Hello, readers welcome to the new post. In this post, we will discuss WHAT IS PCB Panelization. PCB board is very commonly used in industry and any electronic device. These boards are created through the use of different techniques and features. Commonly used techniques for PCB manufacturing are SMT and through holes. Through SMT techniques components are mounted on the surface of the board while in the case of through-hole leads of components are passed through holes and get soldiers.

Hello, readers welcome to the new post. In this post, we will discuss WHAT IS PCB Panelization. PCB board is very commonly used in industry and any electronic device. These boards are created through the use of different techniques and features. Commonly used techniques for PCB manufacturing are SMT and through holes. Through SMT techniques components are mounted on the surface of the board while in the case of through-hole leads of components are passed through holes and get soldiers.

PCB Panelization is a process through which more than one design of the board is created in a single board that can be used for more projects through time-saving and less cost. A board that has more than one small board is called Panel and this process is called panelization. In this post, we will discuss the different features and parameters of this process and also explain to you how you can get the PCB panels form JLCPCB which is the best PCB supplier. So let’s get started.

WHAT IS PCB Panelization

- PCB panelization is a technique through which small-size boards of a single design are created and linked in the shape of the array in a single board.

- After the creation of the panel, all boards can be separated according to use of this process called depanlization.

- This process helps to make fewer defective boards since automated assembly machines face less errors. With that panelization process also reduces the expenses also makes in less time interval.

Techniques for Panelization

- There are different types of PCB panelization are used on basis of their features. The design of boards is also taken into consideration during the panel creation. Some factors were also noted for panelization.

Board design

- PCB design takes part for the creation of the PCB panel. The layout of some components is such that not fit for board areas so there must be a proper design is created to make accurate panelization.

Components

- Components attached on the are also main factors since some component re not easy to connect and has sensitive natures for PCB panelization.

Material

- There must be some materials that are used for the fine panelization process. Because some materials have a nature to easy breaking get damage when are separated from panels. With that thickness of materials also noted to apply the easy panelization techniques

- The 3 main techniques used for PCB panelization are discussed here

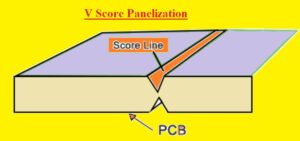

V Score Panelization

- There are V-shaped grooves used for the separation of PCB from the panel. The grooves separated 3rd of board thickness at the upper and lower parts of the board through an angled blade.

- For breakout, a process machine is used through making sure that the remaining part of the board among the grooves is hard and hand breaking can apply pressure at the PCB and other components

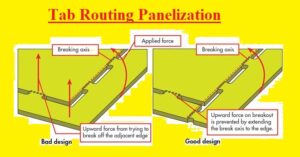

Tab Routing Panelization

- In this technique, PCBs are cur from the panel and placed on boards through the use of perforated tabs. 3 to 5 holes are used for the perforation pattern. This technique is used to support of design through edge hanging components.

Solid Tab Panelization

- Panels can be made by putting the solids tab among the boards that enhance the strength. For such a board to break out there is a need of depaneling router and laser cutting machine. The routers can result in dust and vibration but a laser cutter is costly and not good for boards having a one-millimeter thickness

Difference between V-SCORE and TAB ROUTING PCB PANELS

- The use of V score or tab routing depends on the design of the PCB. Here are some factors that define which method has to use.

Board structure

- The shape of the board existing in the panel helps to panelized the board. For square and rectangular boards V scoring is used and for other designs, tab routing is used

Components placement

- If components are lies closer to edge or placed on the edge tab routing is used than V scoring

Quality of Edge

- On the basis of edge quality, tab routing is preferred. with the use of the process left small rough nubs of lamination that can be discarded and other parts of the edge make smooth through routing.

Time comparison

- Tab routing takes more time also working persons while V scoring takes less time

Material loss

- Material waste is more for tab routing than v scoring

How do I order a panel? JLCPCB

- JLCPCB is an experienced and expert PCB supplier working in China. They are providing PCB-based services since 2006. You can get a two-layer PCB board in two dollars with five pieces. four-layer PCB can get five dollars. SMT stencil service in seven dollars for one piece from JLCPCB

- JLCPCB sought to increase efficiency and reduce costs. They promise to offer customers the most economical PCBs forever. JLCPCB produces the cheapest yet high-quality PCBs, probably due to economies of scale, extremely high production efficiency, and lower labor costs.

- In the below figure you can see that five-millimeter board edge through the default setting and there are two rows and five column panel PCB

- Make sure that the size for a single PCB is larger than 1.5cm x 1.5cm or you will have to pay $14.5 for the v-cut cost. Since small PCBs are difficult to V cut.

- Also, make sure that the outline for the board is simple in case of complicated board outlines you need to penalize by yourself.

.PCB Panelization Advantages

- PCB panelization process not only helps to make smaller boards but also increases efficiency. Some benefits of this process are discus here

Standard PCB Size:

- It helps to make less expensive boards through use of manufacturer standard processing panel

Efficiency

- This process is speedy and efficient since from paste printing to the assembly of components, soldering, and testing each is performed efficiently.

Save Products Creation

- Panelization protects the boards from vibration and high-pressure damage

Mass Production

- Through the use of PCB panelization larger numbers of Panels can be created at fewer prices and les time

That is all about the PCB Panelization all details has been explained. Further, if want to get the PCB Panelization services for your projects must consult JLCPCB. which is the best in all services.