Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will discuss What is Slip Ring. The slip ring is such a tool that make calms the transmission of the electric power and signal from the static network to the rotatory. It is used for any electro-mechanical network in which signal and power transmit due to rotation. A slip ring can increase mechanical performance, in a short network process and remove such wires which likely to damage.

Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will discuss What is Slip Ring. The slip ring is such a tool that make calms the transmission of the electric power and signal from the static network to the rotatory. It is used for any electro-mechanical network in which signal and power transmit due to rotation. A slip ring can increase mechanical performance, in a short network process and remove such wires which likely to damage.

Slip rings can deliver nonstop or alternating revolutions during the transmission power and data-shortening process, improving device performance, and removing the risk of damage to electric wiring among the moving portion. In today’s post, we will have a look at its working, construction, types and some other factors. So let’s get started with what is slip ring.

What is Slip Ring

- The slip ring is also known as the rotatory electric device, such as connectors that can rotate, spinners, or electric rotatory connections.

- This device is mostly used in wound rotor motors which is the type of induction motor, generator, AC networks, packing machines, cable rollers, and in wind generation turbines.

- This component is mostly used for rotary devices to the transmission of energy, used in control circuitries, and for analog and digital applications used in fluid dynamin instruments, rotatory beacons (A beacon fitted on the airports to specify the airports’ location to pilot during night time), telescopes which use radio waves, or heliostats (is such instrument which consists of mirror, when it rotates it reflects the light of the sun to the specified location).

- A slip ring is a technique that makes an electric linkage by rotatory connections.

- Officially, it is an electrical power transmitting module that permits the movement of power among 2 electric rotatory portions, like in a motor.

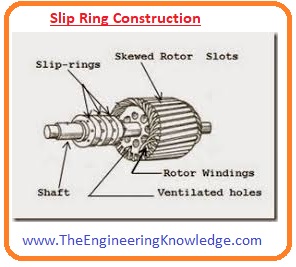

Slip Ring Construction

- Normally the slip ring comprises of the static graphite contacts (brush) which scrubs (rubs) on the external diameter of a revolving metal ring.

- When the ring of metal rotates the current or the electrical signal is transmitted to the ring by the static contacts.

- This simplest assembly has been used for years as a basic technique of flowing current into a rotatory instrument.

Slip Ring Types

- Many types of slips rings are described here.

Mercury-Wetted Slip Rings

- This type of slip ring is famous for its lower resistance value and fixed joining (connection) it uses many methods that swap the sliding brush connections with fluid metallic molecularly attached to the links.

- During rotary motion, the metallic fluid keeps the electric link between the static and rotary joints.

- Due to the use of mercury, we have to take some safe measurements, because it is a poisonous liquid.

- If this slip ring is working in such an environment where food production is happening the use of mercury should take some special precautions.

- Seepage of the mercury and the subsequent uncleanness could be very thoughtful.

- This slip-ring expedient is also restricted by temperature, as mercury coagulates at almost minus forty degrees.

Pancake Slip Rings

- This type of slip ring consists of many conductors which are assembled on the smooth disc-like concentric rings positioned on the rotatory shaft.

- Such type of arrangement is bulky and has a larger volume for similar circuitry, high capacitance and crosstalk, higher brush attire and further willingly gathers wear wreckage on its perpendicular axis.

- However, a pancake provides an abridged axial span for the many circuitries, and so can be suitable in some submissions.

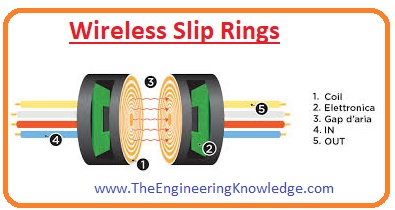

Wireless Slip Rings

- This type of slip ring does not use metal and carbon brush contacts to transmit power as this method is used in older slip rings.

- Instead, the wireless slip ring transmits power by the electromagnetic field, which is generated by the windings which are located in the rotary receiving point, and the statice transmitter device.

- Wireless slip rings are a more advanced form of slip rings, as it does not use conventional methods to transmit power so it is good for difficult working conditions and it ness less raping costs.

