Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, I am going to explain Winding Insulation in Ac Machine. The windings either of the stator or rotor of the alternating current machines are the most sensitive portion. If due to some certain environmental or internal faults windings of the machine damage it causes serious disaster for the electrical machine. Due to damage to the windings lots of money will be spent to make insulation proper and repairing the winding. For the protection of the insulation of the windings, it is essential to run a machine at limited temperature conditions.

Hello, friends, I hope all of you are enjoying your life. In today’s tutorial, I am going to explain Winding Insulation in Ac Machine. The windings either of the stator or rotor of the alternating current machines are the most sensitive portion. If due to some certain environmental or internal faults windings of the machine damage it causes serious disaster for the electrical machine. Due to damage to the windings lots of money will be spent to make insulation proper and repairing the winding. For the protection of the insulation of the windings, it is essential to run a machine at limited temperature conditions.

The constraint of the working temperature of the machine will also affect the performance of the machine and it will reduce the power of the machine. In today’s post, we will have a look at different parameters of the insulation, its classes and how we can operate machines without damage the insulation and windings. So let’s get started with Winding Insulation in AC Machine.

Winding Insulation in AC Machine

- In some certain cases when there is a sudden increment in the temperature of the winding it will damage the insulation of the windings.

- But normally in the increment of temperature will damage the winding’s insulation very slowly and not effect like the above mention effect that occurs in certain conditions.

- Instead of the temperature, the windings’ insulation can also damage due to the sudden jerk on the motor, trembling or electric pressure.

- There is a conventional rule that says if a 10 percent increment in the rated temperature of windings occur it will reduce the fifty percent life of the insulation of the windings. This rule is still valid for the insulation’s life measurement.

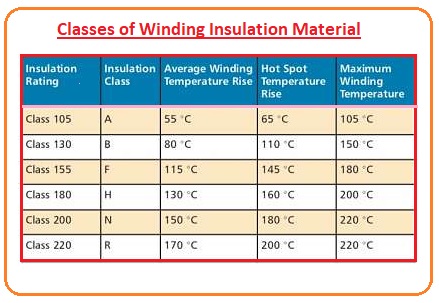

- According to the temperature, NEMA (National Electrical Manufacturers Association) has divided insulation into the different classes.

- Every class has a certain value of the temperate increment of the insulation that can be bearable for the insulation class.

- National Electrical Manufacturers Association has 3 different classes for the different alternating current motors. That is B, F, H.

- Every class specifies a certain value of the temperature that if occur then the windings will work in a safe condition.

- For instance, in class B the temperature limitation will be eighty degrees, for F one hundred five degrees, and class H it will be one twenty-five degree.

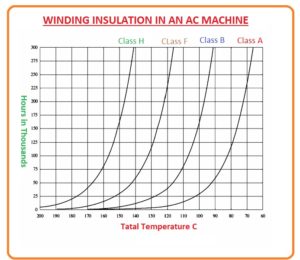

- The temperature increment effect on the windings is behaving dramatically. The given diagram show this behavior.

- This figure shows the mean life of a machine in 1000 hrs. vs the temperature of the windings, for numerous classes.

Insulating Materials and Their Properties

- Insulation is the heart of the machines, so the material of the insulation such that it can bear any type of effect of temperature or pressure observed by the thermal, mechanical or electric.

- To bear all these effects it should have some specific types of properties that are described here.

Electrical stresses

- The insulating material should have a larger value of the break-down voltage to bear electrical stress.

- Its working performance should be for a longer time interval.

- It should have less value of the fractional discharging.

- The leakage current form that material should be lesser.

Thermal Stress

- There should be smaller shape alterations in case of temperature variations.

- The internal destruction of the insulating substance should be less.

Mechanical stresses

- The structure of the insulation such strong that it can bear any external force without any damage.

- It must have a minimum lessening of mechanical strength within certain working temperatures and voltage.

Classes of winding Insulation Material

- The main classes of the insulation material are described here let’s discuss them with the detailed.

Winding Insulation class A

- This type of insulation material is created by the paper, cotton, silk, etc. after creation, they are coated with an insulating liquid.

- The varnish on theses martial avoids them from absorbing the water.

- Normal substances in this class are glazed cloth and oil-impregnated paper.

Winding Insulation class E

- These material comprises cable varnishes on a base of polyvinyl recognized, polyurethane or epoxy gums as well as molding powder plastics on phenol-formaldehyde and comparable folders, with cellulose plasters, coated plastics on paper and cotton material base, triacetate cellulose sheets, sheets and fibers of polyethylene terephthalate.

Winding Insulation class B

- These comprise mineral constituents like mica, glass fiber, and asbestos, etc., soaked or pasted together with lacquers including normal organic materials for heat confrontation like oil-modified synthetic mastics, tar, shellac, and Bakelite.

Winding Insulation class F

- These materials comprise mineral constituents like glass fiber and mica soaked or pasted together with epoxy, polyesterimide, polyurethane or other mastics having larger thermal strength.

Winding Insulation class H

- These material includes compound materials on mica, glass fiber and asbestos bases, soaked together with silicone mastics or silicone elastomer.

- These constituents must not comprise any carbon-based fibrous ingredients like paper or cloth which is discussed in class B and even F insulations.

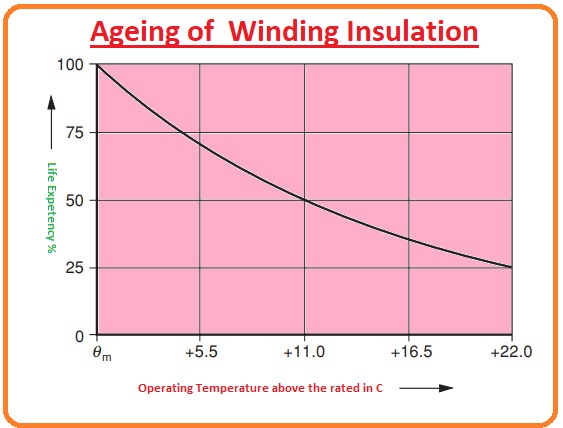

Aging of Winding Insulation

- With the passage of the time as the machine becomes older the insulation of the windings transformed into the fragile and shrinks, which leads to cracking in the insulation.

- With the increment of temperature running life of the insulation also decreases.

- The life of insulation remains half with the eleven-degree increment in the temperature of the rated value of the windings’ temperature.

- Occasionally the mass of the machine can be only minimal when it was firstly selected and with the time, it can be essential to do some work that is too difficult.

- Due to the overheating, the insulation depreciates, and it is known as thermal aging of insulation.

- The given figure demonstrates a rough decrease in life hopes with a rise in functioning temperature.

So friends that is the detailed tutorial on the Winding Insulation in AC Machine I have mentioned each and everything related to this post. If you still have any query ask in comments I will resolve your queries. See you in the next tutorial.

I believe this is among the most significant information for me.

And i am satisfied studying your article. However should

commentary on few basic things, The web site style is great,

the articles is actually nice Excellent activity, cheers

Dear sir,

I am very happy and satisfied for your the most significant information. I will introduce myself to you,

i am one of an instructor of marine engineers in MYANMAR. So, i always to study for marine technologies.

I share all knowledge and technological theory to all marine students. Among all browsers your web site is

the best for me, thank you so much, bye.