Hello friends welcome to the new post. In this post, we will have a detailed look at Why Are There Holes In Plugs? Plugs are commonly used components of our daily life. Life-based on plugs for connecting the electrical devices to a power supply, like power connection with phones and other devices used. If you see that plugs come with small holes or slots think about the purpose of these holes. In this post, we’ll discuss the different types of plugs that have holes. So let’s get started why are there holes in plugs

Introduction to Plugs

- It’s important to explain the basics of a plug before discussing the causes of plug holes. The plug is an electric device that connects electric devices or instruments with a supply. it operated as like interfacing between devices and power sources helping the current flow to different connected devices

Design of Plugs

Body of the Plug

- The inner electrical connections are positioned in the body of the plug, which is made of insulated material like plastic. It works as a protection, avoiding unintentional contact with active electrical components. The plug’s body also gives it stability and structural integrity.

Prongs of the Plug

- The metal pins that connect plugs with the outlet are called prongs. Electrical connections in the socket are directly connected to prongs. The prong completed the circuit by offering current from the power source to the devices connected. The prongs’ construction integrates the holes seen in plugs.

Why Are There Holes in Plugs?

Plugs with holes do different operations from safety measuring to industrial uses. Let’s look at what causes that Why Are There Holes in Plugs?

Safety Measures and Grounding

- Holes in plugs are used to offer electrical safety. Electrical devices can be grounded with these holes

- Due to the malfunction or electrical surge, grounding makes a secure path for current to flow in the ground. The holes in plugs are configured with ground points in the socket when the device is plugged into the outlet with ground operation, carefully rerouting any extra electrical charge. follow for more updates solar system diagram

Heat Dissipation and Electrical Insulation

- Heat dissipation is also the main factor in using holes in plugs. The holes in the plug prongs cause the dissipation of heat that electrical devices produce when in use. The perforations increase the plug’s overall safety by venting heat and avoiding overheating.

- The holes in plugs also help in electrical insulation. A short circuit or electrical arcing is less exits because of the insulation effect of the air around the prongs in the holes.

