Hello readers welcome to new post. Here we will discuss Tips to reduce PCB Manufacturing Cost. PCB printed circuit board that used for creation of different projects. PCB has become the vital part of any electronic device and projects. PCB has conductive layers of copper that has symbolic representation of different components that are connect on the board for projects creation.

Hello readers welcome to new post. Here we will discuss Tips to reduce PCB Manufacturing Cost. PCB printed circuit board that used for creation of different projects. PCB has become the vital part of any electronic device and projects. PCB has conductive layers of copper that has symbolic representation of different components that are connect on the board for projects creation.

There are different PCB components are needed for creation of this board that needed certain prices and cost. So there is need of certain experts techniques and applications to make the PCB in good quality and within reasonable cost. Here we will learn how PCBWAY created PCB in reasonable prices and quality and demands that users needed. So let get started

Tips to reduce PCB Manufacturing Cost

- The manufacturing and designing of PCB required professional engineers and accurate machines.

- When you are new to this fields and have no experience for design and creation of PCB boards than can cause to make expensive and not goof board according to requirements.

- So for this you must need serious demands and qualities for creation of boards with that if you are new to this fields you must contact the PCBWAY.

- PCBWAY is one of the best PCB supplier that offer the PCB services with great quality and prices.

- The basic function of PCB fabric is to make PCB prototypes. They have developed a simple and effective PCB quote form, which extends to choose lot of parameters depending on your design.

- Through PCBWAY you can get ten pieces of 2 layers with dimensions of 50 by 100 millimeter in just five dollars without shipping cost. WIth manufacturing time of just twenty four hours.

- Different features such as boards dimensions, silkscreen color surface finishing cooper thickness and technique of penalization can be availed by PCBWAY.

- So all PCB related services can be avail from this PCB supplier with affordable prices and good quality.

- So there are some points that you must have to reduce the PCB manufacturing and make in less time.

Accurate Traces of Board

- For making connection among the different PCB parts there are traces created. It is wire that used to make connection

- The width of trace normally is 0.005 inches but for good results of the PCB manufacturing traces dimension are kept about 0.008 inches.

- In case cases there is need of o.005 inches traces width that considered as costly process.

- to avoid the short circuits between coppers traces there is width of 0.005 inches is preferred.

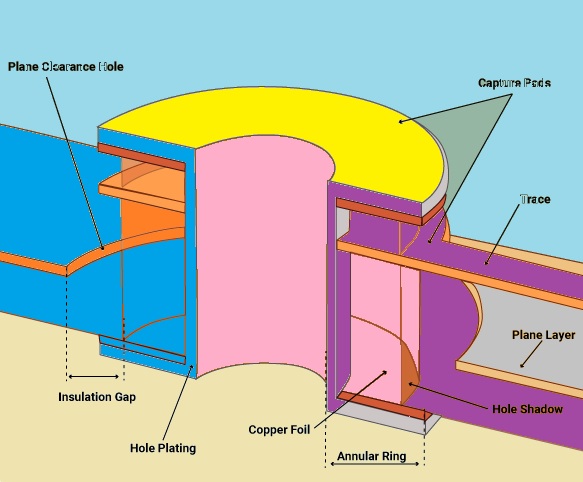

Accurate connection between Pads and Holes

- There must be good connection between Pad and holes of boards to make the accurate design configuration.

- The main benefit of pad is to make sure the copper lies in the holes has fine link with the pad traces.

- The size of pad must be 0.015 inches larger than the hole size.

- For example if there is hole size is 0.010 then the pad must be 0.025 inches.

Importance of Hole Dimensions

- For accuracy of PCB board design there must be connection between hole size and configuration of connection between holes and traces is very important.

- The feature to make small size holes for pcb boards is very common in use from last some years.

- Now hole size is o.010 inches is commonly used and for high quality it can be 0.020 can be used.

Enough Space between PCB Edge and Copper

- There is another fact that plays important role to make board in good way is there must be some certain spaces between copper and edge of board.

- There must be copper used on board and edge of board should be 0.010 inches.

- The distance less than cause the serious problems for board creation.

Solder mask Quality

- There must be high quality solder mask used to cover the pads of boards. If solder mask is not good can cause faults in design of boards increases the cost and time for design.

- With the use of solder mask there must be high quality silkscreen.

That all about reduce PCB Manufacturing Cost. I have explained all details about this process with the details if you have any further query ask in comments. with that if you are new to this filed must contact with the very experienced and most trustable PCB supplier PCBWAY. That will help you to make board with less cost and high quality.