Hello, readers welcome to the new tutorial. Here we will discuss the Importance of PCB IPC Standard. IPC is a trading company related to electronic modules. It set the different paramerts for well operation and use of any electronic devices with that related training research and different policies. It is consists of more than three thousand related companies all over the world. Its related companies offer the services related to designing, and board creation such as PCBWAY, as well as equipment providers.

Hello, readers welcome to the new tutorial. Here we will discuss the Importance of PCB IPC Standard. IPC is a trading company related to electronic modules. It set the different paramerts for well operation and use of any electronic devices with that related training research and different policies. It is consists of more than three thousand related companies all over the world. Its related companies offer the services related to designing, and board creation such as PCBWAY, as well as equipment providers.

This company started its operation in 1957 as a services provider of PCB board. In 1999 changed its name to IPC with tag of association connecting electronic industries. Its head offices are in Bannockburn, millions and sub-offices are situated in different countries such as USA, India, etc. Here we will cover the different basis for related to IPC and its importance for PCB-based companies.

Introduction to IPC PCB

- As IPC make the different parameters and standard for electronic and electrical engineering-based companies also make the different standard for PCB industries.

- These standards are easy can access at the different processing levels of manufacturing companies such as manufacturing process, designing, and assembly.

- In the case of PCB, manufacturing IPC is considered as the main factor like in Gerber file creation, PCB designing, and project creation.

- The material used for PCB manufacturing also fulfills the IPC standard also SMD components and surface finishing for PCB based on IPC

- Testing and quality of board are also based on the IPC standard.

- Electronic operation at the board and soldering also follow the IPC standard.

- Different manufacturing of PCB is carefully observed that their components are following the rules of IPC.

IPC Based PCB Suppliers

- There are different PCB suppliers working but the best in all services that is following the IPC standard and all components are according to IPC standards.

- This PCB supplier is PCBWAY. Since 2003 PCBWAY has become a leading fast PCB manufacturer specializing in both Prototype and Manufacturing, initially producing single-sided circuit boards in the consumer electronics market.

- PCBWAY is ranked among the 4 best board builders in Asia and is best known for its fast turning skills and excellent reliability of timely delivery.

- Today, they have more than 450 employees with modern high-end PCB construction with up to 12 layers. Having a team of professional engineers, as well as a well-established quality system. PCBWay has grown to become the largest manufacturer of PCBs in Asia to work with various customers such as electronics, communications, educational electronics, electrical equipment, Automationsetc.

- Its goal is to be one of the leading PCB manufacturers providing high-quality products and complete customer satisfaction.

Importance of PCB IPC Standard

- To have a high-quality board with good performance, there must be some standards met to get the required results. To get all these aspects in the board there must follow IPC standards.

- All steps involved in the PCB board manufacturing are based on some level of IPC standard.

- There are some benefits we can get after applying the IPC standard in our PCB creation.

High-Quality Products

- To get the high-quality products and board there must be following the IPC standards during the complete process of PCB.

- The creation of such products that offer good results and long time operation will enhance company performance and trust of customers in the company.

- These standards also enhance the operation results of the manufacturer.

Enhance Relation

- The use of the same standards will make mutual collaboration and easy understanding between users and creators.

- Same understanding if workers and engineers can help to easily creates the required products as everyone knows standards that he has to follow.

- The same standard increases the communication level between suppliers, customers, and other people.

Decrease Cost

- Following the IPC standard results in a reduction of the cost of products. enhancement in quality of products and high level of misleading reduction decreases the delay of work. The same standard help manufacturers to expense the same budget for creation.

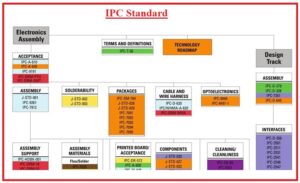

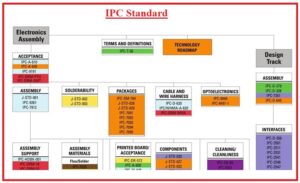

Types of IPC Standard

- IPC-2581 This standard helps to make the transfer of data between PCB design and the creator of PCB. Through this standard design of great accuracy is sent to the manufacturer to make the product.

- IPC-2221 In this standard design of PCB is created and based on different paramerts such s design layout structure, physical features, etc.

- IPC-6012B: This standard set the rule and regulations for the creation of a rigid PCB board. It also set rules of areas such s soldering, and conductor spacing.

- IPC-A-600F It makes the different regulations for PCB board and set different parameters such as copper plating

That is all about the PCB IPC Standard. I have explained all parameters about the IPC standard if you have further query ask in comments. Thanks for reading see you in next post.