Hello, readers welcome to the new post. In this tutorial, we will discuss Construction of Double Sided PCB. The double-sided pcb is actually a very easy machine to build. All you need is a PCB that has been laid out, and the board itself. It is also possible to use different types of conductive materials in the side surfaces of the PCB. There are numerous PCB manufacturers are working in the world and offering different services related to PCB boards. The most reliable and high-quality PCB supplier is PCBWAY that can offer the PCB-related services they offered single as well, double-sided PCB boards with high quality and affordable features and requirements.

PCBWAY is located in China creating more than twenty-one hundred PCB boards pieces per day. They come with features of PCB prototyping, assembly designing with that CNC and three-D printing features in a single place.By investing in new tools, quality control, and user support, PCBWay provides quality services at very competitive prices. The company stands out for its support for a wide range of technology and an easy-to-use website, but above all for its strong community support

Another popular tool on the PCBWay site is a list of the most common PCBs, price by volume measurements, and other parameters found in the easy-to-read chart. This allows consumers, for example, to freely estimate how much it will cost to order 100-layer PCBs or 500 aluminum boards.Each service has its place on an accurate website but can still be easily accessed from the main web page. Once you have used the service of your choice, a quick quote can give you an estimate of the cost of your project and direct you to the official order form used to request a formal, detailed quotation.

Another popular tool on the PCBWay site is a list of the most common PCBs, price by volume measurements, and other parameters found in the easy-to-read chart. This allows consumers, for example, to freely estimate how much it will cost to order 100-layer PCBs or 500 aluminum boards.Each service has its place on an accurate website but can still be easily accessed from the main web page. Once you have used the service of your choice, a quick quote can give you an estimate of the cost of your project and direct you to the official order form used to request a formal, detailed quotation.

2. Advantages of Double-sided printed circuit boards over single-sided PCBs

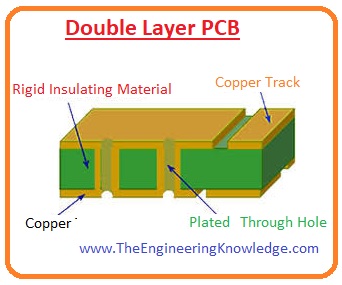

- The double-sided printed circuit board (DSPB) is a type of printed circuit board that combines both sides of the PCB (printed circuit board), for example, a single-sided PCB with two layers on both sides.

- The DSPB has the advantage over single-sided PCBs in that the conductive material on both sides of the PCB is up to 4 times thicker than on a single-sided PCB.

- The construction and process of printing using double-sided printed circuit boards are also called as double-layer pcb boards.

- A DSPB can be constructed either by a stencil method or by the production method according to the type of component parts.

- A stencil is an assembly method where the component parts are generally soldered or ground to the substrate at the component production line and routed through all assembly processes such as bending, crimping, bending, soldering etc.

- The production method is an assembly method where component parts are mechanically fabricated using an extrusion die machine (EDM) or directly by 3D printing, laser cutting etc. In this case, there will be some space between component parts in order to provide mechanical support for components during the manufacturing process.

- The advantage of DSPB over SPCB is its higher thickness and more conductive material; however, it has lower thermal conductivity compared with SPCB. Furthermore, DSPBs have higher manufacturing cost compared with SPCBs due to its multiple passes and complex structures.

- In general terms, DSPBs are used for high-volume applications such as mobile phones, co-ax cables, etc . A large number of components such as ICs , diodes, resistors, capacitors, inductors, etc can be mounted directly on the printed circuit board without any extra components being required to be mounted manually on top of it by hand provided that they can withstand high temperature and humidity conditions which can cause them to fail prematurely while mounting it onto substrates made from glass fiber/polymer/cermet/epoxy resin materials.

- As a result of this feature, they have many advantages over SPCBs especially when they are used in high-power electronic products like mobile phones / digital signage/computer LCD / computers because they can handle higher performance requirements even at higher temperatures and humidity conditions faster than SPCBs.