- But there is a disadvantage that it transmits less amount of power than other slip rings of a similar size.

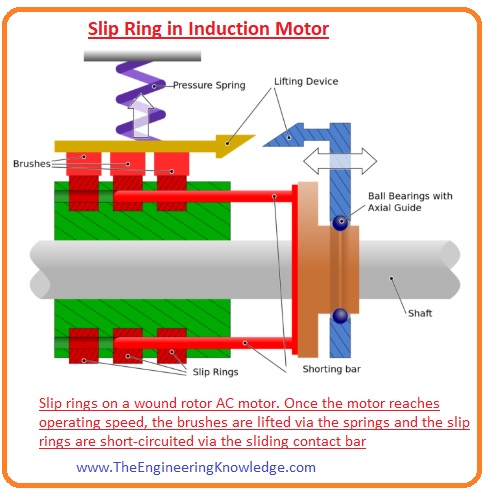

Slip Ring in Induction Motor

- The wound motor is the type of induction motor, it uses a slip ring to increase the resistance of the rotor windings not for the power transfer.

- The wound rotor used 3 slip rings which are constructed from copper or a lot of copper. These rings are connected to the shaft of the motor.

- These three slip rings are joined with the 3 phases with the roto’s windings.

- The slip rings are connected with carbon brushes to reduce friction. These brushes are connected with such devices which vary the resistance like a rheostat.

Alternative Names of Slip Ring

- There are many names of the slip ring-like commutator, collector ring, rotatory electric contacts, and electric slip ring.

- But its name commutator is mostly used for dc motors and generators.

- When it is used in higher speed or less friction application it is known as the rotary transformer.

Slip Ring Applications

- The slip rings are used in the rotating unit to work with the device, normally denoted as a rotating joint.

- The work which is done by the rotatory unit in the fluid is similar to the slip ring for the electric power.

- They are frequently combined into rotating units to transmit power and data to and from rotatory apparatus in combination with the medium that the rotating unit offers.

Difference between Slip Ring and Split Ring

- These are some differences between the split ring and slip ring.

| Slip Ring |

Split Ring |

| A slip ring is used to transmit power among the rotating and static parts of AC machines. | The split ring is used to change the polarity of the current in simple words for converting AC into DC. |

| It is used in ac machines like induction motors. | It is used in dc machines. |

| Its physical structure is similar to the complete ring. | It is part of one ring. |

| It provides an output of the alternating current generator to the ac motor. | It is used to provide sinusoidal voltage to dc motor. |

How Do Slip Rings Work?

The slip ring rotates at different speeds based on uses. The slip ring moves over the central shaft and sits on the base plate. The base plate or mount is static and the shaft rotates in the middle. It helps the slip ring to transfer power from the static system to a 360-degree rotating unit, completing the circuit.

Faqs

- The slip ring comes with static graphite or metal contact that rubs on the external diameter of the rotating metallic ring. When the metallic ring turns, current or signal conducted through the static brush to the metallic ring makes a connection

- Slip rings are used in high-end industrial equipment or accurate electronic devices like aerospace equipment, automatic processing equipment, smelting equipment radar communication equipment, medical equipment,

- The slip ring is an electromechanical device that helps power and signal to be transmitted from static to rotating structure. It can used in electromechanical systems where rotation is needed and transmitting power of signal.

- When the slip ring rotates roller on spring loaded arm follows the contours of the cam and actuates a small single pole, double-through switch. The accuracy of +/- one degree gets and is repeatable with design, and about 3 parts more thatn 360 degrees rotation with single cam.

- Split rings are connected with metallic clips and slip rings are connected with slots in the middle. Split rings are used where a strong connection is needed and slip rings are used where a flexible connection is needed.

- A slip ring is a closed ring and a split ring is divided in two parts or higher. Slip ring is used in ac motors for providing continous transmission power and signal,, and a split ring is used in DC motors for reversing the polarity of the current.

So friends that is the complete post on slip ring I have mentioned every parameter related to slip ring. If you have any questions about this post ask in comments. Thanks for reading. see you in another amazing post. Have a good day.

Right now it sounds like WordPress is the top blogging platform available right now. (from what I’ve read) Is that what you are using on your blog?