Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at ultrasonic Flow Meter. There are numerous types of methods and instruments are used to calculate the fluid velocity. An ultrasonic is such an instrument that uses ultrasonic waves to compute the velocity of liquid to find the volume in m3 of fluid flow. This meter finds the average velocity alongside the direction of a discharged ray of ultrasound, by averaging the alteration in calculated passage time among the pulsations of ultrasound spreading into and in contrast to the direction of the flow.

Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, we will have a look at ultrasonic Flow Meter. There are numerous types of methods and instruments are used to calculate the fluid velocity. An ultrasonic is such an instrument that uses ultrasonic waves to compute the velocity of liquid to find the volume in m3 of fluid flow. This meter finds the average velocity alongside the direction of a discharged ray of ultrasound, by averaging the alteration in calculated passage time among the pulsations of ultrasound spreading into and in contrast to the direction of the flow.

An ultrasonic flow meter is disturbed by the audible behavior of the liquid and can be obstructed with viscosity, density temperature, and suspended particulates. These flow meters are available at different prices but not cost too much due to the absence of the moveable portion. In today’s post, we will have a detailed look at its working, applications, advantages disadvantages, and some other related parameters. So let’s get started with ultrasonic flow meter.

Ultrasonic Flow Meter

- Ultrasonic flow meter uses ultrasonic waves to calculate the speed of the moving liquid in any tube or pipe.

- This meter uses the phenomena of Doppler Effect for determination of the velocity of the liquid, Doppler Effect explains the variation in the frequency of waves with respect to the observer and source.

- When ultrasonic flow meter is used in such fluid that is not moving then the waves send by the meter and transmitted waves have the same frequency.

- But when the meter is used in moving fluid then the frequency of a reflected wave is different from the sending wave according to the Doppler Effect.

- With the increment in the speed of liquid, the variation in the frequency also increases. The transmitter work on the signal received from the transmitted wave and reflected wave to find the rate of flow of fluid.

- Transit time ultrasonic meter transmit and get waves among the ultrasonic transducers in up-stream and down-stream direction in a pipe.

- But when the fluid is in static condition then this meter consumes the same time to move up-stream and down-stream among the sound transducers.

- When the liquid is moving then the portion of fluid moving in an upward direction will take larger time then the portion moving downward.

- With the increment of liquid speed the alteration (difference) among the upward moving liquid and downward moving fluid increases.

- The transmitter of the meter find the time of upward-moving fluid and downward moving fluid to find the rate of flow of liquid.

- The use of this meter provides highly precise results so it mostly preferred to measure the flow of the costly fluids such as petroleum and natural gas.

- With the different features, it also has some drawbacks such as its price is higher, creates some problems when the diameter of the liquid pipe vary and it decreases its accuracy.

- The quality of this meter is that acidic, abrasive and dense fluid can passes through this module. In some meter wave sending and receiving portion is mounted on the exterior of the fluid pipe so it remains dry during its processing.

- Momentary flow calculations can be done using handheld meters with clamp-on measuring devices (transducers). These transducers are particularly beneficial when fluid tube or pipe is not separate from the system like nuclear industries.

- Further, clamp-on meters can also be employed to find the flow without respect to constituents of assembly, erosion, and corrosion problems.

Working of Ultrasonic Flowmeter

- The working of this meter depends on the Doppler Effect that fined the frequency variation of the transmitted and reflected wave.

- In ultrasonic flow, meter sound is transmitted and when reflecting back after colliding with the fluid then variation in the sound wave frequency tells about the fluid velocity.

- An ultrasonic wave is sent in the liquid pipe variation in the frequency of waves is equal to the flow rate of a liquid.

- The requirement for the fluid is that it must have one hundred parts per million of one hundred microns or higher suspended constituents.

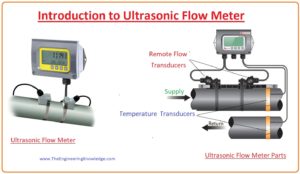

- Normally any ultrasonic flow meter comprises a transmitter (indicator, totalizer) and transducer.

- The operator of the meter chooses the arrangements of the meter according to liquid type, and diameter and concentration of particles in the fluid.

- The transmitter’s signal extreme point typically modifies to filter mechanical and electric noise.

- The operation of the transducer depends on the frequency generator in the transmitter that is mounted on the external side of a fluid pipe in a clamp-on design configuration.

- The transducer produces an ultrasonic signal that crosses the wall of the pipe and entered into the fluid after that reflect back signal and the transmitted signal difference is converted into the electronic signal by the transmitter.

- An ultrasonic flow meter that is mounted on the external side of the fluid pipe work fluently without any moving portion.

- Such external configuration create less pressure loss, less disturbance for fluid and require less repairing.

- If correctly adjusted, they can have ± one percent accuracy, though, the pipe wall and air among the wall and the fluid can produce signal disturbance.

- Furthermore, a stainless steel pipe wall can process the transmitted signal to the level that the echoed signal will look to experience the main frequency change.

- The transit time ultrasonic flow meter calculates the time variation in time taken by the signal to reach from transmitter to receiver point.

- If the fluid is in a static position then the time taken by the signal will be similar in both directions.

- If the fluid is moving then the speed of the sound wave will be larger in one direction and will be less in the opposite direction.

- There are some flow meters that use cross association among the up direction fluid stream and down direction fluid stream transducer sets to calculate flow.

- Some meters of this configuration use processors to shift spontaneously among clean and muddy (dirty) correlation factors.

How to select the Right Magnetic flow Meter?

- Such flow calculations where less pressure loss is required ultrasonic flow meter is preferred and its repairing cost and installation are also less.

