Hi, friends in this post we will have a look at what Size of Wire I Need for a 100 Amp Sub Panel. The 100 amp sub panel wiring needed is 4 AWG for copper wire and 2 AWG for aluminum wires. In this post, we will have a look at the installation of a 100 Amp sub-panel accurate wire size used for it. Let’s get started with 125 amp wire size.

Introduction to 100 Amp Sub Panel

- The 100 amp circuit breaker is best to deliver power to a 2 bedroomed house. Larger homes with 200 amp breaker boxes or higher that need more voltae can use 100 amp subpanels.

- Wire sizes are defined in AWG and come with copper or aluminum wires in different thickness values.

- The 10 amp sub panel installation needed 4AWG copper wires or 2 AWG aluminum wires.

- Aluminum is mainly used for service entry wires since it is low cost and less weight.

100 Amp Wire Size

Base don contract to utility service capacitor amper can be about 100 amps and be about 100 amps. The 100 amps service is bare currently. There are two service entrance conductors needed one set in the Drip loop and met base and the other between the meter base and the main service panel.

The 3 common types of conductors used are copper, aluminum, and copper-clad aluminum. Based on the conductor, 100 amp wire size can be different.

| Wire/Conductor Size for 100 Amp Service | ||

| Copper | Aluminum | Copper-Clad Aluminum |

| AWG 4 | AWG 2 | AWG 2 |

| AWG 4 | AWG 2 | AWG 2 |

Introduction Service Panel

There are two main features of the electrical service panel

- The main panel is the main disconnect breaker, 100 amps here is a service panel

- The distribution panel is a circuit breaker panle with a complete circuit load that is connected in the garage.

In older type homes we can see the main service disconnect and breaker. Currently, mostly the main disconnect is connected outside and the distribution panle in the house.

Mostly there is a single circuit breaker at the meter, that is main breaker, and one or more distribution panels are connected.

Based on the electrical panel installation we can find the main service panel and disconnect circuit breaker on top or lower, according to service wire feeds from overhead or underground. It is best to know that the main service panel comes with main disconnect.

The main service panel is bonded. The subpanel is not bonded and comes with two hot wires, one neutral wire, and a bare copper wire for grounding.

A servie panel is a distribution point that connects incoming main service wires to outcoming wires, which are used for distributing current to differnt parts of the house.

A circuit breaker panel is not like a fuse box since it comes with mechanical, toggle switch breakers, not fuses, but its functions are the same.

Older fuses pull in and out then of rocker style connection and removing circuit breakers.

Parts of the electrical service panel

- Swinging hinged door that used to access switches.

- protective cover for accessing to technical part of a panel

- Two cables that get power from outside.

- Open or shut spaces for additional breakers.

- Assortment of wires

Sub Panels

The 100 Amp wire size comes with 3 wire cables comes with 3 insulated conductors and bare copper ground. In some homes, there is 100 amp service on secondary service panels, that called sub-panels.

Most homes have master service panels that get power from municipal hookups and secondary panels fed by the master panel.

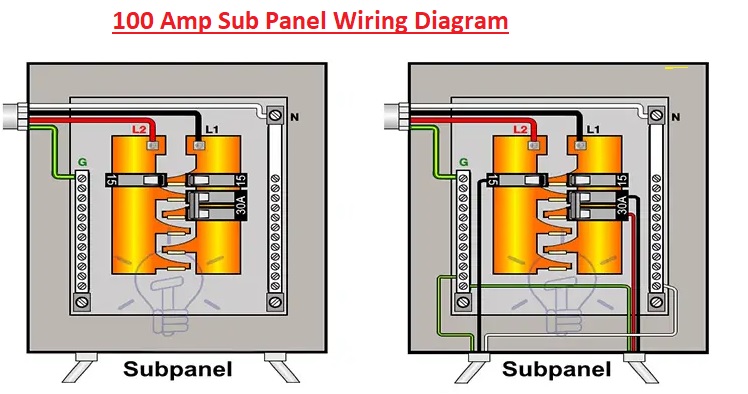

100 Amp Sub Panel Wiring Diagram

The wiring diagram for a 100 Amp subpanel is explained here

- There are differnt methods for wiring the 100 Amp Panel. But the best option for wiring is to get services for electrification.

