Hello, the friend I hope you all are doing great. In this post, we will have a detailed look at Introduction to Orifice Plate. An orifice plate is a module that is used for gaging of the rate of flow of different fluids, dropping pressure, or for limiting flow for these two works it is also known as a restriction plate. Moreover, a volumetric or mass movement rate can be measured, dependent on the scheming related to the orifice plate. It works on the Bernoulli’s theorem like the Venturi flow meter. This theorem says that there is a relation between the pressure exerted by any fluid and the speed of that fluid. This means if velocity increases then pressure declines.

Hello, the friend I hope you all are doing great. In this post, we will have a detailed look at Introduction to Orifice Plate. An orifice plate is a module that is used for gaging of the rate of flow of different fluids, dropping pressure, or for limiting flow for these two works it is also known as a restriction plate. Moreover, a volumetric or mass movement rate can be measured, dependent on the scheming related to the orifice plate. It works on the Bernoulli’s theorem like the Venturi flow meter. This theorem says that there is a relation between the pressure exerted by any fluid and the speed of that fluid. This means if velocity increases then pressure declines.

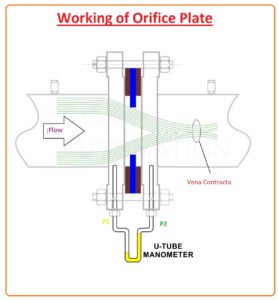

It is like a shrill plate with a hovel in it, which is typically located in a tube. When any fluid like water or gas moves by the orifice plate, its pressure constructs up somewhat up a tributary of the opening but as the liquid is required to join to permit over the hovel, the speed upsurge, and the liquid pressure declines. A minor downstream of the opening the movement scopes its point of supreme conjunction, the vena contracta somewhere the speed spreads its extreme and the pressure gets its lower point. Elsewhere that, the movement enlarges, the speed drops, and the pressure upsurges. By gauging the alteration in liquid pressure through tapings upstream and downstream of the orifice plate, the rate of flow can be gained from Bernoulli’s comparison by quantities recognized from the wide inquiry. So let’s get started with Introduction to Orifice Plate.

Introduction to Orifice plate

- An Orifice plate is a module that is used for gauging of the rate of flow of different fluids, dropping pressure or for limiting flow for last two works it is also known as a restriction plate.

- The orifice plate is a metallic disc with a concentric hovel in it, it is introduced into the tube which has moving fluid in it.

- This flow meter is simplest, less expensive, and exists in large no of different dimensions.

- As a result, these meters almost cover fifty percent market of volume flow rate instruments.

- One restriction of the orifice plate is that its imprecision is characteristically at least plus-minus two percent and can be near plus-minus five percent.

- The enduring pressure damage produced in the calculated movement is amid 50 and 90 percent of the extent of the pressure difference, (P1− P2).

- Additional difficulties with the orifice plate are a steady alteration in discharge constant above a time as the strident ends of the hovel attire away and a propensity for any elements in the curving liquid to twig after the hovel, thus plummeting its diameter progressively as the elements construct up.

- The concluding delinquent can be minimalized by an orifice plate with an eccentric hovel. If this hovel is near to the end of the tube, objects in the curving liquid inclined to be brushed over, and the accumulation of elements overdue the plate is minimalized.

- A very alike difficulty rises if there are any suds of gas or fume in the rolling liquid when fluid movement is elaborate.

- These also have the ability to make up

- These also tend to build up overdue an orifice plate and twist the design of the movement. This trouble can be dodged by mounting the orifice plate in a perpendicular route of the tube.

What is Orifice

- The orifice is a small size opening or hole that carries the fluid or gas. In industries and engineering terms an orifice is a specially created opening or hole used for certain operations like flow rate control of fluid or gas in the pipeline.

- Orifices are used in differnt devices and systems such as pumps, valves, and flow meters. The size and shape and location of the orifice have an effect on the operation and efficiency of the application where it applied

What is Flow Orifice

- The flow orifice is an orifice type that is designed for measuring the flow rate of gas or fluid in a pipeline. It comprises of accurately sized and shaped hole like a circle. It is installed at ninety degrees at the flow direction in the pipeline. As fluid or gas flows through the orifice it makes produces a pressure differential between the upstream and downstream sides of the plate that can be calculated and used for measurement of flow rate.

- Flow orifices are mostly used in industries for measurement of accurate flow and process control and optimization such as gas and oil generation.

- The structure and orifice size also pressure and temperature of gas or liquid must be accurately measured to make sure correct flow calculation.

Introduction to orifice plate flow meter

- The orifice plate flow meter is a flow meter type that uses an orifice plate for the measurement of the flow rate of gas or liquid in a pipeline. The orifice plate is a thinner flate plate with having accurate shape and hole in the mid, and it is installed at ninety degrees to flow direction. As fluid passes through the hole there is a pressure differential between the upstream and downstream of the plate that can be calculated and used for flow rate measurement.

- Orifice plate flow meters are mostly employed in industries where correct flow calculations are needed with that used for process control and optimization of chemical processing and water treatment. They are easily structured and less expensive than other types of flow meters. These flow meters also have some limitations as it is sensitive to changes in fluid and temperature and viscosity.

- To manage these limitations orifice plate flowmeters are combined with other instruments like pressure and temperature sensors to enhance accuracy and reliability.

What is restriction orifice?

