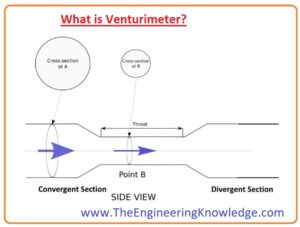

A venturi meter is an instrument which is to calculate the liquid flow in tubes. This meter is works on the principle of Bernoulli’s equation. Inner side of the pipe, pressure variance is produced by dealing the cross-sectional area of the movement passageway. This alteration in pressure is calculated with the assistance of a manometer (pressure measuring device) and supports in the decisive rate of liquid movement or extra ejection from the tube route.

A venturi meter is an instrument which is to calculate the liquid flow in tubes. This meter is works on the principle of Bernoulli’s equation. Inner side of the pipe, pressure variance is produced by dealing the cross-sectional area of the movement passageway. This alteration in pressure is calculated with the assistance of a manometer (pressure measuring device) and supports in the decisive rate of liquid movement or extra ejection from the tube route.

By way of the chief inlet, zone is further as associated to throat, speed of liquid at throat upsurges so pressure cuts. Through this, a pressure change is produced amid the inlet and the gorge of the venturi meter. Henceforth, by dipping the cross-sectional area of the movement way, a pressure change is produced and we calculate that change in pressure by Bernoulli calculation and ejection formula.

Introduction to venture flow meter

- A venturimeter is an instrument which is to calculate the liquid flow in tubes. This meter is works on the principle of Bernoulli’s equation.

- Venturi tubes are obtainable in dimensions up to 72 inches and can permit 25 to 50 percent additional flow than an orifice plate with a similar pressure droplet.

- The original price of a venturi meter is higher, so these are mainly used on greater movements or on much problematic or difficult flow submissions.

- These meters are impervious to speed outline belongings and so need fewer conventional tubes over an orifice meter. Their contoured natural surroundings, joint with the self- scrubbing act of the movement over the pipe, mark the expedient protected to erosion, corrosion, and interior gage shape up.

- In viciousness of its great original price, the entire price of possession can be promising as investments in fitting and working and preservation prices.

- The traditional Herschel venturi meter has an extended movement component categorized by a tapering inlet point and a deviating outlet point.

- Inlet pressure is gage at the entry point and stationary pressure in the throat unit. The pressure blows forage into a communal annular compartment, given that a normal pressure interpretation above the complete perimeter of the component. The traditional venturi is imperfect in its submission to fresh, non-eroding fluids and airs.

- You in see in the given diagram that in the small form venturi, the entry angle is augmented and the annular compartments are swapped by tube blows. The small-form venturi upholds numerous of the recompenses of the traditional venturi, but at an abridged original price, smaller length and compact weight.

- Pressure blows are situated 1/4 to 1/2 tube diameter up the watercourse of the inlet funnel and in the mid of the throat unit.

- Piezometer jewels can be used with big venturi pipes to recompense for speed outline misrepresentations. In slurry package, the tube blows can be eliminated or substituted with chemical closures, which can remove all dead-ended hollows.

- There are numerous exclusive movement venturi pipe projects which deliver even improved pressure retrieval than the traditional venturi. The finest recognized of these trademarked projects is the general venturi. The numerous movement pipe enterprises differ in their outlines, blow positions, created d/p and in their unimproved head damage. They all have small place distances, characteristically variable amid 2 and 4 tube diameters.

- These exclusive movement pipes typically price fewer than the traditional and small-form ventures as their small lay length. Though, they might also need more square tube tracks to state their movement speed outlines.

- Movement venturi pipe enactment is greatly posh by standardization. The imprecision of the liberation constant in a worldwide venturi, at Reynolds statistics beyond 75,000, is 0.5 percent.

- The imprecision of a traditional venturi at Re > 200,000 is amid 0.7 and 1.5 percent. Movement pipes are frequently provided with liberation constant charts since the discharge constant vagaries as the Reynolds numeral drips.

