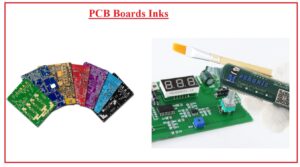

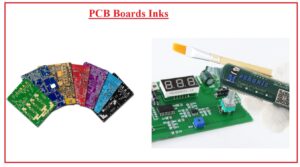

Hello, readers welcome to the new post. Here we will discuss Introduction to PCB Boards Inks. At the PCB board, there is the configuration of different electronic elements is arranged through use of conductive layers, making pads and etching the copper layers on the substrate having non-conductive nature. Different types of PCB are used and manufactured according to requirements such as single layers, double layers, multiple layers, etc.

Hello, readers welcome to the new post. Here we will discuss Introduction to PCB Boards Inks. At the PCB board, there is the configuration of different electronic elements is arranged through use of conductive layers, making pads and etching the copper layers on the substrate having non-conductive nature. Different types of PCB are used and manufactured according to requirements such as single layers, double layers, multiple layers, etc.

Conductive layers are linked through the use of plates through holes named vias. While at advanced PCB board is a very important product of PCBWAY comes with different components such as capacitors, resistances. PCBWay is an example of a China-based PCB (printed circuit board), PCB assembly, SMD Stencil, and Flexible PCB manufacturer. They export to more than 170 countries around the world and process more than 2100 PCB orders per day. I have reviewed other PCBWay companies in the past, but I feel like PCBWay combines excellent value with customer service features in a single service. What’s even more amazing about PCBWay for me, as a manufacturer and customer, is its service. From friendly support staff to their accurate, easy-to-use website features, it all counts in what makes PCBWay a company and the ideal brand for any electronic hobbyist. Here we will discuss different types of inks used in PCB boards and their importance. So let get started.

Introduction to PCB Boards Inks

- PCB boards have layers of conductive material that comprise of different symbolic representations of substances to make projects.

- To make the PCB board different techniques and tools are employed. These manufacturing techniques employed different categories of inks.

- These inks comprise of conductive components such as copper-silver, and gold.

- Ultraviolet inks normally employed in screen printing techniques have curable nature also preferred for printing text and also make schematics on double and multilayers board.

- Different types of PCB board inks are employed which are explained here.

PCB Etching Ink

- The substrate material employed for this category of PCB board is created with copper-clad and has lamination of copper foil.

- It required screen printed through the use of photosensitive etching ink that is treated with exposure and development to trace undisclosed areas, and then blur the ink.

- This category of ink is normally employed to protect the board. After etching the trace ink will be eliminated through use of sodium hydroxide.

- In some boards there is blue color ink is used named circuit blue oil.

- In hardware created with stainless steel created with etching ink. This ink is also named photosensitive ink.

PCB Solder Mask Ink

- This category of PCB ink is named solder resist ink. It is mostly used for PCB boards. The green color layers on the board are solder mask ink.

- Its common categories are photosensitive, developing inks thermosetting ink.

- According to the configuration of boards commonly used inks are PCB hard board solder mask ink, FPC solder mask ink, and aluminum substrate ink.

- Photosensitive solder ink is created through use of UV light. After the application of screen printing, it needed pre baked and then designed.

- Hard boards are used through this solder mask ink. For drying the film photosensitive solder resist ink was also applied for board accurate pads at the soft board.

PCB Silkscreen Ink

- For printing the circuit board this ink helps to make different symbolic representations and characters.

- Mostly used colors for this ink is white and black.

- Mostly used color is white solder mask other than white solder mask created with white ink.

- Silkscreen inks are of thermosetting nature and some have ultraviolet inks.

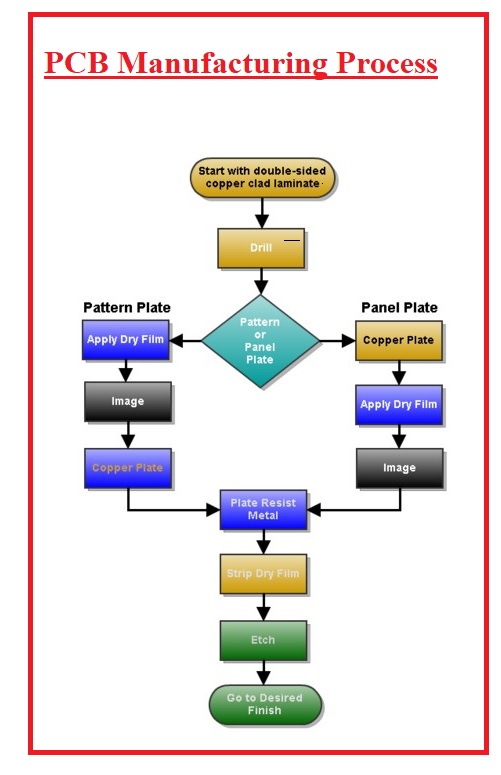

PCB Manufacturing Process

- The steps involved in PCb manufacturing are shown in below figure.

Properties of PCB Ink

- Some features of PCB ink are discussed here

Plasticity

- Refers to the ink by an external force that paralyzes the deformation environment that precedes it. Help improve ink print accuracy

Thixotropic

- Dry gel ink, while viscosity occurs when the material changes to touch, also known as thixotropy, sag resistance

Liquidity

- external ink capacity, extended to four weeks. Fluidity is a combination of viscosity, fluidity, and thixotropy ink in plastic. Large plastic and thixotropic, large mobility; text flow is easily expanded. The movement of small, ordinary, knotted web-occurring Mexicans, also known as textured;

That is all about the PCB Boards Inks. I have explained the different types and importance of inks for the board. Alos explained to you how can get from PCBWAY. Thanks for reading have a good day