Hello readers welcome to new post. Here we will discuss Introduction of Solder Mask and Applications. Solder mask is liquid like layers created with the polymer and placed on the traces created with copper at the circuit boards. This layers helps to save the board from the oxidation and save the solder bridges to creates. The electrical connection between two conductors created through un-intentionally is called solder bridge.

Hello readers welcome to new post. Here we will discuss Introduction of Solder Mask and Applications. Solder mask is liquid like layers created with the polymer and placed on the traces created with copper at the circuit boards. This layers helps to save the board from the oxidation and save the solder bridges to creates. The electrical connection between two conductors created through un-intentionally is called solder bridge.

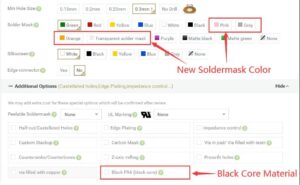

With the use of handed features there is reflow techniques used for application of reflow and wave soldering. The basic colors of solder mask is green but different colors can also avail. For this purpose you must contact to the PCBWAY that are offering the different colors solder mask boards according to their users and customers needs. Here we will covers details about the solder mask and will learn different types of board. So let get started.

Introduction of Solder Mask

- During the designing configuration of PCB board solder mask is noted as layer of PCB board and defined like the gerber file similar to other files as copper and silkscreen.

- It also called the solder stop mask and solder resist that is thin lacquer similar to polymer layer helps to save the board from different conditions.

- The location where solder mask is not applied called solder mask opening.

- PCBWAY comes with features to get the least distance among the IC pins is 0.2 millimeter and distance is less then 0.2 millimeter then they offered the solder mask opening.

- PCBWay is a professional quick turn PCB prototyping,PCB Assembly and low-volume production manufacturer located in Shenzhen China.(3 major PCBs and 2 PCB Assembly production).

- Their “Advanced” offering and this shows the very best that PCBWay can offer:Full Spec PCBs, Highly Specialized Precision PCBs, & Large Scale Production, but sometimes some plates and materials are temporarily out of stock.

How to get Solder Mask

- There are different PCB providers are working in the world but one of the best PCB supplier is PCBWAY that are offering the PCB based services to allover the world with that also offered the solder mask features to their users.

- On September 13, 2021 offered the different colors combination for solder mask that are pink gray orange and transparent. Before this addition they also offering the matte black, matte green and purple to fulfill the needs of users now they are offering the gray pink and orange colors masks.

- PCBWAY offering this features to the Advanced PCB not for standard PCB boards features.

- PCBWAY also offering the new black core PCB material that is black FR-4 and will get extra charges.

- Further details offered by the PCBWAY for solder mask can seen here

Difference between Non-Solder Mask Defined and Solder Mask Defined Patterns

- Mostly PCB boards are named as non solder mask or NSMD. Generally non solder mask nominated pads comes with solder mask opening greater then the copper pads.

- NSMD pattern gives the larger soldering surface area and good clearance among the pads.

- While SMD pattern comes with solder mask opening small size then the copper pads.

- This technique is normally used when the element has narrowed pitch. As solder mask opening is small it decreases the surface area of the pads to reduce the solder smudge over the pad.

Types of Solder MASK

- There are main four types of Solder mask that are described here.

Epoxy Liquid

- Epoxy liquid is considered as less expensive board. Epoxy is thermosetting polymer which used in different applications.

- Silkcreening is printing method which applied woven mesh to fulfill the ink blocking stencils.

- Mesh make the opening area for moving of ink. Silk is mostly used in art then the synthetic fibers are used in electronic applications.

Liquid Ink Photoimageable

- It named as formulation of ink. Ink placed in the board either spray form and silkscreen after that exposed to the pattern creation.

- HASL is used for application of this process. For this process there is need of clean environment.

- When the UV is applied the mask is eliminated through application high pressure water spray.

Dry Film Photoimageable

- It is applied through use of vacuum lamination after that showed and developed. Then opening are made in the pattern and portions can be made on the copper pads.

- Copper is made on the board in the holes and on the tracing part. Tin is used for saving the copper circuits.

Top and Bottom Side Masks

- At top solder mask permits the electronic engineer to get the opening the green solder mask layers created on the board through other three techniques.

- Elements pinouts after that connected on the board through using the defined positions.

- The design of conductive layers at upper side called top and at lower side called bottom solder mask side.

Applications of Solder Mask

- Currently PCB solder mask is used for creation of PCB board and mass assembly. Solder mask provides the protection to the copper layers.

- Therefore solder bath permits the tinning fo every copper pad at the board.

That is all about the Solder mask i have explained all details about the solder mask. If you have further details ask in comments. See you in next post. For getting the best service of Solder mask must contact the PCBWAY