- Such advantages include increased reliability and safety factors due to their open structure; lower production costs; reduced weight distribution resulting from smaller size; higher life expectancy; better thermal con

Types of double-sided printed circuit boards

- Double-sided pcb board construction is a technology used in the production of printed circuit boards, wherein one surface of the board is double-sided, that is, both surfaces are provided with a conductive material such as copper and aluminum.

- The double-sided pcb board can be used to manufacture many types of devices ranging from ICs (integrated circuits) to semiconductors (electronic components).

- The quality that makes a double-sided pcb board an excellent choice for manufacturing applications is its ability to withstand high temperatures and electrical stress. The board can also maintain its properties even when subjected to corrosive environments and corrosive chemicals.

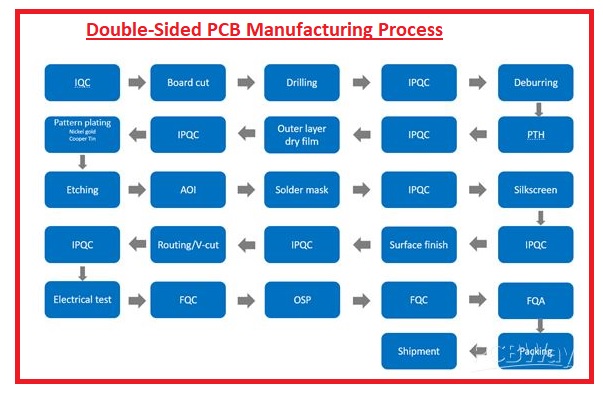

Double-Sided PCB Manufacturing Process

- Double-sided printed circuit board (PCB) fabrication is a process in which the two sides of a PCB are constructed as one unit and are then joined together. There are two types of double-sided PCB manufacturing processes:

1. The first type is the dry run process, in which the PCB assembly is completed in one pass through a press.

2. The second type is the wet run process, in which the PCB assembly is completed with a pre-assembled die on both sides.

The primary benefit of using this technique over traditional single-sided manufacturing techniques is that it allows for higher yields and faster times to market.

- The wet run style of manufacturing can also improve component density and layout density on the board. This achieves better ease of access to important circuit structures and components that may be difficult to assemble correctly when using a dry run process. The wet run style can also be used to integrate connectors between layers of a multi-layer PCB, as well as link several layers together in an integrated configuration (a single Substrate).

Conclusion

The information in this short training course is based on the following four factors to be considered for your decision about selecting double-sided pcb board construction:

1) Diameter of the printed circuit board.

2) Number of pieces of components to be mounted on the printed circuit board.

3) Soldering and tinning technique used for wiring, as well as the material used for bonding.

4) Cost of PCB manufacturing and assembly.

The most important factor to consider when selecting a feature-rich double-sided printed circuit board is its size, which determines how many components can be mounted on it. In addition, the type of materials used in the board should be considered because they will affect the cost of manufacturing it. The most common materials include copper and aluminum. The latter is usually more expensive than copper, but still provides better electrical performance which makes it an attractive choice for many applications.

There are also other factors that must also be taken into account when considering double-sided pcb board construction:

1) The cost of manufacturing PCBs. Note that cost depends on several factors such as technology used, materials used and quantity produced. Generally, a higher number of pieces can reduce costs significantly; however, this depends on various factors including manufacturing technology (automation vs manual), quality control level and mass production capability.

2) Material costs. Because multiple materials are typically used in PCBs manufactured by different companies and sometimes even by different suppliers from one country to another , prices vary widely depending on these factors.

3) Board size . This depends on several factors such as material type (e.g., copper vs aluminum), component count (e.g., 30 vs 30+ 20+ 10+ etc.), design complexity (e.g., simple vs complex), yield rates (e.g., high or low), etcetera .

4) Circuit complexity. This depends on many things including component count (how many chips do you want to mount?), layout complexity, component placement accuracy, thermal performance, etcetera .

5) Cost per piece . This depends mainly on component count but also includes other factors like layout complexity, component placement accuracy, thermal performance, etcetera .

6) Selection criteria. These include technological advancement from one company to another company or even from country to country; choosing a supplier based mainly or only on price rather than quality; choosing a supplier with low overhead as opposed to high overhead; choosing a supplier based mainly or only on time rather than