Hello, readers welcome to the new post. In this post, we will discuss What is Kapton PCB. PCB has different types according to features and applications. Kapton PCB is type of polyimide PCB. To have details understanding of Kapton PCB have info of polyamide PCB. The combination of diamine monomers and dianhydride under a condensed state creates polyamide. There is a covalent bond exists between nitrogen in the carbonyl groups. Polyamide is used in different applications such as high-temperature values stiffness and high rate strength applications.

In 1960 dupoint created the Kapton that bears the temperatures values at different levels. So it is used in different projects. Kapton is high conductive polyamide. Its main function is to control the heat existing in the device. Its common applications are aerospace, wind turbine, and automotive. With the Kapton as well polyamide PCB you can get the different types of PCB boards from PCBWAY. It provides the different features and services related to PCB board to their customers. It is located in the heart of the world’s production capital; In Shenzhen, PCBWay has been delivering high-quality sophisticated PCBs using state-of-the-art technology since its inception ten years ago. They have served as a trusted partner of PCB Manufacturing in a number of small or large-scale operational projects in a variety of fields, from IoT and Smart devices to medical industries, Industrial units, and Open source.

Using one of the world’s most advanced industries, PCBWay manufactures a wide range of PCBs from standard FR4 PCBs to flexible PCBs, SMD stencils, and highly advanced, precision PCBs. They are capable of making up to 14 layers of PCB (depending on the type of PCB) with materials ranging from FR4 to Aluminum. More information on their PCB skills and equipment specifications can be found on their service description page.

Introduction to Kapton PCB

- Printed circuit boards (PCBs) are where the conductive tracks such as tracks and trace laminated with copper are used to automatically support and connect electronic components.

- Printed circuit boards are therefore designed to support the means of electrical equipment. All electronic devices consist of printed circuit boards as this is a means of transmitting signals within the electrical appliance.

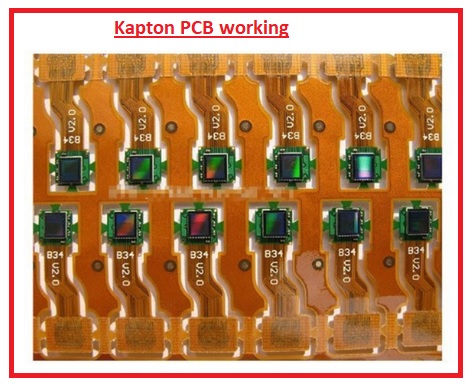

- Once you understand the simple printed circuits, then comes the flexible printed circuit boards. You can customize your own interface and depending on your needs a flexible printed circuit can be made using Kapton-like polyamide as a base material.

- The flexible printed circuit board is an additional type made using a thin layer of polymer film (i.e. Kapton) with a continuous tracking pattern on the substrate.

- In simples words, Kaptons is helping to increase the flexible nature of PCB.

- Flexible regions were introduced many years ago, somewhere after World War II and the industry is still determined to expand these circuits as much as possible. Electrical appliances are often exposed to extremely high temperatures. The device may be damaged if the proper equipment has not been used on it.

- To overcome this problem, polyimide should be used that can withstand rising temperatures. Since 1960, Kapton has been the best solution to this problem.

- The main reason for using Kapton on electrical devices is heat exposure. As we already know that heat exposure is a common hazard in the production of electrical devices and printed circuit boards. The temperature can exceed 400 Fahrenheit. Kapton is therefore a fire extinguisher and can expose temperatures of up to 700 Fahrenheit without affecting the visibility and performance of the label.

- Kapton is a highly flexible polyimide material and can withstand harsh conditions to provide functional circuit board labels at all times.

Features of Kapton PCB

- Kapton PCB is very helpful to endure the different temperatures ranging from low to high.

- It has the ability to sustain the electrical mechanical and physical features in a range of temperatures -452 to 752 Fahrenheit.

- It is used in aerospace due to its features of good resistive natural and insulators.

- It has the ability to show tolerance for heat and cold.

- It used in chemical industries due to handling of radiations

- It is used for the labeling process.

Kapton PCB Advantages

- Kapton PCB is employed in different applications. Its flexible nature makes it effective to use it in different products.

- It is used in different electronic devices to enhance their flexibility. It helps to reduce the assembly procedure.

- The movement of signals in the different devices can be improved through the use of this board.

- There is a thick polyimide film on the circuit substrate including copper foil. For small and light circuits or integrated and complex devices, the solution ranges from a single Kapton base circuit to multilayer or 3D Kapton printed circuit boards. Additional stability of machinery and power can be improved by strengthening the foundation of the circuit. In this way, the power of the cycle will also be increased.

- Due to the flexibility, Kapton circuits provide better power efficiency. There is a good flow of electrical signals due to the constant dielectric. After exposure to heat, parts can quickly cool off due to the beautiful thermal properties. In addition, the components can work very well under extreme temperatures due to the high transition of the glass.

Another major advantage of using Kapton printed circuit board is that you can reduce the size of the circuit boards needed for most applications. The thin size and low weight are required by many electronic devices such as laptops, computers, pieces of military equipment, aerospace, PDAs, peripheral devices, digital devices, mobile communications, and many other fields.

That is a detail about the Kapton PCB. I have explained different parameters about the Kapton PCB. If you have any further query ask in the comments. Thanks for reading have a nice day.