- It is a type of orifice used to generate pressure drops in gas or fluid pipelines. It has an accurate shape and a sized hole-like circle shape. It is installed at ninety degrees to flow direction. The size of the restriction orifice is chosen carefully to make accurate pressure drops that can be used for differnt applications like flow rate control and protection of downstream devices

- Restriction orifices are mostly used in industries for projects where accurate pressure control is needed like water treatment and oil and gas. It is used in combination with other devices like valves and pumps for the regulation of fluid flow and protection against downstream damage. The desing and installation of the restriction orifice should be selected carefully and flow some factors like fluid properties, and flow and pressure drops

Orifice Plate Working Principle:

- When a fluid, whose rate of flow we are going to measure, is moved in the Orifice Meter, there is a pressure loss amid the inward segment and outward Segment of the Orifice plate.

- We can measure this change in pressure with any pressure measurement instrument such as an anemometer.

- Meanwhile, this difference in pressure is indirectly proportionate to the rate of flow according to Bernoulli’s Equation henceforth the pressure difference measurement instrument can be organized to show the rate of flow instead of displaying differential pressure.

- The operational standard of the Orifice Meter is similar, like that of the Venturi meter.

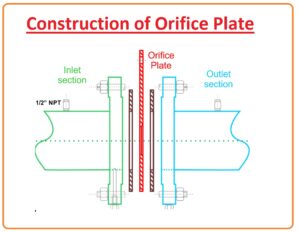

Construction of Orifice plate

- The main parts of the orifice plate are described below let’s discuss them one by one.

Inlet Section

- A linear ranging piece of similar dimensions as the inlet pipe for a conclusion joining for an inward movement linking. Here we calculate the inward pressure of the different fluids.

Orifice Plate

- An Orifice Plate is implanted in amid the Inlet and Outlet Segments to generate a pressure drop and therefore calculate the movement of the fluid.

Outlet Section

- It is the linear spreading unit like to the Inlet unit. At this point, the dimensions is similar as the outlet tube for an end link for a departing movement.

- At this point, we calculate the pressure of the fluid at the releasing point.

- As exposed in the diagram, a washer is cast-off to cover the place amid the Orifice Plate and the Overhang outward, stop seepage.

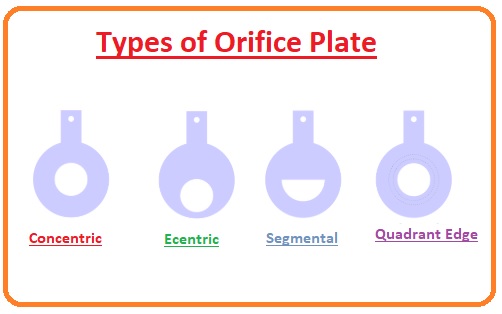

Types of Orifice Plate

Shape & Size of Orifice meter:

- Orifice meters are constructed in varied arrangements dependent on the solicitation’s definite prerequisite, The contour, dimension, and position of hovels on the Orifice Plate define the Orifice Meter properties as per the subsequent:

- Concentric Orifice Plate

- Eccentric Orifice Plate

- Segment Orifice Plate

- Quadrant Edge Orifice Plate

- Let’s discuss them one by one.

Concentric Orifice Plate

- It is prepared of SS and its dimensions fluctuate from 3.175 to 12.70 mm. The plate breadth at the orifice verge must not be surpassed by any of giving limits:

- 1 – D/50, here D is The tube inner diameter.

- 2 – d/8 here d is the orifice wiseacre diameter

- 3 – (D-d)/8

Eccentric Orifice Plate

It is alike to the Concentric Orifice plate other than the counterbalance hovel which is jaded at an angle to a sphere. It is usually engaged for gaging liquids that contain solids components, oily water, and drizzly steam.

Segment Orifice Plate

- It consists of a hole which is a semi-circle. The diameter is usually 98 percent of the diameter of the tube.

Quadrant Edge Orifice Plate

- This kind of orifice plate works for movements like unpolished oil, and higher viscous sauces. It is believably used when the line Reynolds Statistics from 100,000 or above or in between to 3,000 to 5,000 with a correctness constant of unevenly 0.5 percent.

Specifications of Orifice meter:

- Line dimensions of these instruments is 6 mm to 800 mm

- Its accuracy is from plus-minus 0.5 percent to plus-minus 3.0 percent.

- Its Working Temperature is Up to 800C

- Its Working Pressure is Up to 400 bar.

Applications of Orifice Meter:

- It can be used for Natural Gases.

- We can use it in different Water Purification Plants.

- It can be used in such plants where oil is filtered.

- It can also use in Petrochemicals and Factories.

Advantages of Orifice Meter:

- The price of the orifice meter is very low then other types of flow measurement instruments.

- It needs less space to work therefore it is the best choice for such applications where less space needs to work.

- Its Working retort can be deliberate with excellence.

- It can be installed at any position like horizontal vertical and tapper.

- Limitations of Orifice meter:

- It can definitely get blocked due to scum in gas or in indistinct fluids.

- The least pressure that can be attained for interpretation of the movement is occasionally tough to attain due to limits in the vena-contracta distance for an Orifice Plate.

- Dissimilar Venturi meter, down tributary pressure, cannot be improved in Orifice Meters. Complete head damage is about 40 percent to 90 percent of the differential pressure.

- Flow straighteners are obligatory at the in point and the out point to achieve linear movement thus enhancing the price and space for fitting.

- Orifice Plates can get certainly rusted with time so causes a fault.

- Its Discharge Coefficient gained is small.

So friends that is a detailed post about Orifice Plate, if you have any further queries, ask in the comments. Thanks for reading. have a nice day.