How to connect Sub Panel

- During the installation subpanel first of all feeder cable connects to the subpanel from from panel. The 3-wire cab has 3 conductors and the bare copper ground wire is used. For the 100 amp sub panel there are #4 copper wires or #2 aluminum wires used

- Now connect two hot wires from the feeder cable to lugs at the live bus bar of the subpanel, make the connection of neural with a neutral bus bar and bare copper wire attached to the ground bus bar

connection with the Main Panel

- Now connects hot feeder wires with new 240 volts circuit breaker a main panel and ehn connects with neutral wires from feeder cable to required bus bar in the main panel. It also connects the feeder breaker in the main service panel with an open double-slot

Related: What Size Wire Should I Use for a 50 Amp Sub Panel?

How Many Breakers Can I Put in a 100 Amp Panel?

The highest number of breakers we can connect in a 100 amp panel is based on the design of an electrical panel, that helps to connect circuits on the panel.

The standard 100 amp panel normally supports 20 circuits which is equal to 20 circuit breakers.

The NEC defines that a 100 amp panel has features to handle about 42 breakers maximum. It is a theoretical feature but there is a need to know the practical capacity of the panel.

According to NEC guidelines individual circuits and breakers in 100 amp panes do not exceed 80% of the capacity of a panel, this 100 Amps in these conditions.

How Much Electrical Load Can a 100 Amp Panel Handle?

- For finding the electrical loads that a 100 amp panel can handle, it is important to note that the net current in all main service panel breaks does not cross 80 percent of panel capacity, that is here 100 amps.

- Suppose 100 amp service from utility and 100 amp main breaker panel, and we can connect any special breaker to high-power devices like ovens, dryers, and air conditioners.

- Such as 20 amp circuit breakers have a feature to handle a high load of 2400 Watts at 120 Volts.