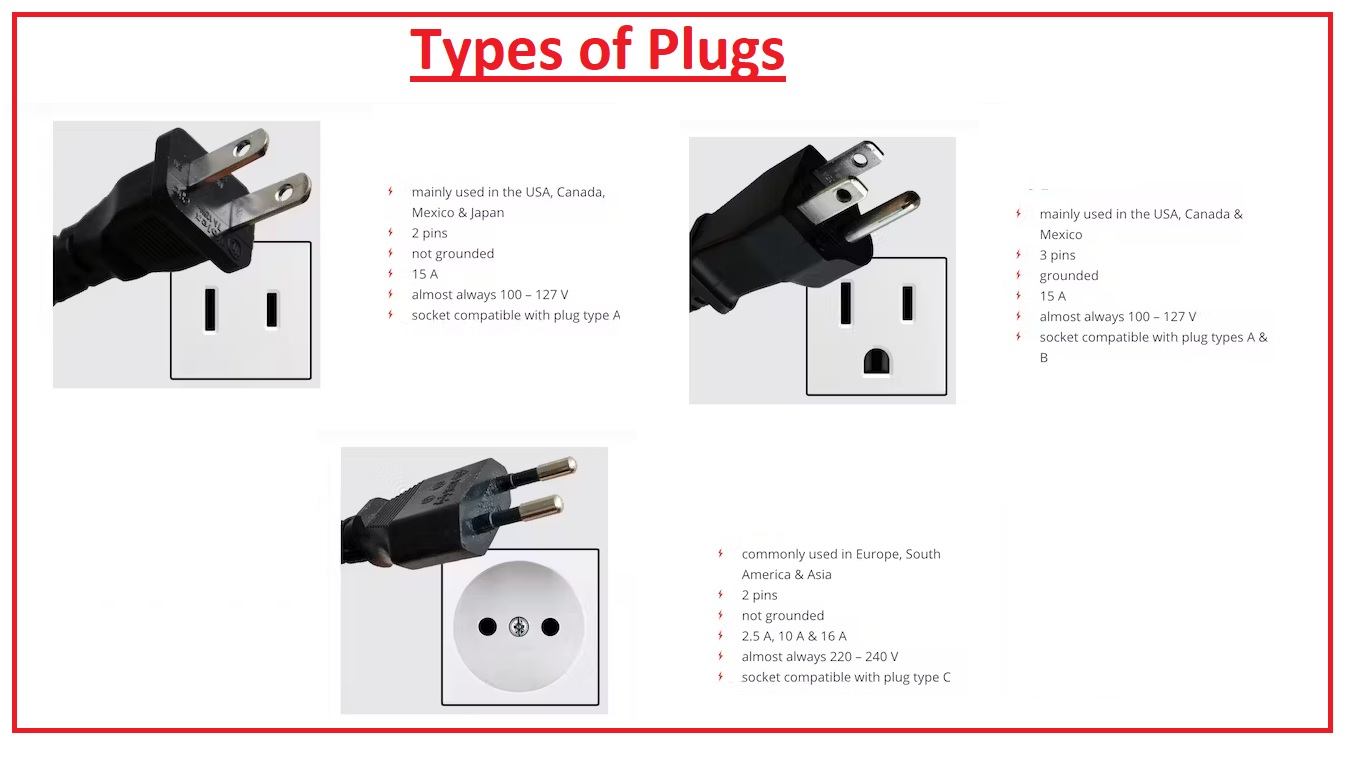

Types of Plugs with Holes

There are different types of Plugs with holes explained here

Grounded Plugs

- Three prongs made grounded plugs, called three-prong plugs. Two of the prongs are flat, while the 3rd one is rounded. The grounding prong is circle-shaped and frequently has a hole in it. This hole enables the connection to the electrical socket’s grounding terminal, making sure of correct grounding.

Polarized Plugs

- Two prongs on polarised plugs come in different sizes, one has a wider size than the other. The neutral prong is larger than the hot prong, which is thinner. Prongs on polarised plugs have holes for grounding and insulation.

Three-Prong Plugs

- Grounded plugs are comparable to three-prong plugs, known as grounded plugs, however, they come with different prong layouts. These plugs have two flat prongs for the hot and neutral connections in addition to a distinct grounding prong. For help in grounding and electrical insulation, three-prong plugs have additional holes on the grounding prong.

Related: What is Double Pole Switch & its Working

Benefits and Limitations of Plugs with Holes

Electrical Safety

- Hole-equipped plugs are those that have grounding features, that improve electrical safety. The user and the electrical equipment are both protected by grounding, which helps to avoid electrical shocks. These plugs limit electrical dangers by diverting extra electrical charges to the ground.

Compatibility and Versatility

- plugs like grounded and polarised plugs, are created to work with certain types of electrical outlets. It reduces the chance of loose connections or inconsistent power supply by ensuring an accurate and secure connection. With that, plugs with holes can be used in different electrical systems because of their adaptability, providing a standardized method for making connections.

Hazards and Risks

- Although plugs with holes have different advantages for safety, it’s compulsory to avoid any dangers and hazards. Plugs with holes may not provide sufficient electrical safety if improperly utilized or if the grounding function is impaired. It is the responsibility of the user to make sure that the electrical outlets they are using are accurately grounded and best for the plugs they are using.

Why do Plugs have Two Hole?

- Because they enable us to connect devices with power supply, plugs are the main part of electrical systems. A conventional plug has two holes, as can be checked if you look at it closely. For the safe and effective operation of electrical devices, these holes perform different functions.

- The prongs of a plug, which connect the devices to the electrical outlet, fit into the 2 holes in the plug. Every hole is related to a certain plug prong. Let’s explain the functions of these gaps:

- Hot Prong Hole: The hot prong fits into one of the holes of a plug. It delivers current from the supply to the devices. It is called the hot prong since it conducts electrical energy and is usually black or red colored to make it easier to identify. The hot prong’s hole confirms a solid and dependable connection between the plug and the outlet, helping the current flow without interruption.

- Neutral Prong Hole: The neutral prong goes in the second hole of a plug. By returning the current from the device to the power supply, the neutral prong completes the circuit. It is called a “neutral” prong since it is low voltage and is usually white or blue in color. The neutral prong’s hole assures a secure connection and provides the current’s return channel.

What About Plugs with Blades the Same Width?

