Hi reader I hope you all are having fun in your life. In this post, we will have a detailed look at an introduction to Rotameter. A Rotameter is an expedient which processes the volumetric flow rate of liquid in a padlocked duct. It is a type of meter known as variable area meters, which calculate the rate of liquid flow by changing the cross-sectional area when the liquid passes through that area, producing a quantifiable consequence.

Hi reader I hope you all are having fun in your life. In this post, we will have a detailed look at an introduction to Rotameter. A Rotameter is an expedient which processes the volumetric flow rate of liquid in a padlocked duct. It is a type of meter known as variable area meters, which calculate the rate of liquid flow by changing the cross-sectional area when the liquid passes through that area, producing a quantifiable consequence.

The first adjustable area meter with revolving float was created by Karl Kueppers in Aachen in 1908. This is labeled in the German patent 215225. Felix Meyer originated the company “Deutsche Rotawerke GmbH” in Aachen knowing the vital position of this creation. They enhanced this invention with new outlines of the float and of the cut-glass tube. Kueppers developed the special contour for the privilege of the glass tube that understood a regular flow gauge. In this article, I will explain in detail its working, principle, equation, etc. So let’s started with the introduction to the Rotameter.

Introduction to Rotameter

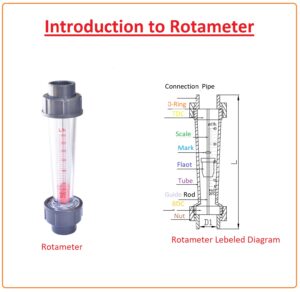

- Rota meters an expedient that processes the volumetric flow rate of liquid in a padlocked duct. It is a type of meter known as variable area meters, which calculate the rate of liquid flow by changing in the cross-sectional area when the liquid passes through that area, producing a quantifiable consequence.

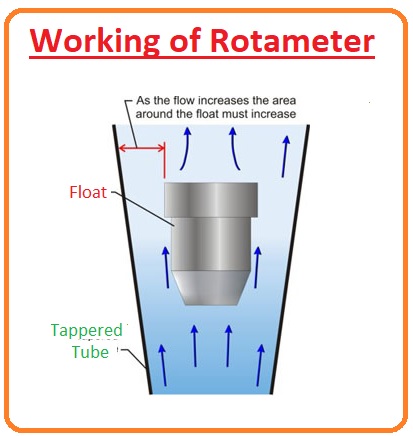

- A rotameter comprises of a tapering tube, characteristically prepared of glass with a ‘float’ (a molded weight, prepared either of anodized aluminum or an earthenware), intimate that is strapped up by the drag force of the movement and dragged down by gravity.

- An advanced volumetric flow rate through a given area upsurges flow swiftness and drag force, so the float will be strapped up. Though, as the inside of the rotameter is funnel formed (widens), the area about the float through which the middle flows upsurges, the flow speed and drag force drop till there is mechanical equilibrium with the float’s weight.

- Floats are prepared in numerous altered forms, with spheres and ellipsoids being the most communal. The float can be slantwise fluted and partly painted so that it alternates axially as the liquid passes. This displays if the float is wedged subsequently it will only swap if it is free. Interpretations are frequently taken at the upper of the broadest part of the float, the midpoint for an ellipsoid, or the topmost for a tube. Some builders use a changed standard.

- The “float” must not float the fluid: it has to have a greater density than the fluid, else it will float to the topmost even if there is no flow.

- The automatic nature of the gauging principle delivers a flow measurement that does not need any electrical power. If the tube is made of metal, the float location is transported to an exterior pointer via a magnetic connection. This competence has significantly prolonged the variety of submissions for the adjustable area flowmeter since the measurement can be detected tenuously from the procedure or used for automatic control.

Construction of Rotameter

- There are two main parts it has first one is a Graduated tapering metering cut-glass tube and the second is Float. Let’s discuss them one by one.

Tapered tube:

- Safety protected glass tube is in universal use for gaging both fluids and gases. Metal tubes are used wherever dense fluids are used or temperature or pressure condition is pretty high. Plastic tubes are also used in certain rotameter enterprises due to their lesser price and extraordinary influence power.

Float:

- Floats can be made of metals of numerous thicknesses from lead to aluminum or from glass or plastic. Stainless steel floats are communal ones. Float figures and sizes are also various for altered submissions. For minor movements floats are sphere-shaped. In the given diagram, you can see different types of floats.

Let’s see a diagram of floats.

Now we discuss how it works, we will also study its working principle.

Working of Rotameter

Working principle:

- It is a moveable area meter that works on the principle of upthrust force applied by liquid and force of gravity.

- The liquid reaches the tapered tube, some of the liquid collides amenably with the float. Some part of the liquid passages from boundaries.

- There are two forces are performing in this case first one is upward force (Buoyancy) and the second one is the Weight of the float.

- Annular space upsurges due to the rising in area of the tube. When symmetry is proven the float comes to rest condition.

