Hi reader welcomes another interesting post in this post. We will have a detailed look at PMDC Motor: Construction, Working and Applications, DC motor is such a motor that used dc power to generates mechanical power. its operation is such that when any current-carrying conductor is placed in a magnetic field force applied on the conductor due to interaction of this field and the conductor rotates.

Hi reader welcomes another interesting post in this post. We will have a detailed look at PMDC Motor: Construction, Working and Applications, DC motor is such a motor that used dc power to generates mechanical power. its operation is such that when any current-carrying conductor is placed in a magnetic field force applied on the conductor due to interaction of this field and the conductor rotates.

Here, the conductor is the rotor and the field is produced at the stator. That can be generated through the external supply current and can be generated through the use of a permanent magnet at the stator. Such a motor that has a permanent magnet at stator for field generation is called permanent magnet dc motor. In this post, we will discuss its working construction and some other factors. So let’s get started with PMDC Motor: Construction, Working and Applications.

Introduction to Permanent DC Motor or PMDC

- The PMDC motor is a type of dc motor which used permanent magnets at stators as poles. This motor has some physical dimensions similar to the shunt dc motor.

- Such as like the shunt dc motor it also not has an outer field circuit and field loss. Since it also not used field windings due to this it size is small compared to other dc motors.

- It is available in less fractional and sub fractional HP dimensions so it saves the cost of outer field circuitry.

- With these features, it also has some drawbacks. The magnet used in this motor does not generate large intensity Flux in this motor which can be generated in case of external field circuitry.

- So torque induced by this motor is less than the torque induced by the same size shunt motor. With that PMDC also provides a risk of demagnetization.

- Here point to notice that due to armature current in dc motor field in armature windings is generated.

- The flux generated by the armature field linked with the flux of poles at stator so at some point these flux cancels out one another and at some point supports each other due this net flux decreases.

- This process is called armature reaction

- In this motor the flux at poles is called residual flux as maximum parts is diminished due to the flux cancel out process.

- If the value of armature current is high then it can completely demagnetize the pole and deleted the flux at poles completely.

- Demaginization of flux can also occur due to heating produced by the large value of load linked to the motor.

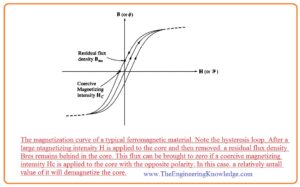

- In the below figure you can see the magnetization curve of ferromagnetic substances. This curve is between flux density and H magnetizing intensity.

- If high-intensity MMF is given to this substance and then eliminated there will some residual magnetism will Bres in this material.

- To completely reduce this residual magnetism we have to apply a field with reverse polarity to this material.

- For practical motor such material used at their stator and rotor that has a small value of Bres and Hc ( coercive magnetizing intensity).

- because this type of substance will have less value of hysteresis losses.

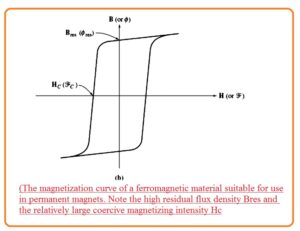

- While good material used for pole creation should have a high value of residual flux density Bres with that also have large HC.

- For this type of substance, the magnetization curve can be seen in the below figure.

PMDC Motor Construction

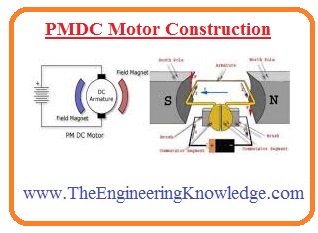

- In this motor permanent magnets is assembled at the steel stator having a cylindrical shape.

- While the rotor of this motor has armature windings with that commutator, slots for windings carbon brushes.

- Three types of permanent magnets is used in this motor that are Rare-earth magnets., Alnico magnets and Ceramic.

Working Of PMDC

- The field at stator at this motor is used through the permanent magnet, the direction of this field is at ninety degrees to field produced by the rotor.

- These two fields interact with each and torque is produced due to this torque rotor rotates.

So friends that is a detailed post about PMDC if you have any further query ask in the comments. Thanks for reading. Have a nice day.