Some devices can plugged in any direction due to the same width of both blades on the plug. It can be unsafe for AC power lamp, or devices that need DC to invest incoming power from the wall before it is used in the first place. These devices operate the AC power of a circuit called an inverter for creating DC power then used by the device.

As AC curent change polarity electric current passes in both directions, so it does not matter which prong charger gets power. Since it is done through a rectifier circuit, it is converted into a DC curent so there is no chance of harm to plugging it with a prong in any hole of plug

Read also: What Is Double Pole Single Throw Switch

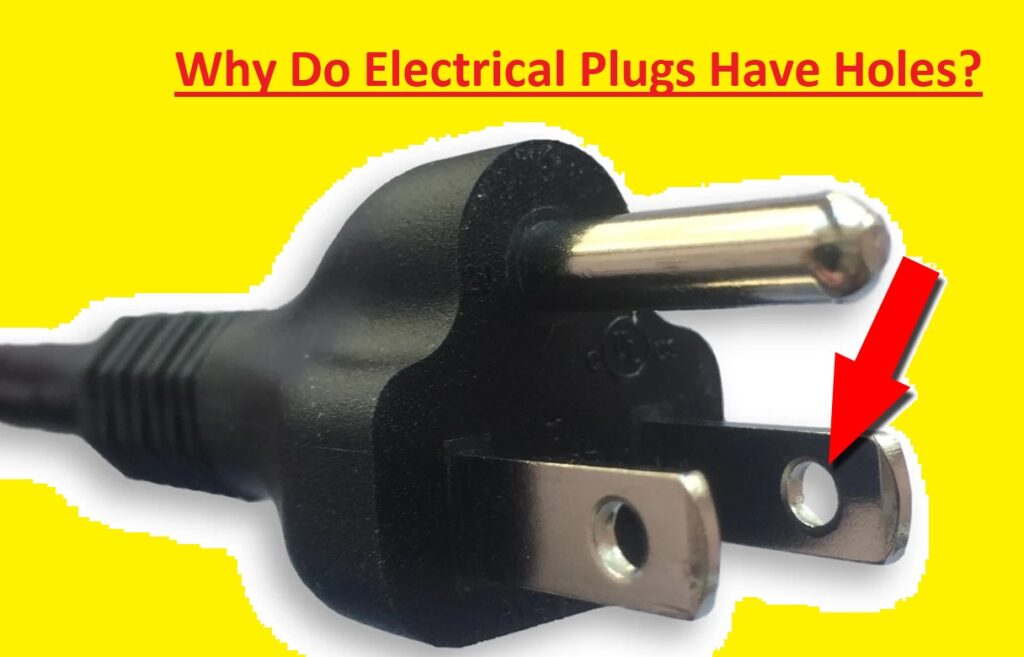

Why Do Electrical Plugs Have Holes?

- Safety and Grounding: Electrical plugs’ holes are used to assure safety, especially through a process called grounding. In the case of a malfunction or electrical surge, grounding provides a secure path for electrical current to pass into the ground. The prongs of the plug can be configured to the grounding terminals in the electrical outlet through the holes in the plug, making a secure grounding link. The safety of the user and the connected electrical devices is ensured through the grounding feature, which helps to avoid electric shocks.

- Heat Dissipation: When operating, electrical devices produce heat, which plugs’ holes help to dissipate. These perforations improve airflow in the plug and around the prongs, which provides effective cooling. The holes do heat dissipation, which minimizes the danger of harm to both the plug and the electrical devices it is attached to by preventing the plug from overheating.

- Manufacturing parameters: Electrical plug manufacturing also applies to the holes. These holes enable the effective injection of insulation into the plug body during the molding or manufacturing process. The plug and electrical outlet are configured accurately and securely as a result. The plug becomes stronger and more resistant to wear and tear due to the holes’ contribution to the plug’s overall structural integrity.

- Electrical Insulation: Electrical plug holes have aired around the prongs that work as insulation. This decreases the possibility of electrical risks by preventing electrical arcing or short circuits. Plugs with holes provide effective electrical insulation, ensuring the secure flow of power.

Why Do Some Homes Have Two-Prong Outlets?

