Hell readers welcome to new post. Here we will discuss How to Get High Quality and Low Cost PCB Board. PCB is very significant part of any electronic device and project that we make and used in normal life. PCB is the circuit boards that comes with the different layers has substrates material over which different layers of copper are positioned and symbolic representation are mounted where components are positioned to make project. There are different PCB designers and manufacturer are working in world and offered the different PCB based services.

That PCB manufacturers comes with different features and types of boards for their customers. There is one and only PCB suppliers best in world that offered the PCB based services on good rates with high quality. PCBWAY is china based PCB manufactures that has lot of features related to boards and different types of board. So here we will discuss how we can get the high quality PCB boards on cheap rates with good quality.

So let get started

What is PCB

- The PCB stands for printed circuit board, PCB is a thin sheet made of epoxy compound, glass-fiber, or various laminated materials.

- The rudimentary PCB (printed circuit board) consists of a smooth insulated substantial plate and a sheet of copper foil, covered with substrate.

- Chemical painting separates copper into different structures named by means or circuits of circuits.

- The body of the PCB (printed circuit board) has a cover that protects the brass from erosion and reduces the chances of a soldering short circuit between desks or an undesirable electrical connection with bare lines.

- Pcb contains many copper sheets. Two PCB coats contain copper coating on both sides.

- The adhesive PCB chip has additional copper sheets that are sandwiched between high-performance coating.

- The alternatives for the different sheets are connected to the vias (A via VIA or VIA is an electrical connection between sheets in a virtual electronic circuit that passes through one or more sheet planes from the end).

- If there are no components in the PCB (printed circuit board) then it is named as a printed cable board.

However, the term printed wiring board (PWB) has declined. - A multi-component PCB (multi-component circuit board) is designated as a printed circuit assembly, or (PCBA).

How to Get High Quality and Low Cost PCB Board

- There is one and only finest PCB supplier where high quality PCB with great features can get is PCBWAY.

- They always provides the services to their clients according to their needs and demands.

- Here i will guide you details process through which you can get the PCB from the PCBWAY.

Place Order at PCBWAY

- First of all make the Gerber files centroid and BOM of your project.

- For creation of Gerber file there is commonly used tool is Eagle with that or here software’s can be used.

- Centroid files helps to understands the features related the dimension of component that has to place on the board. PCBWAY has facility to mounted the components on both sides of boards.

- BOM files give the details of material used according to details of PCBWAY and this file should be in excel format.

- After completion of files needed we discuss the details procedure to get the boards from PCBWAY.

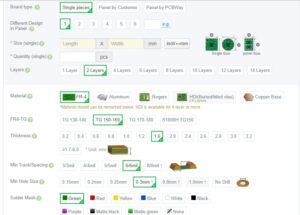

- First of all getting the board make account on PCBWAY site. When you login in the account press on the Instant quote tab on PCB site then different features can seen here.

When you fulfill the all required parameters with that there is some features also provided by PCBWAY such as SMD Stencil and PCBA services.

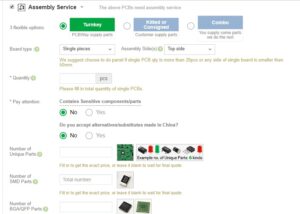

When you fulfill the all required parameters with that there is some features also provided by PCBWAY such as SMD Stencil and PCBA services.- To avail this features move to the Assembly tab and select the required option. Then choose select calculate and then resultant prices will be shown.

- The assembly layout can seen here.

When you will complete the Oder requirements there will be page open where you have to upload the required files such as Gerber, centroid and BOM.

When you will complete the Oder requirements there will be page open where you have to upload the required files such as Gerber, centroid and BOM.

- After that PCBWAY engineers will view the details of your Gerber and centroid files either they are accurate or have some error.

- If there is some changes has to made they will contact you and tell which changes has to made and also guide you about changes.

- After completion of details payments details will send to you and getting the required payments your desired product will create and send to you according to required time.

That is all about the How to Get High Quality and Low Cost PCB Board i have explained all details about the PCB and how you can get the best PCB with high quality and charges. If you have any further query ask in comments. Thanks for reading have a nice day.

When you fulfill the all required parameters with that there is some features also provided by PCBWAY such as SMD Stencil and PCBA services.

When you fulfill the all required parameters with that there is some features also provided by PCBWAY such as SMD Stencil and PCBA services. When you will complete the Oder requirements there will be page open where you have to upload the required files such as Gerber, centroid and BOM.

When you will complete the Oder requirements there will be page open where you have to upload the required files such as Gerber, centroid and BOM.