- It also used to find the flow of liquids that has wastage or different high-density particles.

- It also a best meter for such liquids that have less or no wastage particles like water and oil.

How to Install an Ultrasonic Flow Meter

- Both types of ultrasonic meters that are Doppler ad transit time meter are installed on the external side of the fluid pipe.

- The benefit of this arrangement is that pressure loss decreases that is a general issue in the case of meters that are installed in the fluid flow line.

- THE proper operation of the meter depends on the suitable installation of meter for flow measurements.

- As variation in temperature of pipe and serious vibrations can disturb the position of the meter.

- In some certain installation where hard materials such as plastic, concrete, are exits ultrasonic flow meter do not operate properly.

- Before the uses of meter, you must observe these parameters.

- Further to get high accuracy flow rate results, the pipe must completely be filled with the fluid.

Advantages of Clamp-On Ultrasonic Flowmeters

- These are some advantages of the clamp-on ultrasonic flowmeter.

- It provides nondisturbance measurements of flow.

- It can be used for the fluid calculation of nonconductive liquids.

- It can be easily mounted in any fluid pipe without any disturbance in the movement of flow.

- It can be installed in a pipe’s diameter of 12.7 to 7600 millimeters.

- It operation temperature is from minus forty Celsius to two hundred degree Celsius.

Comparison of Ultrasonic vs Other Types of Meter

| Meter Type | Advantages |

| Coriolis | This meter can be used to find the flow of medium and large diameter pipes. |

| vortex | It is less invasive and has less flow ability. |

| Magnetic flow meter | It can be used to find the flow rate of gases steam and nonconductive fluids. |

| DP | In this meter, less pressure loss is need during recalibration. |

| turbine | In this module, there is no moving part and it is less invasive. |

Ultrasonic Flowmeter Features

- These are some features of the ultrasonic flow meter.

| Flow range | Its flow range is 0.01-20meter per second in both directions. |

| accuracy | Plus-minus 0.3 to five percent. |

| Repeatability | Normally 0.5 percent plus-minus. |

| Pipe Size | 12.7 to 7600 millimeters. |

| Operating temperature | |

| transducer | –40 Celsius to plus two hundred Celsius. |

| transmitter | –10 to fifty centigrade |

| Datalogging | Its value is normally larger than the 100000 data points. |

| output | Four to 20 milli ampere pulse (signal) |

| Power | It has a built-in battery have 12 volts input supply its operation time is eight to 36 hours. |

| Dimensions | 250 x 150 x 40millimeter |

| weight | One to two kilograms. |

Ultrasonic Flowmeter Installation Requirements

- For the required accuracy, these conditions must keep in mind before installation.

| Requirements | |

| Location | Larger than ten diameters for straight length pipework must exit at the upward-moving stream of fluid and five diameters for down moving fluid stream. |

| Wall thickness | For good accuracy, pipe thickness should be calculation able. Some meter has thickness gauge meter. |

| Liquid medium | Before installation, it must know the category of fluid and bubble ration in fluid should not be greater than five percent. |

| Pipe conditions | At the external wall of the fluid pipe, there should be no dust, paint and some other related material exits. |

Application Cautions for Ultrasonic Flowmeters

- These are some applications ultrasonic flowmeter that is described with the detailed.

- For transit time ultrasonic flowmeters, be certain that the liquid can sufficiently manner ultrasonic waves since the flowmeter will not calculate when the ultrasonic waves cannot enter the flowing creek amid the transducers.

- Similarly, ultrasonic waves should be able to enter the fluid for Doppler flowmeters to work precisely. When the liquid is rather dense and does not penetrate the liquid, Doppler flowmeters tend to measure the speed of the liquid at or near the pipe wall, which can cause important measurement fault or effect the flowmeter to flop.

- For Doppler ultrasonic flowmeters, be certain that the liquid sufficiently imitates ultrasonic waves, because the flowmeter will not work without an echoed ultrasonic signal. Dependent upon the enterprise, echoes can arise due to slight fizzes of gas in the flowing creek or the existence of vortexes in the flow stream.

- If not previously existing in the flowing stream, producing these bases of echo can be hard in rehearsal. Luckily, some mixture of fizzes of gas or whirlpools is existing in most submissions.

- The speed of the dense elements in the slurry can be dissimilar than its liquid mover fluid. Be cautious smearing ultrasonic technology when the solid particles can become concentrated in one part of the flowing stream, such as in a flat pipe flowing at a moderately little speed.

- Be cautious when smearing Doppler ultrasonic flowmeters in slurry submissions since the dense elements can harvest durable signals that can affect the Doppler flowmeter to measure the speed of the objects and not the speed of the watery.

- Evade liquids that can pelt moistened transducers or fleece the pipe partition in front of non-moistened transducers since the flowmeter will not work when the ultrasonic waves cannot arrive the flow watercourse. Be certain to uphold dependable clamp-on transducer networks to the pipe partition since the flowmeter will not measure when the ultrasonic waves are not capable to influence the liquid.

- Be assured to recognize the procedure and smear these flowmeters correctly. For example, an episodic housework method upstream can cause the flowmeter to halt waged since the dust may not permit ultrasonic energy to license through the liquid. Additional, if the filth pelts moistened transducers, the flow meter may fail to work till it is gutted.

So friends this the detailed tutorial on the ultrasonic flow meter I have mentioned each and every parameter related to this meter in this post. If you still have any queries about this module ask in comments. I will resolve your queries regarding this meter. Thanks for reading. See you in the next tutorial.

You have written a very good article, I have fully understood, you have cleared all the doubts, thank you very much for this article.