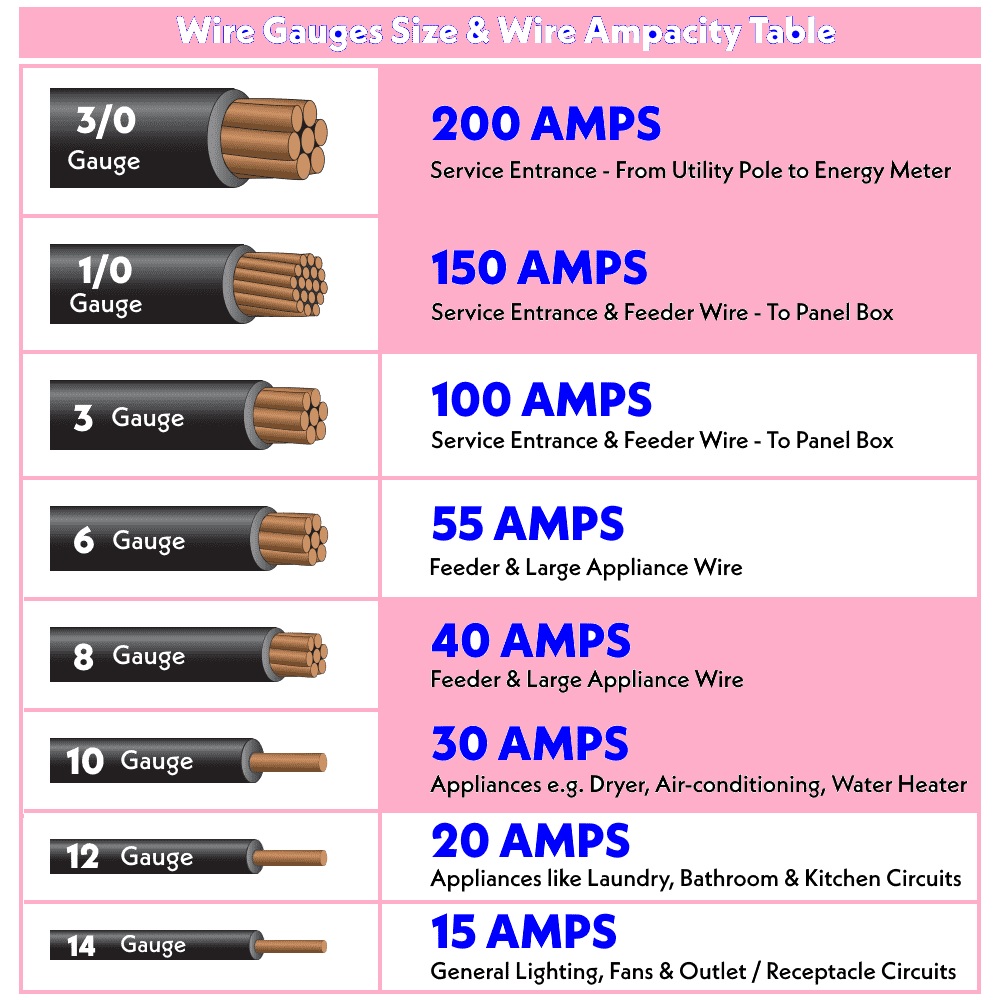

100 amp wire size chart

What Size Wire is Good for 100 AMPs?

Normal wire size for 100 amp service is 4 AWG or 2 AWG for copper wiring and 2 AWG, 1 AWG, or 1/0 AWG for aluminum or copper clad wiring. it is used for direct burial.

During the selection of the 100 amp service wire size note that a 100 amp circuit at 240 volts can process about 24,000W of electricity.

If wire runs for longer distances, like more than 100 feet, use large sizes according to voltage losses.

Ground wire sizes for 100 amp service are not the same, normally 8AWG copper grounding wire or 6 AWG aluminum grounding wire.

What Size Pipe Do I Need for 100 AMP Sub Panel?

conduit size for a 100 amp sub panel based on these factors.

Wire Size:

- The wire needed for the 100amp sub panel is about a 2 gauge non-metallic sheathed electrical cable. This wire size has features to carry a full 100 amps of current.

Conduit Type:

- The commonly used conduit type for electrical installations is PVC conduit. PVC conduit is longer lasting, easy to afford, and can easily work

Conduit Fill:

- The NEC codes define the highest fill capacity for conduits based on size and wires connected. it is good to make sure that the conduit is not overfilled, since it can resulting overheating and other safety features.

Conduit Size:

- According to the above discussion, the here conduit size for the 100 amp sub panel is explained.

2-inch PVC conduit

- It is commonly used in 100 amp sub-panels and offers enough space for 2 gauge wires.

2 1/2-inch PVC conduit

- This size can used for a 100 amp sub panel, But it can be difficult to operate with and can not be requried until there are many turns or other specific installation requirements

125 amp aluminum wire size

The aluminum wire size for the subpanel is based on the distance from the main breaker panel.

- 1/0 AWG aluminum wire for a 125 Amp subpanel used for 100 feet distance

125 amp wire size chart

| Wire Size | Copper Wire Dia | Copper Wire Dia |

|---|---|---|

| 2/0AWG | 0.365″ | 9.27 mm |

| 3/0 AWG | 0.410″ | 10.41 mm |

| 4/0 AWG | 0.460″ | 11.68 mm |

Wire Size For 100 Amp Sub Panel 100 Feet Away

For different distances, voltage losses occur. This loss is not important at low distances but for longer distances such as 50, 100, 150 feet voltage losses are important and will be considered for it. For measuring voltage loss for 100 amp increase the ampere.

- First of all, needed to apply 80% NEC code rule.

- Measure the 20 percent voltage loss due to flow to 100 feet distance.

For measuring ampacity check 80 percent NEC code at zero fett distance 100amps needed. These 100 amps must be 80 percent of the ampacity of the wire. If 100 amps is 80 percent that wire size is

Min. Wire Ampacity = 100% × 100A / 80% = 125 Amps

So we needed wire of 150 ampacity to send 100 amp service 100 feet away.

Wire Size For 100 Amp Sub Panel 150 Feet Away

Wire Ampacity (150 ft away) = 125A × 1.3 = 162.5 Amps

There is a need for a wire with 162.5 ampacity to send 100 amps current at a 150-foot distance.

Wire Size for 100A Breaker

Wire Ampacity = 100 Amps x 1.25 = 125 Amps.

Wire Size: #3AWG Cupper and (#1 AWG for Aluminum)

Where is 100 AMP Service Used?