Outlets at homes made before the 1960s come with two prongs. As they are not the grounding category, according to NEC they can be used if used in the right way. We can check the two-prong outlet with a circuit tester to make sure it is safe to operate for small devices used at home.

The 3 pronged connection plug cannot used with two-prong receptacle outlets. So not brake grounding prong off 3 prong connection plugg. It can cause serious issues.

What Does the Third Outlet Prong Do?

Some plugs come with 3rd small and semi-rounded prong connected at the lower end of the plug, in the middle of two blends. 3rd prong is used for grounding and it has features.

- The ground circuit is connected with the neutral circuit at the home breaker box, making a safety valve for the electrical system

- if a short circuit occurs in the device, the ground prong makes the path of low resistance that power is used to main electrical panle and then in the ground through the electrical service’s grounding system.

Who Invented Holes in Plugs?

- The development of plug holes is not credited to one person. Plugs having holes have been used for different functions and in different conditions throughout history.

- Many engineers and innovators who worked on the development of electrical systems are responsible for the invention of current plugs and sockets as well as their standardization. The Main Man, Thomas Edison, in the late 19th century, developed an electrical distribution system that resulted in his take on an electrical socket and plug design.

- There are many reasons why plugs have holes. To provide grounding in the case of electrical plugs, holes are used. This helps to avoid electrical shocks and ensure adequate electrical safety. Depending on the countries and electrical standards in use, many plug designs and grounding holes are used.

- It’s necessary to note that the idea of plug holes applies to more than simply electrical applications. For example, certain plugs used for other purposes or in other areas can have holes to allow for extra parameters like ventilation or fluid flow. Based on the exact application and required functions, the design and use of plugs with holes can changes

Do All Electrical Plugs Have Holes?

- No, not every plug has a hole in it. Electrical plugs can have holes or not, on the base of their construction and use. Plugs have different designs throughout the world, although numerous modern electrical plugs do feature holes, for grounding purposes.

- Electrical standards and plug types can be different in the form of shape, design, and the presence of holes according to different locations and areas. A plug could have two or three prongs without any holes, for example, whereas another can have prongs with or without grounding holes. Also, plugs used in particular sectors or for specialized applications may have unique designs and characteristics, like holes for particular purposes.

- During the discussion of the layout and characteristics of electrical plugs, it is important to consider national and regional electrical standards and laws of the area you are talking to.

What is a 3-prong plug called?

The 3 pronged receptacle is called the grounding receptacle. Contrary to two-prong receptacles, 3 prong receptacles are connected to the ground to protect electrical devices that is connected to damage in a result of short circuits.

What is a 2-prong plug called?

it is called Nema 1-15 if it was made by Harvey Hubbel II, 2 pronged plugs are called Type A plugs. These types of underground plugs are commonly used in North and Central America.

Which side of a 2-prong plug is positive?

As there is AC used prong does not have a specific positive or negative side. But two prongs have hot and neutral sides. The wider prong connects with a neutral wire and the small prong with a hot wire.

What happens if the third prong breaks?

If any one prong or wire get dislodged, curent not flow in the device. It can affect the devices.

What is the purpose of plug-hole

It prevents the plug from pulling out of the socket from the weight of the plug or cord. It helps to enhance contact between the plug and the outlet. Some devices also have factory sealed or locked out.

Why do electrical plugs have two prongs?

FAQs

Q1 -Do all plugs have holes?

No, plugs do not all have holes. Plugs with holes can be in three-prong, polarised, and grounded plugs.

Q2- Why are plugs with holes considered safer?

Due to the possibility of grounding, which casues the effect of electrical shock and directs high electrical charges to the earth, plugs with holes are safe

Q3- Can plugs without holes be used safely?

As long as they follow safety rules, are compatible with the electrical system, and are grounded accurately, plugs without holes can be used without risk.

Q4- Do plugs with holes work in all countries?

The electrical systems and standards in each country determine whether plugs with holes are supported. It can be necessary to use adapters or converters when using plugs with holes in different nations.

Q5- Can we modify a plug without holes to have holes?

It is not suggested to modify plugs without holes since doing so affects the plug’s integrity and safety. It is good to use plugs that are created with the correct holes for the job at hand.

Explore Our Coins Articles: