In this post we will have a look at History Of Industrial Engineering. The Engineering and Technology Accreditation Board defines industrial engineering as: a field in which mathematical and environmental science knowledge is applied through study, experience, and practical application to build economic, resource, and natural resources. . It uses specialized knowledge and skills in mathematical, physical and social sciences as well as the principles and methods of analysis and engineering to determine, predict and evaluate the results obtained from those systems.

In this post we will have a look at History Of Industrial Engineering. The Engineering and Technology Accreditation Board defines industrial engineering as: a field in which mathematical and environmental science knowledge is applied through study, experience, and practical application to build economic, resource, and natural resources. . It uses specialized knowledge and skills in mathematical, physical and social sciences as well as the principles and methods of analysis and engineering to determine, predict and evaluate the results obtained from those systems.

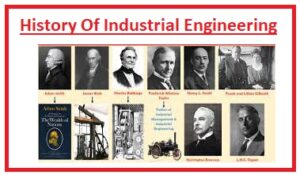

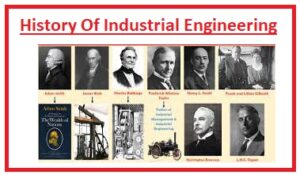

History Of Industrial Engineering

- Fredrick Winslow Taylor is often regarded as the father of industrial engineering, although all his ideas are not original. Thomas Malthus, John Stuart Mill, David Ricardo, and Adam Smith might have also had an effect.All of their work provided free ancient explanations of the successes and limitations of the Industrial Revolution.

- The main contributor in this field is Charles W. Babbage. a professor of mathematics. their main contribution to the field was his book On the Economy of Machinery and Manufacturers in 1832. In this book, he discusses many different topics related to production, a few of which will be very familiar with IE. Babbage discusses the concept of a learning curve, the division of labor and how learning is affected, and the effect of learning on waste disposal.

- Industrial engineering began to take shape around the end of the nineteenth century as a result of a development in this area.

Henry R. Towne emphasized the economic nature of the engineering work. Towne belongs (to ASME) or the American Society of Mechanical Engineers, along with many other pioneers in this new field from the USAThe IE pamphlet states, “ASME was the birthplace of industrial engineering. Towne and Fredrick A. Halsey worked on developing and delivering wage programs to ASME. It was outside these meetings that the Halsey wage system was developed. .This program suggested that some of the benefits be shared with employees. This is the first example of a single benefit-sharing program. - Henry L. Gantt belonged to ASME and presented papers to ASME on topics such as cost, staff selection, training, good incentive programs and job planning. He is the inventor of the Gantt chart, currently the most popular chart used for job planning.

- hat would Industrial Engineering say nothing about Fredrick Winslow Taylor? Perhaps the most well-known industrial engineering pioneer is Taylor.

. His work, like others, included topics such as job planning by management, staff selection, training, and additional compensation for those individuals who could meet the company’s standard set by using his methods. - Gilbreths are accredited for the construction of time and movement lessons. Frank Bunker Gilbreth and his wife Dr. Lillian M. Gilbreth have worked on understanding fatigue, skills development, movement lessons, and time courses. Lillian Gilbreth had a Ph.D. in psychology that has helped her to understand the issues of most people. One of the most important things Gilbrethss has done is to divide the basic human ideas into seventeen types, some effective and some not. They wrote a table of separation therbligs. Functional therbligs help to accomplish the task and therbligs do not work. Gilbreth concluded that the time to complete an active therblig could be reduced but it would be very difficult to eliminate it. On the other hand, inactive therblig should be completely removed if possible.

- In 1948, the American Institute for Industrial Engineers (AIIE), opened for the first time and began to provide technical authenticity to working engineers. Until now industrial engineers had no place in the management of the company. ASME was the only other community that required its members to obtain engineering degrees before the development of AIIE.

What is the future of Industrial Engineers?

- With analytics methods and advanced computer technology, modeling complex production and service plans will be an additional day-to-day task.