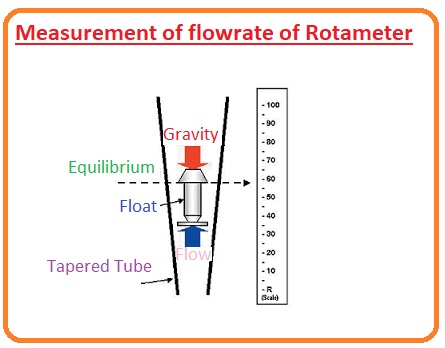

Measurement of flowrate:

- The flow rate is sedated openly from standardized gage. The interpretation is celebrated usually from finish point of top of the float.

Features

- These are the main features and properties of Rotameter. Let’s study them.

- Its accuracy is up to ± four percent

- It is available in quadrangular or tapering shape.

- There is an etched pattern of assortment on the body of this device.

- Its flow capability is seven GPH to twenty GPM in the case of liquid and 2.6 SCFH to sixty SCFM for gases.

- It can bear supreme pressure for liquid is one twenty-five psig and hundred psig for gases.

- Its extreme temperature conditions for liquids is 130°F (54°C) and for gases is 100°F (38°C).

- Its ambient temperature is up to thirty-three to 125°F (one to 52°C).

Advantage of Rotameter

There are numerous advantages of a rotameter over a more complex flow meter comprising:

- Rotameters can be fitted in zones with no power meanwhile they only need the possessions of the liquid and gravity to the measurement of liquid flow, so you do not have to be worried about confirming that the tool is detonation resistant when connected in areas with incendiary liquids or gases.

- Rotameters can be connected with customary pipe accessories to present piping or over aboard. You do not have to concern about conventional runs of the pipe as with a magnetic or turbine flow meter.

- Rotameters are modest expedients that are mass-created out of cheap ingredients possession speculation costs low.

- A look at a Rotameter turns as a vision glass telling the worker that a filter wants washing, that there is certain other delinquent producing staining of the water, or that the liquid is essentially moving. With a translucent rotameter, they can promptly see if there is any build up on the float or tube parapets.

- With a correctly preserved rotameter, the machinist can imagine continued high repeatability.

- Rotameters compromise wide flow dimension ranges or range aptitude. A characteristic ratio of 10:1 from supreme to least flow rate can be probable. Workers will be able to calculate minimum flow rates as low as 1/10 of the rotameter’s extreme flow rate deprived of damaging the repeatability.

- The rotameter’s gauge is lined since the measurement of flow rate is founded on area difference. This income that the flow rate can be recited with the same degree of correctness through the complete range.

- Pressure damage due to the rotameter is negligible and comparatively continuous since the area through the tapered tube upsurges with the flow rate. These consequences in abridged driving costs.

Disadvantage of Rotameter

There are also some disadvantages to the usage of rotameters that you must keep in mind:

- Since gravity plays a key part in the flow dimensions the rotameter must constantly be fitted perpendicularly with the fluid moving up through it.

- The proceeded gage on the walls of the rotameter will only be legal for the definite liquid and circumstances where it was adjusted. The exact gravity of the fluid is the main stuff to deliberate, though the fluid’s viscidness and any temperature variations might also be important.

- Rotameter floats are usually intended to be unresponsive to viscosity, but the worker should confirm that any rotameters connected in their scheme are standardized to their precise arrangement preceding to trusting on the flow dimensions delivered.

- It is problematic for rotameters to be modified for mechanism interpretation, though a magnetic float can be used in some illustrations.

- Rotameters are characteristically made of translucent substantial, though all workers should check the chemical compatibility of the meter with their liquid preceding to full connection.

Read also:

- What Does an Anemometer Measure, Types & Work Process

- Introduction to Magnetic flow meter, Working, Types & Applications

- Ultrasonic Flow Meter

Faqs

- The rotameter is a flow meter device that measures the volumetric flow rate of gas or fluid. It comes with a tapered tube with a moving inner float. it is also called a mechanical flow meter, gravity flowmeter

- The variable area flow meter is a flowmeter that measures the volumetric flow of liquids and gases. There is no difference in the variable area flow mete, rotameters, or flow meters, and can be interchangeable.

- The rotameter is device that measures the volumetric flow rate of fluid in a closed tube. It is part of a meter called variable area flowmeters, that measures flow rate by allowing cross-sectional area fluid to move through to change and cause measurable effects.

- The area of proportional to the volume flowing in units of time through variable meters, so these meters are increments of equal scale. The linearity of a rotameter scale is about 5%.

- Each rotameter comes with two main components, a tapered metering tube created with glass, metal, or plastic and a float that configured in a tube

- The common use of rotameter flow meter is to measures flowrate of liquids and gases. It comes with plastic metal or glass tube and float. Float reponses to flowrare variaion is linear and 10 to1 flow range.

- Output of flow detecion component is linear. The pressure loss is less. Glass tube rotatmeter is simple and less cost.

- it an easy use as long as flow is defined in field, and its disadvantage is that chances of fragile glass tube, specailly unguided structure rotors for gases.

Guys, I tried my best to write the simplest article for you so you can easily understand it. I shared my best knowledge to you, if you want further information about it please ask in the comments. I will solve your problems. Goodbye till the next article I will share it soon.