- The dissimilarity in the release constant of a venturi consequence produced by tube unevenness is less than 1 percent since there is unceasing interaction amid the liquid and the interior pipe superficial.

- The higher disorder and the absence of hollows in which solid can gather mark flow pipes well right for slurry and mire facilities.

- Though, upkeep prices can be great if air exclusion cannot stop beavering of the pressure blow and lead outlines. Plunger expedients (opening detergents) can be fitted to occasionally eliminate accumulation from inner beginnings, even though the meter is connected.

- Lead outlines can also be substituted with button closure features hydraulically joined to the d/p spreader consuming full tubes. Complete measurement correctness can drip if the chemical closure is minor, its diaphragm is rigid, or if the tube scheme is not temperature rewarded or not protected from straight sunshine.

Venturi Principle and Bernoulli’s Equation

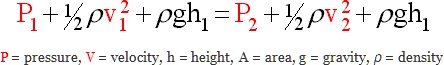

- Bernoulli’s Equation

- Venturi meter has a prolonged past of usages in several requests. Owing to its ease and reliability, the Venturi is amid the greatest mutual flow meters. With no affecting portions or sudden movement limitations, the Venturi can gage the rate of flow of liquid with a negligible entire pressure cost.

- The principle at which this meter works is Bernoulli theorem. The Venturi gages a liquid flowrate by dropping the moving liquid cross-section area of flow and producing a pressure alteration.

- Afterward, the pressure change is produced, the liquid is accepted over a pressure retrieval departure unit where up to 80 percent of the differential pressure produced at the throat is mended.

- Bernoulli’s Equation

Venturi Principle

- This principle says if the speed of fluidics then there is a decrease in inner pressure.

- WE can see in the above-given diagram that in the liquid arrives the Venturi at the position which has cross-sectional area A1, pressure P1, and speed V1.

- These belongings custom the potential and kinetic energy of the liquid at one place. Energy is conserved in a sealed scheme, which clarifies that adding of K.E and P.E at the same point is equal to the sum of both of them at the alternative point.

- If potential energy dribs at one place, the k.E necessity to proportionately upsurge at that place. The liquid currently arrives the gullet of the Venturi with a different area A2, which is lesser than first area A1.

- In a padlocked scheme mass can be neither produced nor devastated ( this law of conservation of mass, just says, what drives in, obligation to come out), and flowrate of fluid at first area A1 essential equivalent the flowrate at area A2.

- If the area at position A2is lesser than A1, the liquid will move quickly to preserve the similar flowrate. This upsurge in speed consequences in a reduction in pressure which works on Bernoulli’s Theorem. The consequence by significant pressure and cross-sectional area at two different positions, one can compute the speed of the liquid. With the speed of the liquid and its compactness, others can compute the rate of flow.

- A Venturi needs two pressures and one temperature calculation to precisely govern liquid flow. The main pressure is computed at the Venturi’s inlet position, P1. This is works for the density scheming and the great cross contribution to the differential pressure calculations.

Benifits Venturi Meter

- It decreases propelling prices.

- It has a low price compare to other venturi meters.

- It has no moving part and it can easily repair if a fault occurs at it.

- There is a need of insignificant square tube space necessities.

- Its brushoff ratio is10:1

- It has a repeatability of ± 0.1%

- It can be based in any location

- Its design is so simple which draws minimum pressure.

- features

- Now we discuss the features of the venturi flow meter.

- This meter delivers stability, fidelity, and works for a long time.

- It offers an un-adjusted precision of ±0.75 percent with repeatability of ±0.1 percent.

- Is intended in harmony to the same and iso criteria and it proposals the uppermost “as constructed” correctness.

- It decreases the propelling prices.

- It also offers the deepest level of enduring pressure damage of any venturi smartness, meaningfully fewer than orifice plates.

- It is a customary and exclusive amalgam,

- It provides a long-lasting elucidation for fluids, vapor, mist, and varied mediums.

- With slight alterations, the ssl can be distorted into a bi- steering movement meter.

- It can connects in any location with a negligible square tube.

- It also recognized as Herschel.

- Its working is like an RTD.