- All jobs can be divided into ‘basic work items’. The Gilbreth family found out that there were seventeen of these proposals. The time to complete each movement does not change. Tasks can be learned visually or with the help of a camera for small moving lessons.

- The work environment also needs to be built to promote a good work ethic. Tools should be placed in designated areas to complete the search and selection of therbligs. Workplaces and chairs should be adjusted in high work areas to relieve stress. Whenever possible, gravity suppliers should be used to bring the components to the correct location. Worker’s tools should be designed to eliminate many cuts. Adjustable handles should be designed to maximize operator-user profits.

- Doing a time study. Without quality, the company will find it difficult to estimate the lead time in their products. Very times when the employee does not know what the company expects. To address this issue the IE will create a fairly reasonable expectation for each task.The company’s direct activities are estimated to generate 12% of its total revenue.Another 43% of the cost comes from the actual cost. Another 45% is overused.

- So the idea that you can see the huge profits of production on the ground does not match this light. A good study of time will consider the inevitable delays, fatigue, and to a degree, external disturbances. The duration of the waste steps, such as the search for tools, will not be included in the final level. Expect the workplace to be built to accommodate the work and be free from this type of waste.

- Setting Periods Setup time is the time required to start producing the various components in a machine. If the set times remain large the company will operate with high levels of continuous activity and the finished goods bind companies to valuable cash. Companies that fail to reduce their set times have a tendency to look lazy in relation to their customers.

- Cost IE will generally be responsible for coming up with a cost analysis for equipment procurement. How long the machine is expected to last during the cost analysis?

- Efficiency The traditional way to check efficiency was to keep the machine running 100% The idea was that the cost of the machine could not be distributed beyond the time it was maintained. The higher the efficiency of the equipment, the longer the operation / available time, the better the accounting numbers are considered in relation to the cost of the machine.

- Important IE is concerned with the delivery and flow of goods throughout the plant, often the plant changes as a company.

- Lot Size To allow the manufacturer to remain flexible the size of the production company should be kept to a minimum. This will only be economical after the reduction in equipment use has been achieved.

- Asset Rate Since inventory is a currency that cannot be exchanged until purchased and purchased by a consumer, it should be kept to a minimum. Assets not only save a lot of money but if the customer requests a change then the inventory is at risk of expiration.

- The quality Content level can affect all parts of the system. Low-level items often introduce a repetitive amount of repetition for each process. A common function of IE would be to work with the quality department to set up a Quality Management QMS system.

- Maintenance The amount of maintenance the machine will need varies to be considered. Another issue regarding maintenance is whether existing employees will need to be retrained or not.

Faqs

Major concepts of industrial engineering

The main concepts of industrial engineering are

- Systems thinking:

- Optimization:

- Data-driven decision-making:

Father of industrial engineering

Frederick Winslow Taylor is known as the father of industrial engineering. He gives the idea of enhancing the working efficiency such as time, and motion studies.

First engineering in history

civil engineering is the first engineering in history. Civil engineers make designs and construct of different roads, buildings, and bridges

Industrial engineering in simple words

Industrial engineering uses the study of how to make things good. Industrial engineers use their knowledge of maths, and engineering to increase efficiency and systems outcomes prodcutively

Another name for industrial engineering

industrial engineering also called operations research. Operations research is a field to solve complicated business and industry problems with mathematics and statistics to solve complicated problems in business and industry.

5 things industrial engineers do

- Design and improve manufacturing processes

- Develop and implement quality control systems

- Optimize supply chains

- Manage projects

- Improve workplace safety and ergonomics

What is the father of all engineering?

There is no single father of all engineering. Some famous engineers are

- Archimedes (287-212 BC):

- Hero of Alexandria (10-70 AD):

- Leonardo da Vinci (1452-1519):

What is the highest-paid engineer?

a petroleum engineer is considered the highest-paid engineer. They can earn an average salary of $137,520 per year.

What engineering is closest to industrial?

systems engineering is like industrial engineering. Systems engineers make design and make the complicated operation of different systems such as aircraft, spacecraft, and manufacturing systems.