It is based on the size of the home and the devices connected. The 100 amp service panle is for medium-sized houses and apartments that have 240 volts of devices connected such as AC systems.

100 amp service is not commonly used in larger size houses with electrical and gas devices connected that need high power. For this house, 150 amp or higher is needed.

10 amp service is not for houses more than 3000 square feet having AC. Some other uses of 100 service panle are workshops, garages, and temporary power supply.

Types of Copper Wire For 100-amp Service Panels

- THHN/THWN-2 and XHHW-XHHW-2 are used in conduit.

- USE-2 RHH RHW-2: It is used in underground service entrance devices

- Copper SER: It is used for panels and subpanels. Ensure to use a cable with the best ground size.

- Type MC cable: It has protective armor and is used without conduit

- UF-B cable: It is used for underground service and as a direct burial cable.

Types of Aluminum Wire For 100-amp Service Panels

- 2-2-2-4 Dyke Quadruplex Aluminum Conductor Underground Direct Burial 600V URD

- SER service entrance cable

- XHHW

- USE-2 (approved for underground service)

What size ground for 100 amps?

8AWG

What size wire for a 200 amp sub panel?

If you connect a 200 amp electrical service panle use copper or aluminum, wire conductors. The NEC suggests 2/0 AWG for copper wire or 4/0 AWG for aluminum or copper-clad wire for 200 amp sub panel

Will 6 gauge wire handle 100 amps?

What size wire is good for 100 amps?

What is the max breaker size on 100 amp service?

What size wire for a 100 & 125 amp sub panel?

| Copper Wire | Aluminum Wire | |

|---|---|---|

| 100A | 4 AWG | 2 AWG |

| 125A | 2 AWG | 1/0 AWG |

| 150A | 1/0 AWG | 2/0 AWG |

| 200A | 2/0 AWG | 4/0 AWG |

How many watts can a 100 amp sub panel handle?

The 100 amp 120/240-volt service can handle 24000 watts. according to NEC’s 80 percent rule, it can handle about 19000 watts or breakers totaling 80 amps.

Read Also:

- 30 Amp Wire Size: What AWG Wire You Need?

- 125 Amp Wire Size and Breaker Guide

- 60 Amp Wire Size – Which AWG is Best for 60 Amp Breaker

- What Size Wire for 100 Amp Service

- What Size of Wire Do I Need for a 100 Amp Sub Panel?

- What is 4/0 aluminum wire rated for?

- Socket Size Chart – Socket Sizes in Order from Smallest to Largest

FAQs

Q1: What happens if we use the wrong wire size for a 100 Amp sub-panel?

If the wire ampere capacity is less the ampere of load, the wire will overheat and cause a fire. If the ampere wire capacity is high then the load it not affected.

Q2: Can we use a smaller wire size for a shorter distance?

No, the wire is small size then recommended will not handle the amount of current safely resulting in overheating of the wire and causing fire.

Q3: Is it safe to use aluminum wire for a 100 Amp sub-panel?

#3 copper with a #8 ground will suffice for 100A. #1 aluminum with #6 insulated ground will be for 100A

Q4: Can we install a 100 Amp sub-panel myself?

Any electrical repair can be dangerous, but some people who have electrical experience can install subpanels byself. But it is suggested to get the services of an electrician.

Q5: How do we determine the voltage drop for my sub-panel installation?

- V=R*I, if the flowing current and the electric element’s resistance known

- V=P/I, if the power and electric current are known.

What size wire for a 100 amp sub panel?

Normal wire size for 100 amp service are 4 AWG or 2 AWG for copper wiring and 2 AWG, 1 AWG, or 1/0 AWG for aluminum or copper-clad wiring.

Can 4 AWG handle 100 amps?

wires for 100 Amp Service are 4 AWG or 2 AWG for copper wiring and 2 AWG, 1 AWG, or 1/0 AWG for aluminum or copper-clad wiring

How many amps can a 100 amp sub panel handle?

Ensure that 100 amp service and 100 amp panel do not exceed more than 80 percent of capacity. it means all single circuits and breakers must use about 80 amps in 100 Amp Service with a 100 Amp Circuit Breaker Panel.

What size breaker do I need for a 100 amp sub panel?

100-amp breaker size is best if you want to use the full 100-amps