperature in directly without a connection.

Hello, readers welcome to the new post. Today we will discuss the Heat Sensor Circuit. The heat sensor is an electronic component that is used to measure the temperature changes in the environment and transform this data into digit form and display it on the screen. There are different types of temperature sensors used, some of them have a direct connection with measuring objects to get the temperature details and some get the temperature in directly without a connection.

Commonly used temperature sensors are RTD, thermistors, thermoplastic, and ICs. In this post, we will discuss the circuit of heat sensors and learn the internal operation of that module. So let’s get started.

Introduction to Heat Sensor Circuit

- The heat sensor consists of a temperature sensor circuit. This module informs about temperature changes through an LED flash or alarm sound. Its operation is like a warning alarm system such as a smoke detector alarm.

- The resistance temperature or thermocouple converts the electric signal to Celsius temperature readings. Temperatures sensors are very commonly used in offices, homes, and buildings.

- These sensors are now compulsory to employ at congested places where high circuits exist to detect any faults exist there and these sensors can also be used for security system

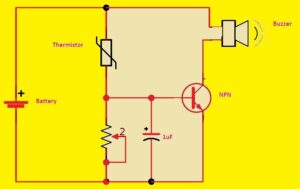

Heat Sensor Circuit Explanation

Circuit Components

- The components used in this circuit are listed here

- NTC Thermistor

- Transistor

- Buzzer

- Capacitor

- PCB from PCBWAY

Circuit Working and Construction

- After getting the required component for the circuit now discuss the construction and working of the circuit. In this circuit, there is the main component BC547 which is an NPN transistor used that is working as a switch. With the changes in temperature transistor provide the on signal to the buzzer and when the temperature is decreasing it will off the buzzer.

- In the circuit, you can see that there is an NTC thermistor of value 2.2K is attached to variable resistors and transistor base pin. So thermistors and variable resistors are working as sources of power for transistors. The value of the variable resistor controls the temperature high point that can be detected. In circuit, buzzer is attached to the battery and collector of BC547

- If there is no change in temperature thermistor has a high value of resistance for the transistor to get biased when temperate is increases the resistance of the thermistor reduces and gives a signal to a transistor that is working as a switch and in result transistors on the buzzer to inform about the high temperature.

Heat Sensor Circuit Functional Testing

- So friends after the creation of the heat sensor circuit on PCB board if you have any problem in the circuit there is a need of some technical help to find those errors. So there is the best in all services that provide PCB-based services and also have technical experts to find the faults existing in the PCB assembly and circuits mounted on board. That PCB supplier and expert in the PCB field is PCBWAY. PCBWAY is china based PCB supplier that provides a one-stop solution for all PCB services. So if you need PCB function testing service must visit them. PCB function testing is the main phase prior to the integration of these boards into complete systems. As part of their ISO9001:2008 quality management system PCBWAY provides three phases of PCB inspection of all types of assemblies prior to PCB testing.

- PCBWAY offered the PCB function tests listed here

- 1. Visual inspection after SMD Process

- 2. Free AOI Testing

- 3. X-ray Testing for BGA package, Function Testing, etc with extra charges.

- 4. Final visual inspection

- PCBWAY has the ability to provide functional testing for your PCBs. These tests make sure that the PCB created from them has good working conditions. Functional tests find all faults in PCBs.

- These tests are normally done after the circuit board is created and AOI and visual inspection are finished. Initial testing helps to find and remove component failure, assembly faults, and potential design errors at the initial phase and enhances troubleshooting fast.

- users can deliver good products to their clients in small time intervals. Functional testing helps to minimize the different errors like short circuits, open circuit missing elements, and incorrect parts connection

- Functional testers normally use computers attached to testing points or test probe points to do the FCT. They find that if the board clears or fails based on test results that are not according to certain requirements through operating software.

- The testing techniques used to find all outer analog and digital inputs and outputs with any existing LED that are tested for current movement, color, and intensity. In addition, the developed fixture allows test points to be connected to the PCB, which enables the testing of functions that are not available on the main connector.

- Functional testing is done through testing software, like firmware, and testing instruments like digital multimedia, input/output PCBs, and communication ports. Automated computerized functional testing (FCT) is performed by assembly line operators who use test software that interfaces with external instruments to monitor the devices under test.

- PCBWAY’s testing engineers will review your need like test scope and test instructions designing the test jig, adjusting the instrument and making the test report form, and designing the testing workflow

Type of Heat Sensor

- There are two main types of heat sensors.

- Fixed temperature heat Sensor

- Rate of a rising heat sensor

Fixed temperature heat Sensor

- In this sensor, two heat-sensitive thermocouples uses for the transfer of heat one for heat transfer that operates on radiation and convection process, and the second for measuring the heat from the environment.

- The heat sensor will operate irrespective of initial temperature and temperature changes from 12˚ to 15˚F on one minute.

Rate of a rising heat sensor

- It does not work for low heat values that come at starting of a fire. Its temperature element work when temperature reaches to a fixed value that is 58 centigrade

Advantages of Heat Sensor

- Some advantages of heat sensors are discussed here

- It has an easy configuration to provide the output of temperature measured

- It provides accurate results

- Response time is fast

- It is not affected by any medium

Applications of Heat Sensor

- it is used in heat cooling and heating systems

- It is used in different devices like washing machines, toasters, etc

- It used in industries to control the machine temperature

- Used in motors to save motors from overheating

That is all about the Heat Sensor Circuit all details has explained if you have any questions ask here. Further for any PCB-based problems and PCB services must visit PCBWAY that will provide you all solutions of your problems