Hello, readers welcome to new post. Here we will discuss Introduction to Wetting Balance Test. This test of PCB board is considered a solderability test that examines the wetting pressure in the molted solder and surface with the passage of time. In PCB boards these tests helps to measure the solder operating speed for lead-based and no-lead parts of mounted and through techniques. It is done through the use of lead and non-lead soldering processes.

Hello, readers welcome to new post. Here we will discuss Introduction to Wetting Balance Test. This test of PCB board is considered a solderability test that examines the wetting pressure in the molted solder and surface with the passage of time. In PCB boards these tests helps to measure the solder operating speed for lead-based and no-lead parts of mounted and through techniques. It is done through the use of lead and non-lead soldering processes.

During the performance of the wetting balance test here is one test also performed called the solder wetting test. Through this test solderability of board surface can be done either soldering can be done easily or not. There are different PCB suppliers that offer different PCB based products and PCB ability and accuracy measuring testing services. PCBWAY is one of them and offers PCB-based services in best prices and quality. For more than ten years in the field of PCB prototype and manufacturing, they are committed to meeting the needs of our customers from a variety of industries in terms of quality, delivery, cost-effectiveness and any other complex applications. As one of the most experienced PCB manufacturers in China, they pride themselves on being the best business partners and good friends in all aspects of your PCB needs.

Like the PCB business, their PCBA resources also specialize in prototyping and small-volume production, making PCBWay a single point for the construction and assembly of boards. This program makes your R&D easier and more time-saving. To fulfill hundreds of daily orders from around the world, we have established ourselves as the leading suppliers of PCB and PCBA services with our consistent quality and excellent services.

Introduction to Wetting Balance Test

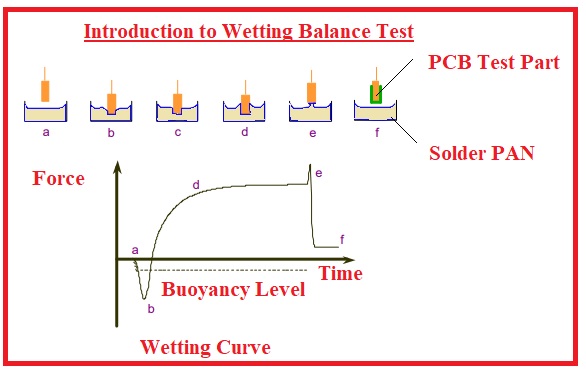

- The wetting balance test is performed on the PCB board to find the wetting forces of attraction among the PCB board surface and molted solder.

- This test determines the time taken by the solder through which it wet the pad of components connected on the board.

- When this test is performed PCB board is placed and removed through the modern solder with speed of one to five millimeters per second.

- PCB placement and removal in the molted solder at ninety degrees of angle.

- Two forces commonly known in fluids are work on the board are surface tension and buoyancy.

- The net of these forces is measured through use of LVDT and the measured value is drawn in shape of a graph that indicates the net force and with time interval. Through that quantity of wetting measured.

Basics of Wetting Balance Test

- The main purpose of this test is to finds the value of pressure between the molted solder and PCB with the passage of time. This test helps to find the time duration for solder to become the wet elements connected on the board.

- During this test, PCB is placed and comes out in the hot solder pan fastly. During in and out PCB pan keep stable for six to ten seconds. Surface tension and buoyancy forces are work.

- That is work as refusing pressure over the wetting pressure. The direction of reflection force is upward and soaking loads work downward.

- Before the working of wetting pressure PCB board move with high speed in PAN. Rejecting pressure is larger which causes the graph to move minus axis. After that wetting pressure dominates the rejecting pressure.

- When both pressures are the same then meet at the zero axis that called time to zero

- The wetting balance test is a fast and reliable way to know about the PCB board completion process.

Importance of Wetting Balance test

- The wetting balance test is considered a compulsory test for findings the strength of the elements connected on the board.

- That is helpful to find the strength of soldering operation in fine way. Wetting features of PCB through use of fluid solder is a significant characteristic of the soldering process. The wetting balance test is considered as the finest option to determine the wettability of lead and surface-mounted board.

Precautions for Wetting Balance Test

- This test is performed with certain precautions such as flux and bath temperatures considered as normal procedures. That is helpful to find the solderability of boad through the soldering technique.

- This test is done at solder bath temperatures of ten to fifteen centigrade. PCBWAY performed all test with high levels experts and precautions needed for PCB and provides high-quality results to customers.

Types of Wetting Balance Test

- There are different types of wetting balance tests are discussed here

Surface mount simulation test

- SMT components are tested through use of surface-mounted simulation techniques and no normal process like PCB testing used such as dip and observation.

- The ceramic sheet is printed through the use of a certain solder paste. After that, it dip in the paste, and the reflow process done in normal way.

Dip and Observe

- This test is very commonly used. This test worked under the lead for almost 8 hours of steam process which increases the again process.

- The board is then placed in the solders through use of triggered rosin flux by experts like the PCBWAY have.

- Then they clear that are according to requirements. Physical observance and clear view techniques are used to know about the accuracy of the test and fine completion.

That is all about the Wetting Balance Test all details has been explained. If you have any further query ask in the comments TO get all types of PCB-based test must contact the best PCB supplier that is PCBWAY.